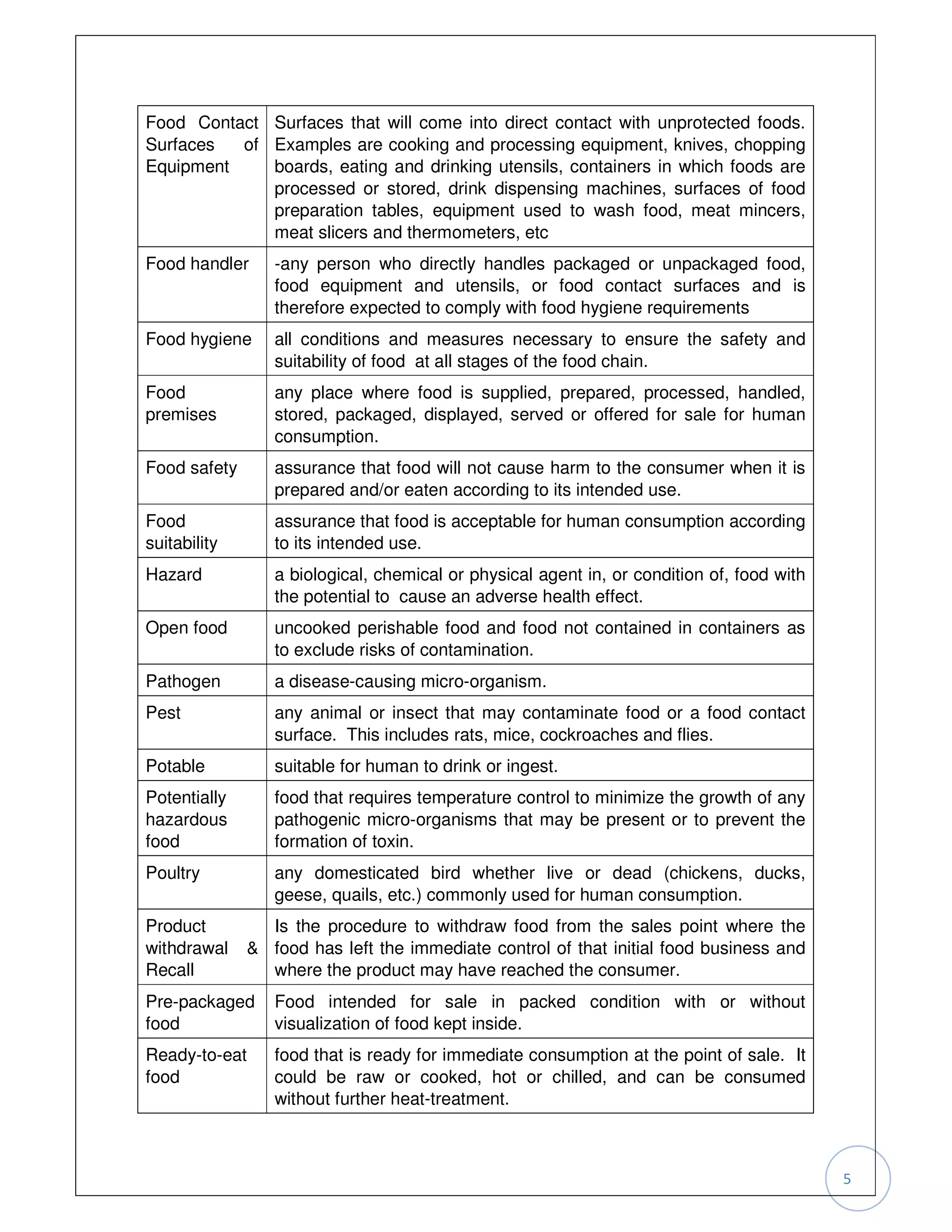

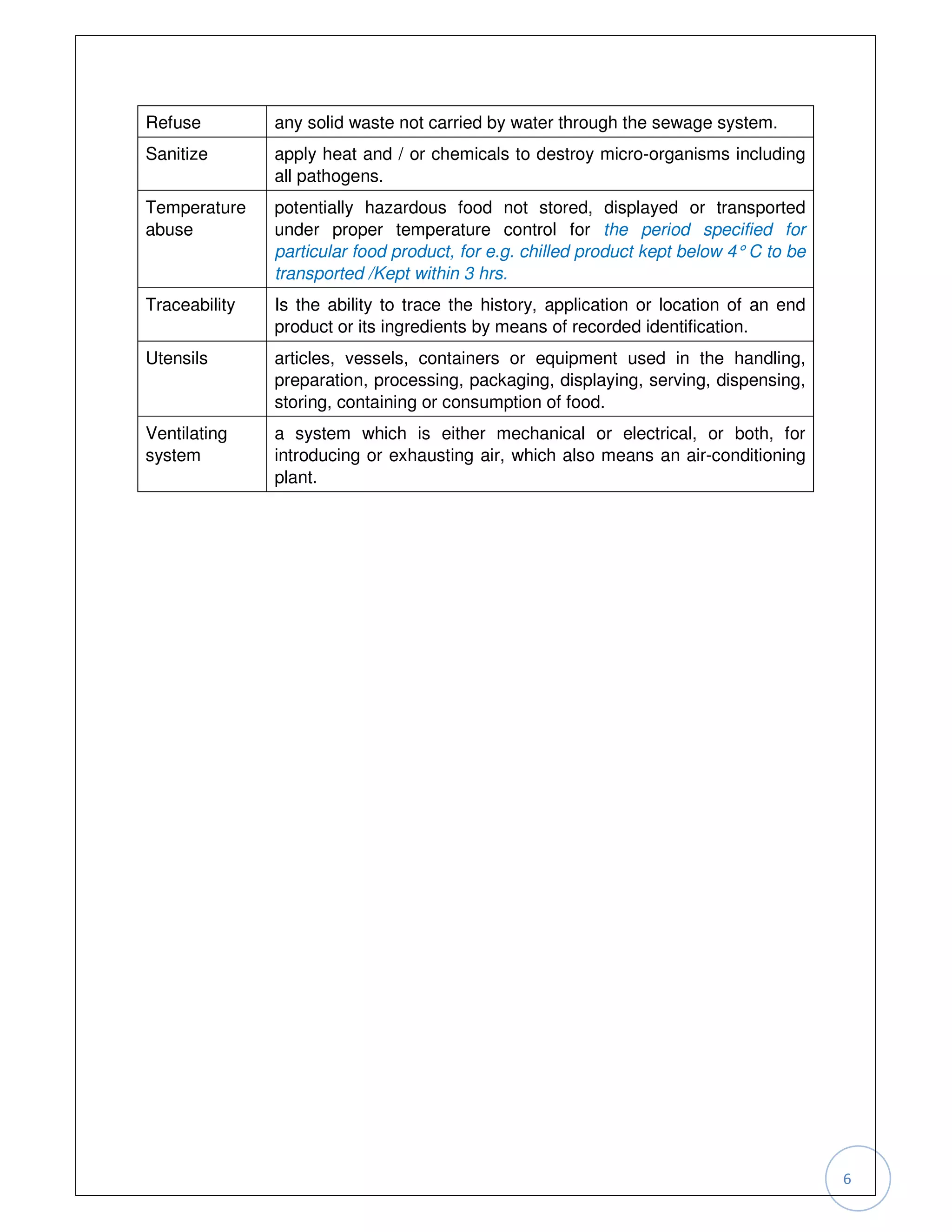

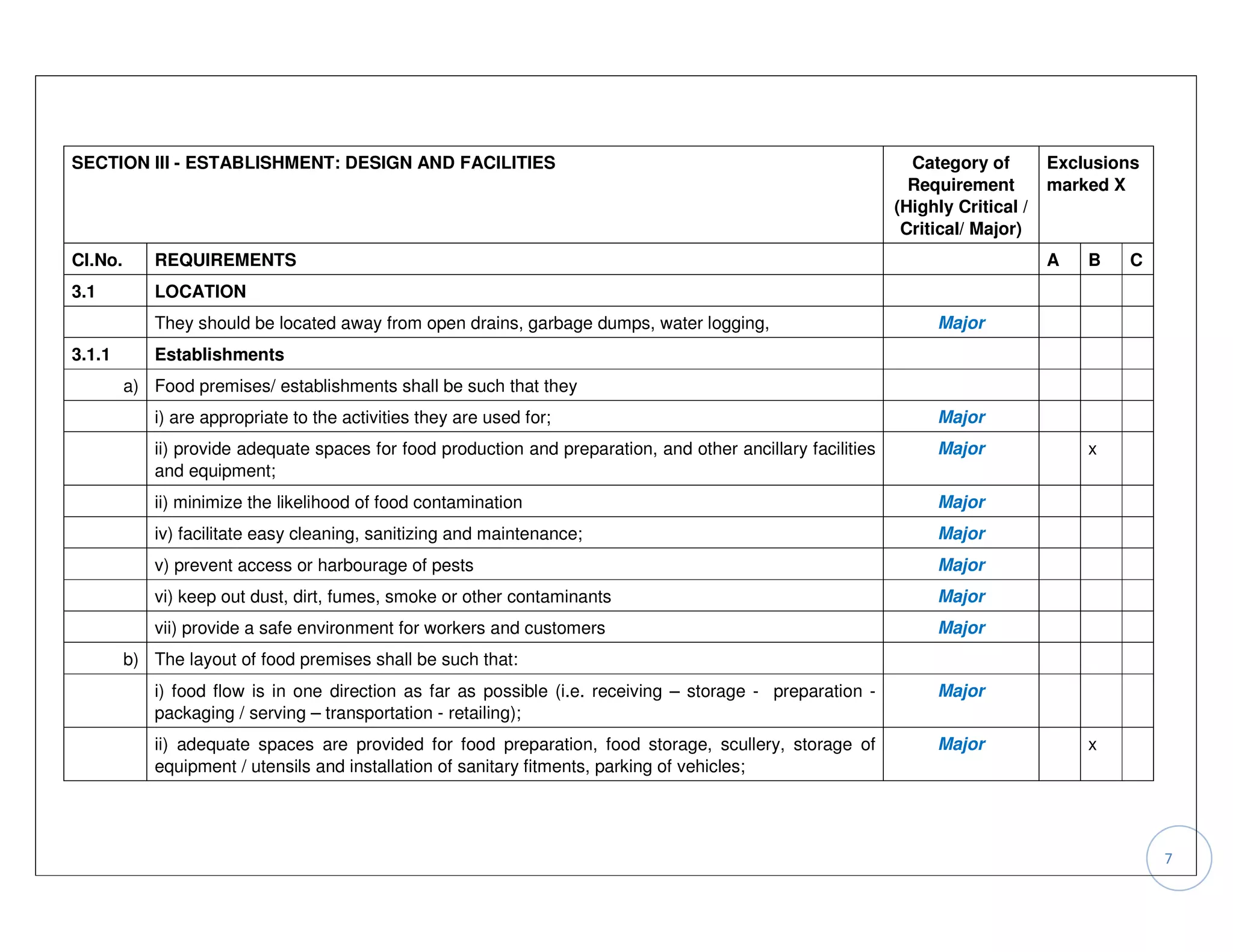

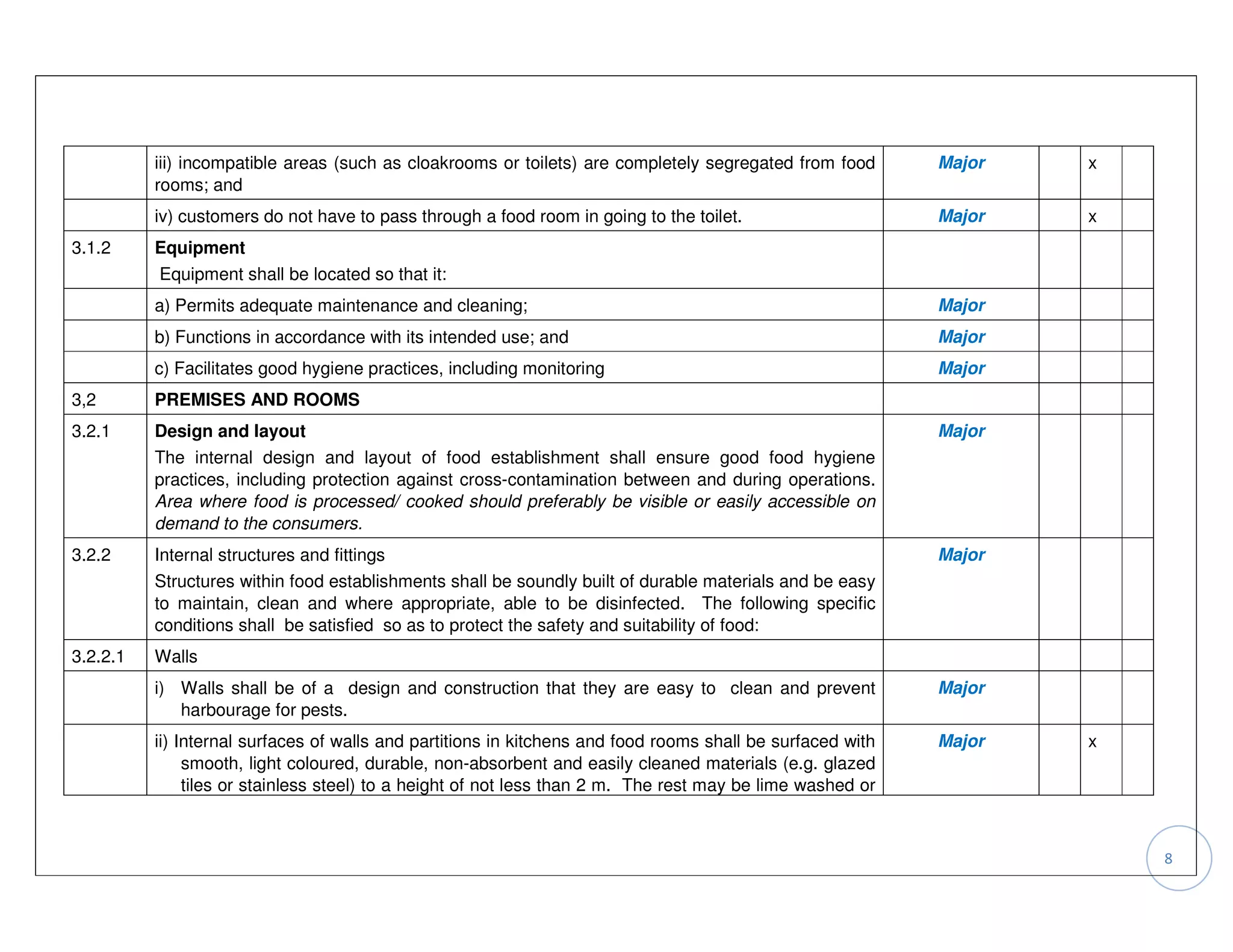

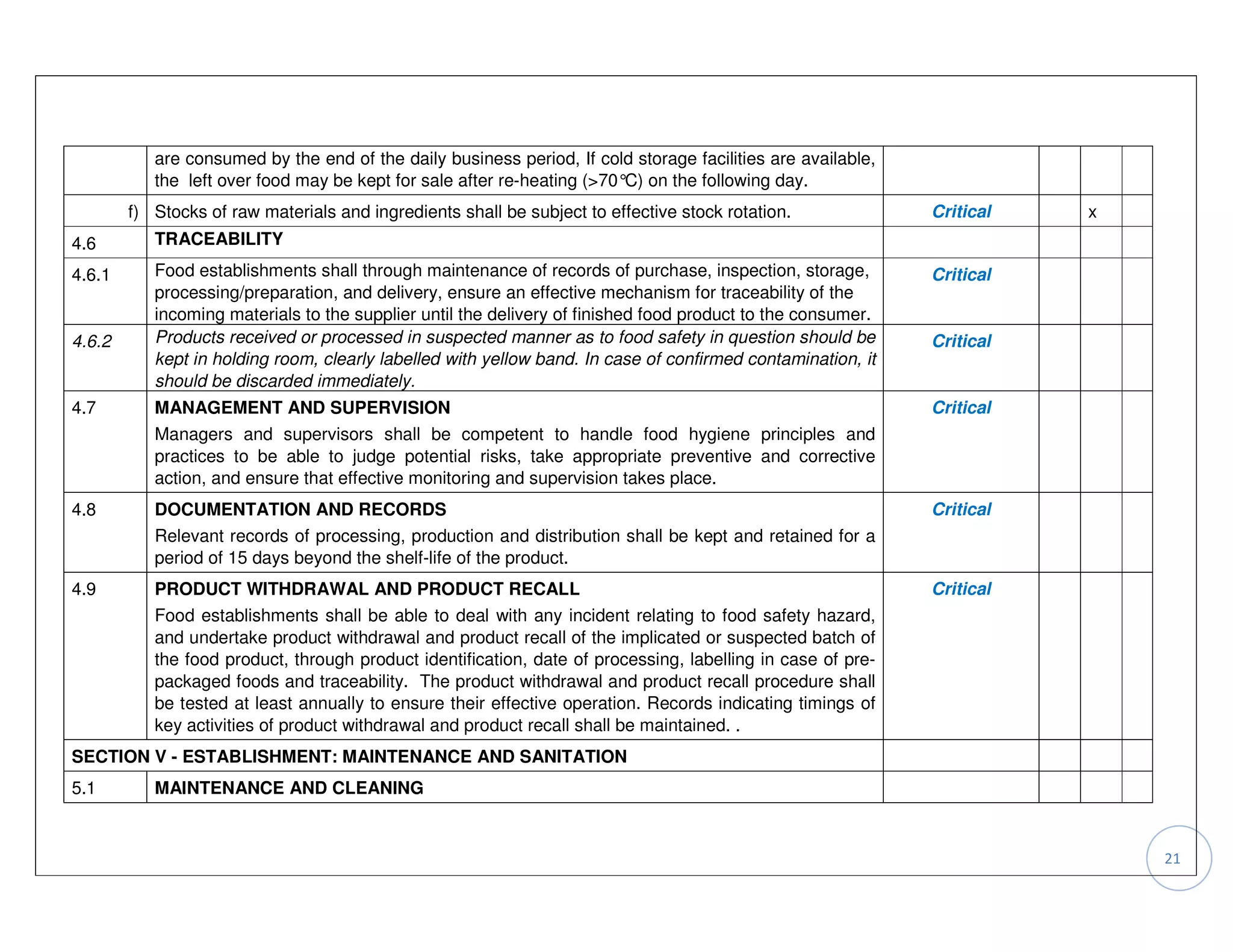

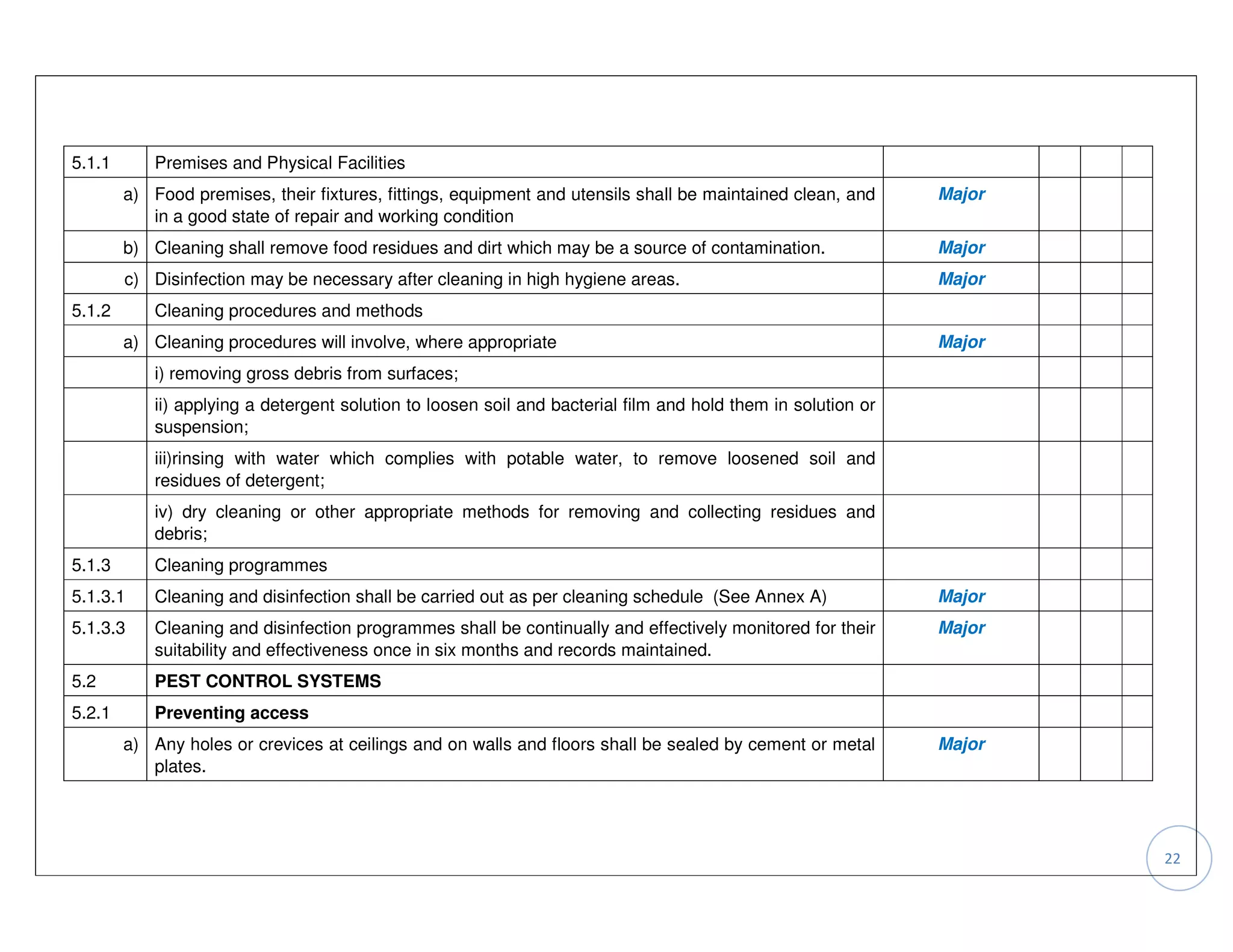

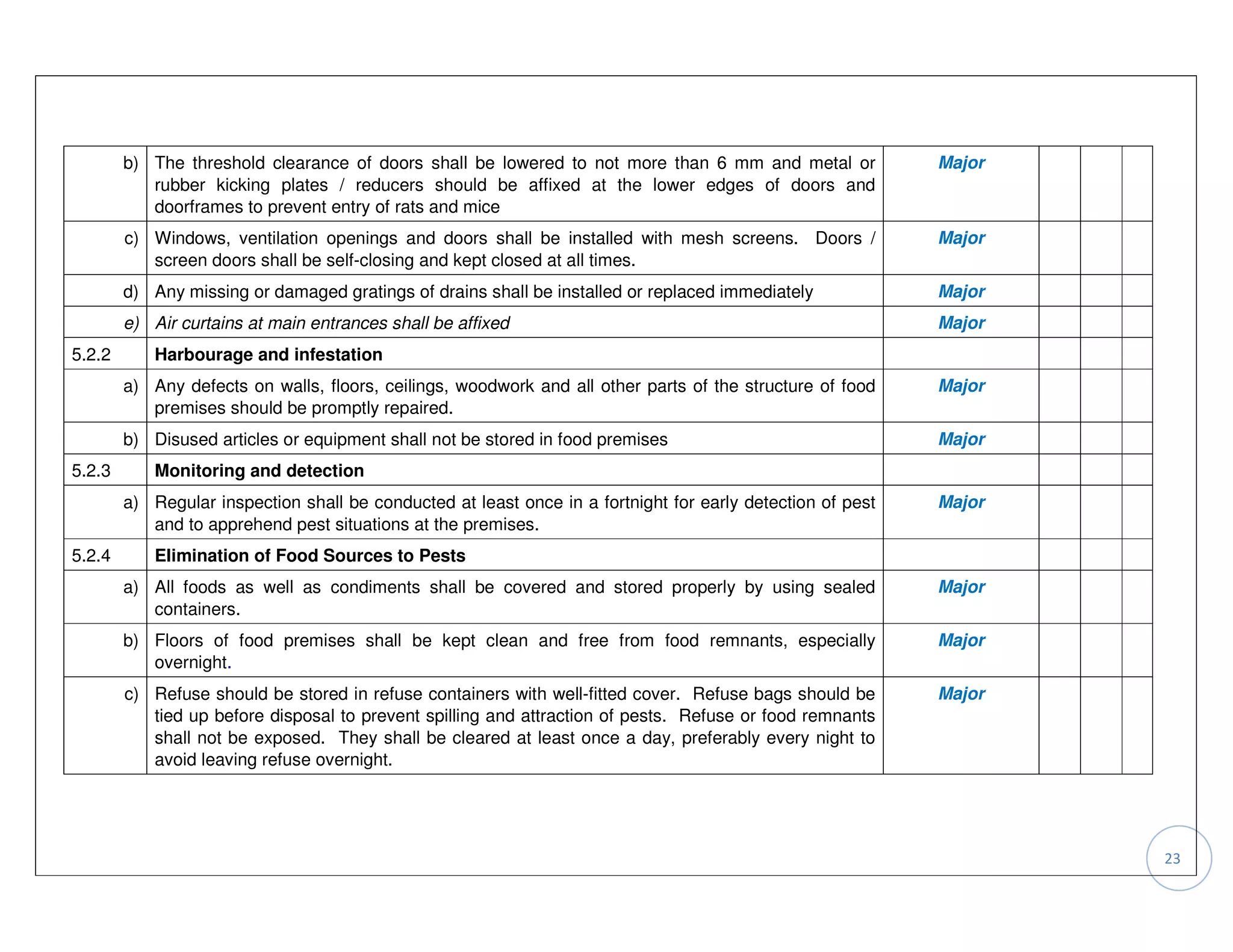

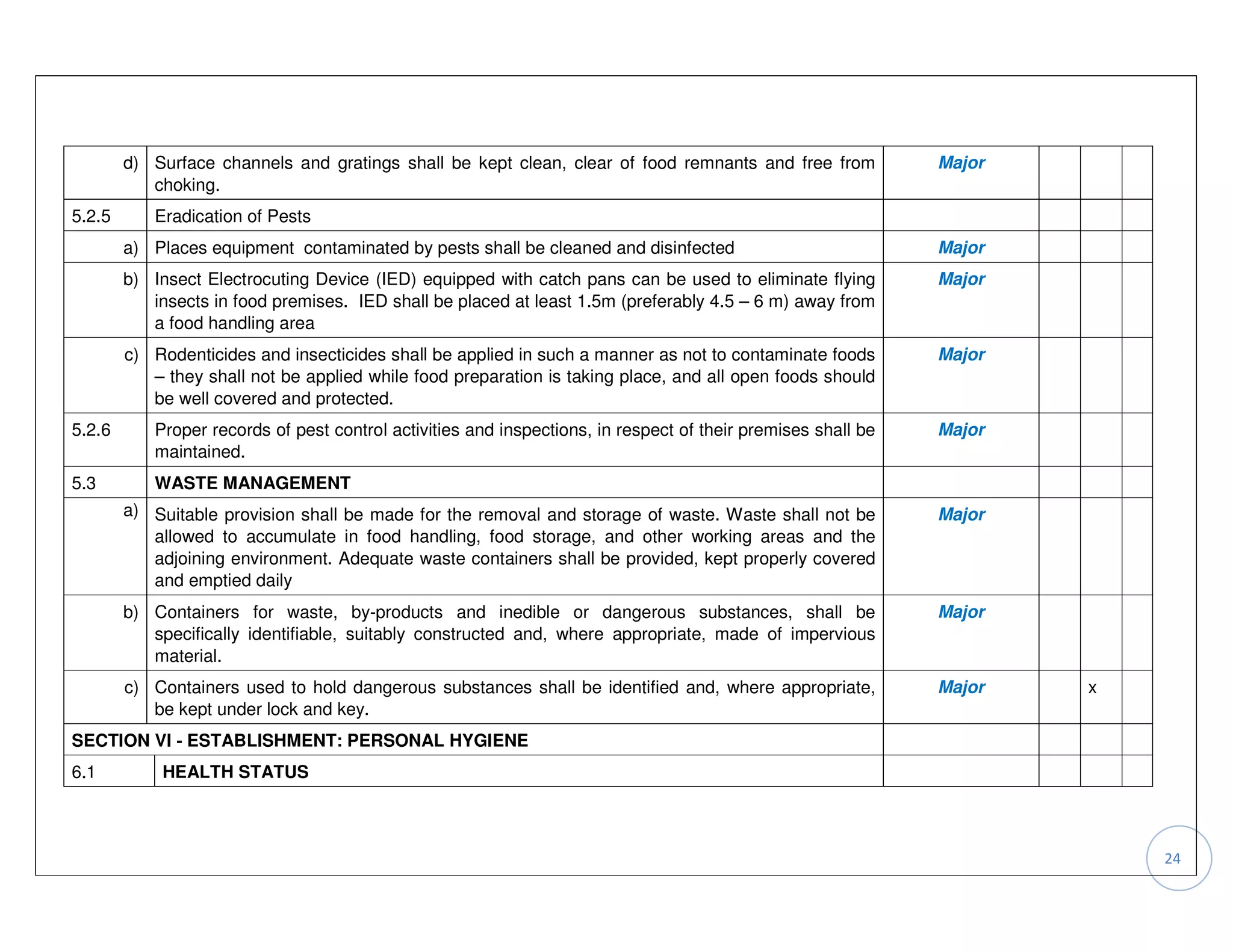

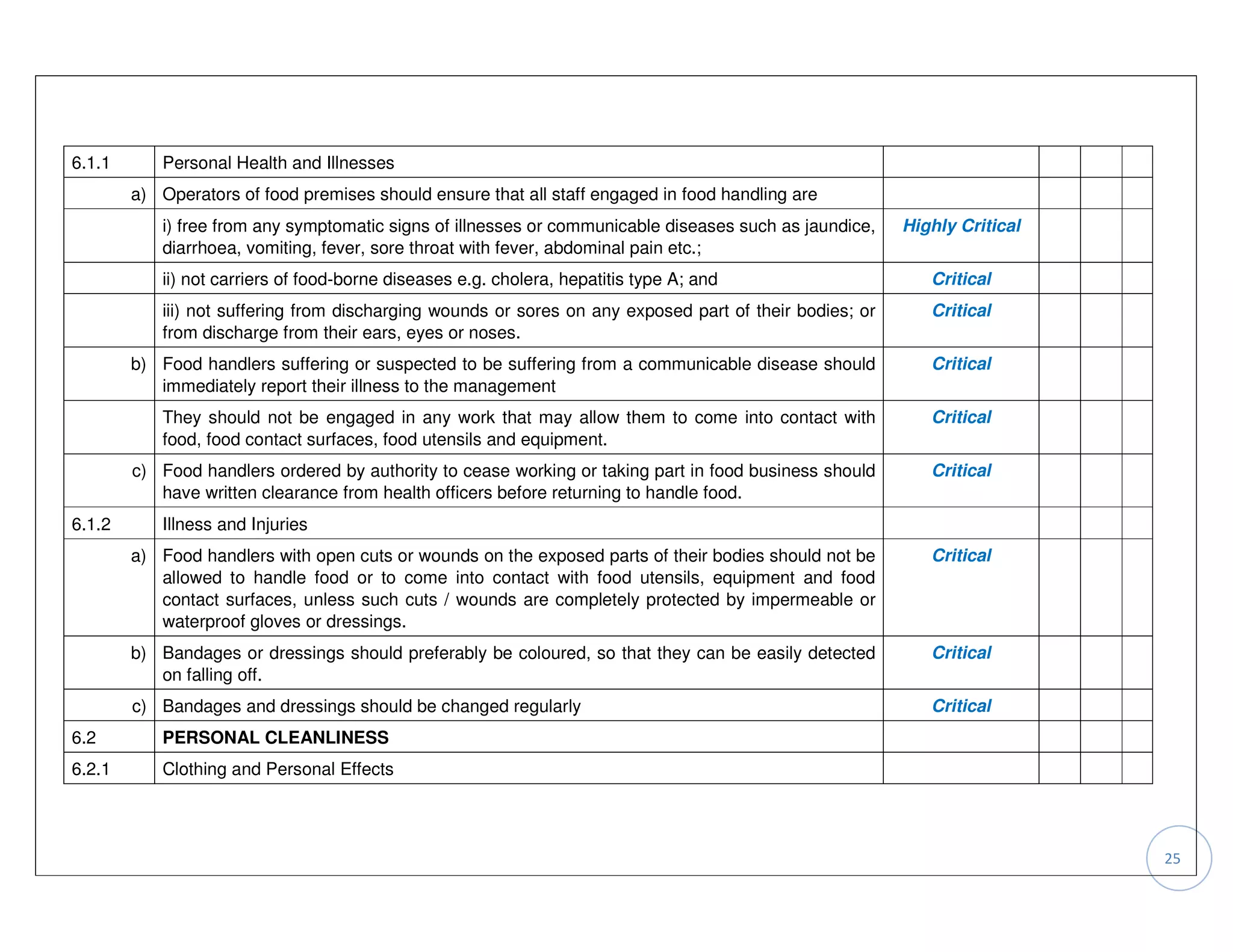

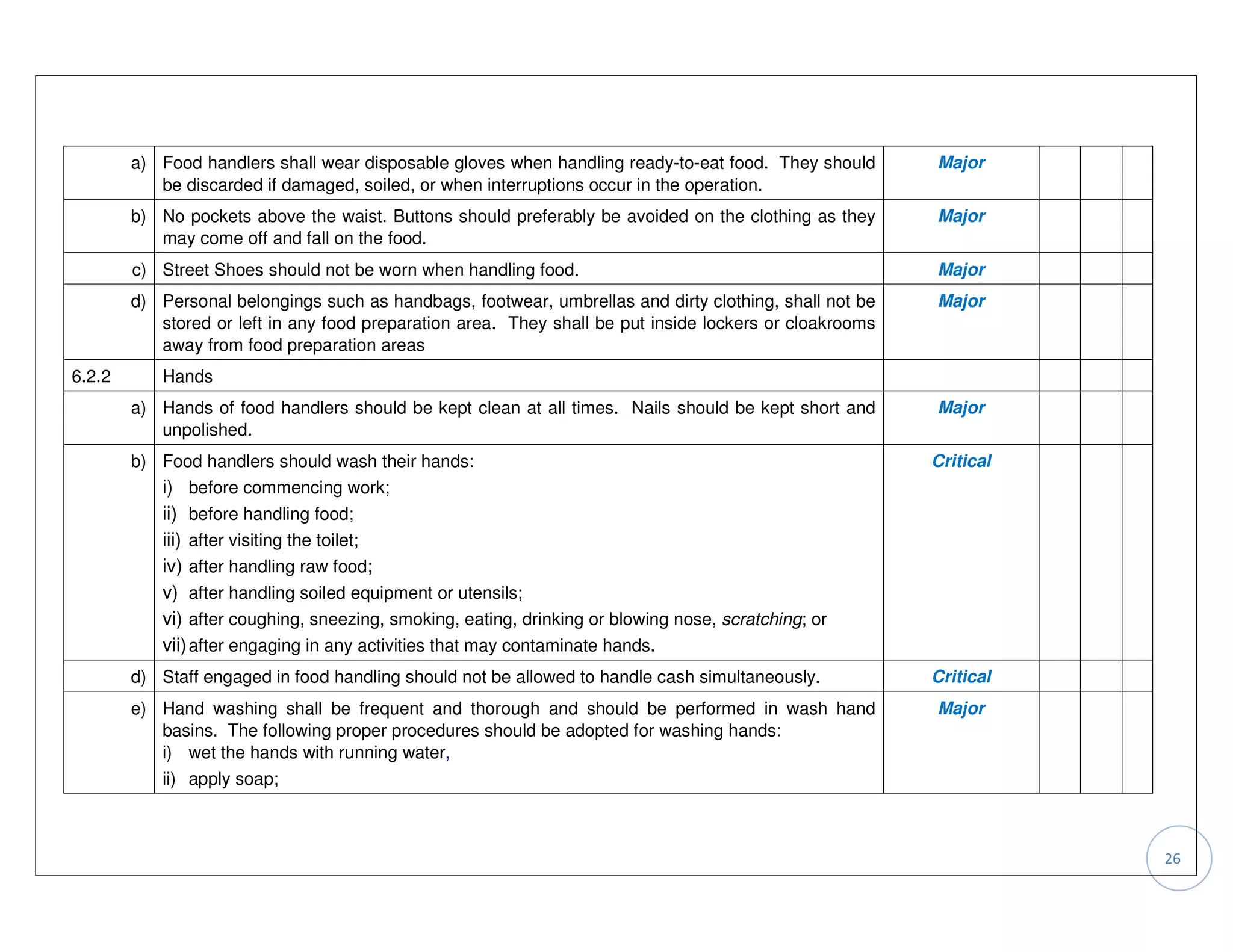

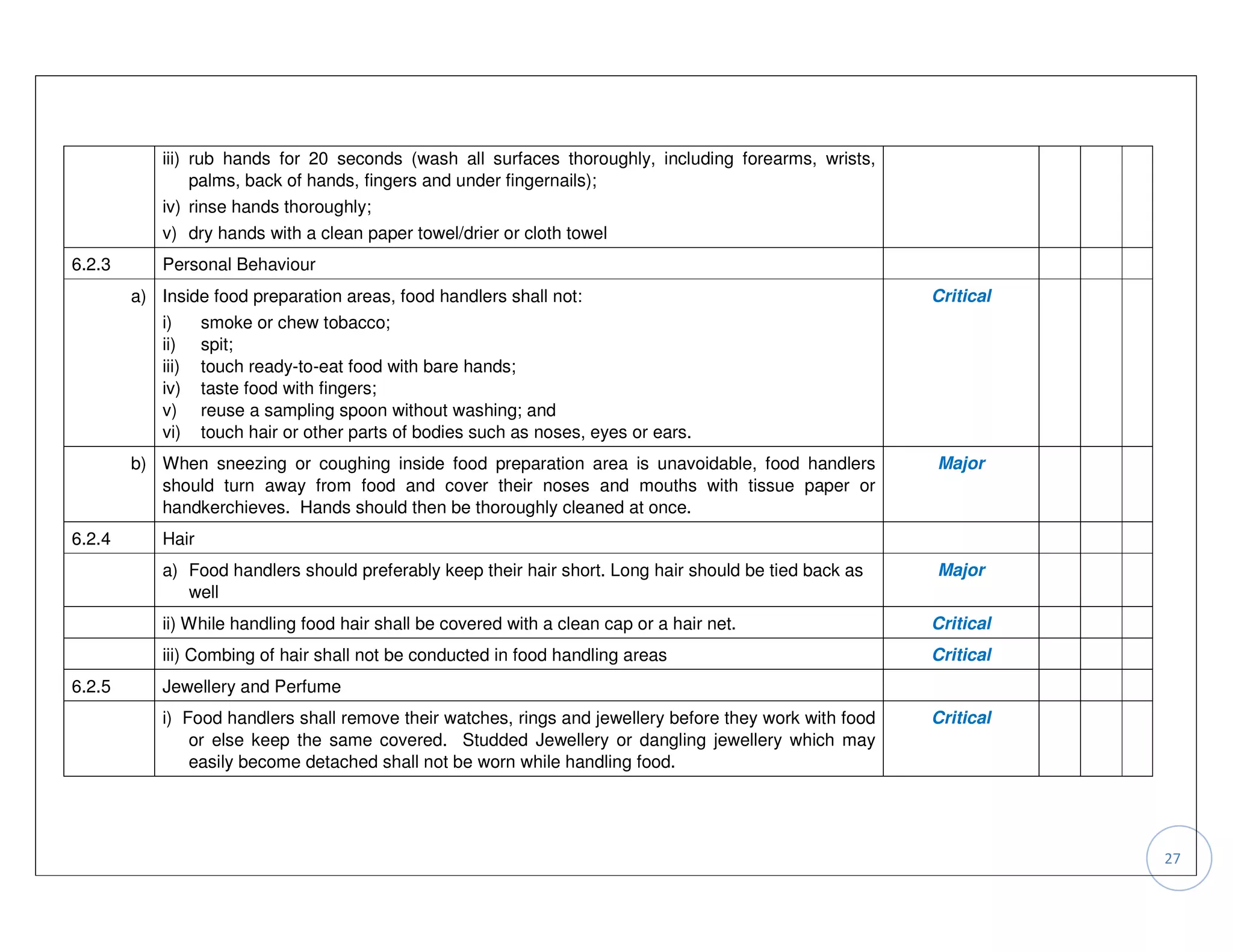

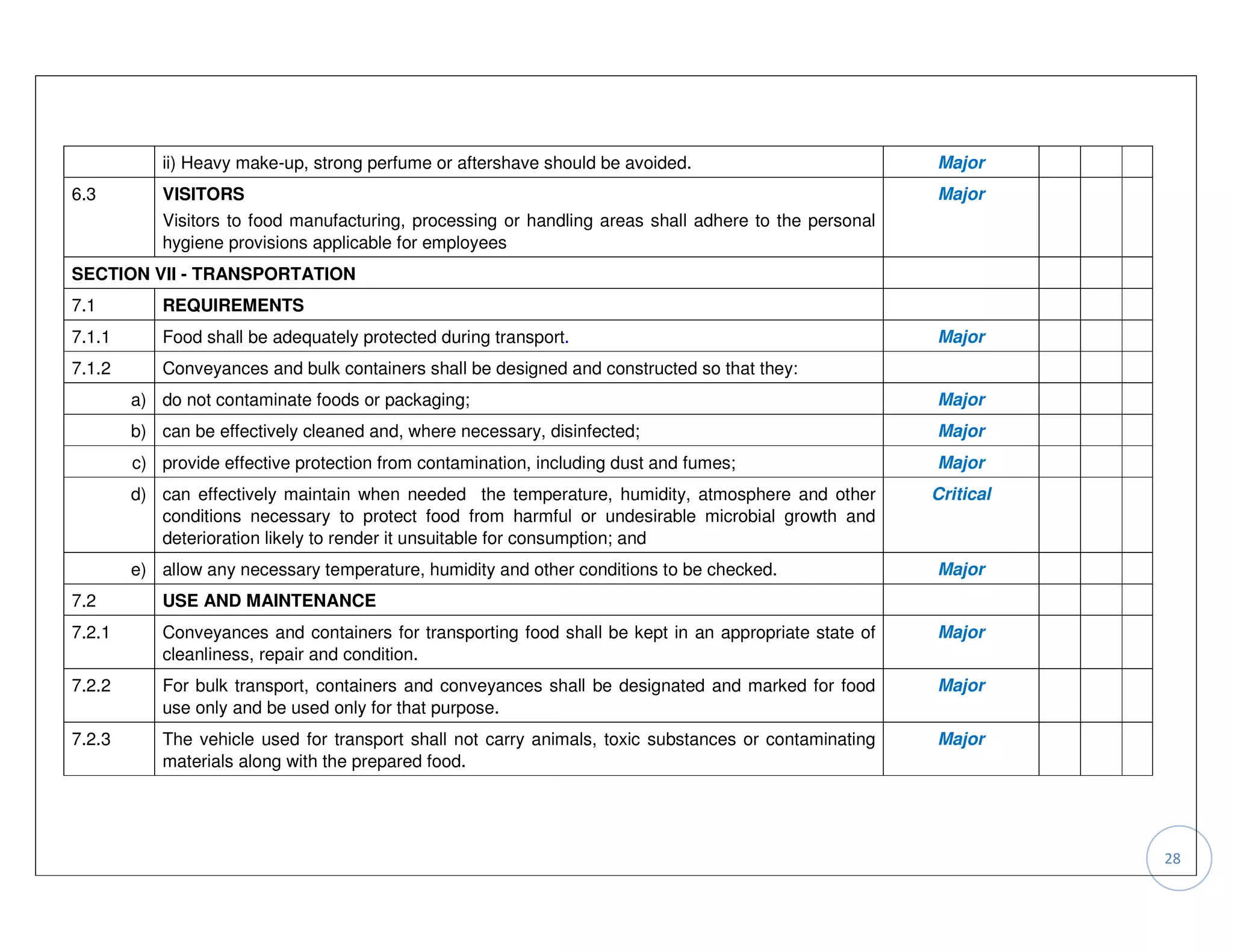

This document outlines criteria for auditing food establishments. It covers requirements in several areas:

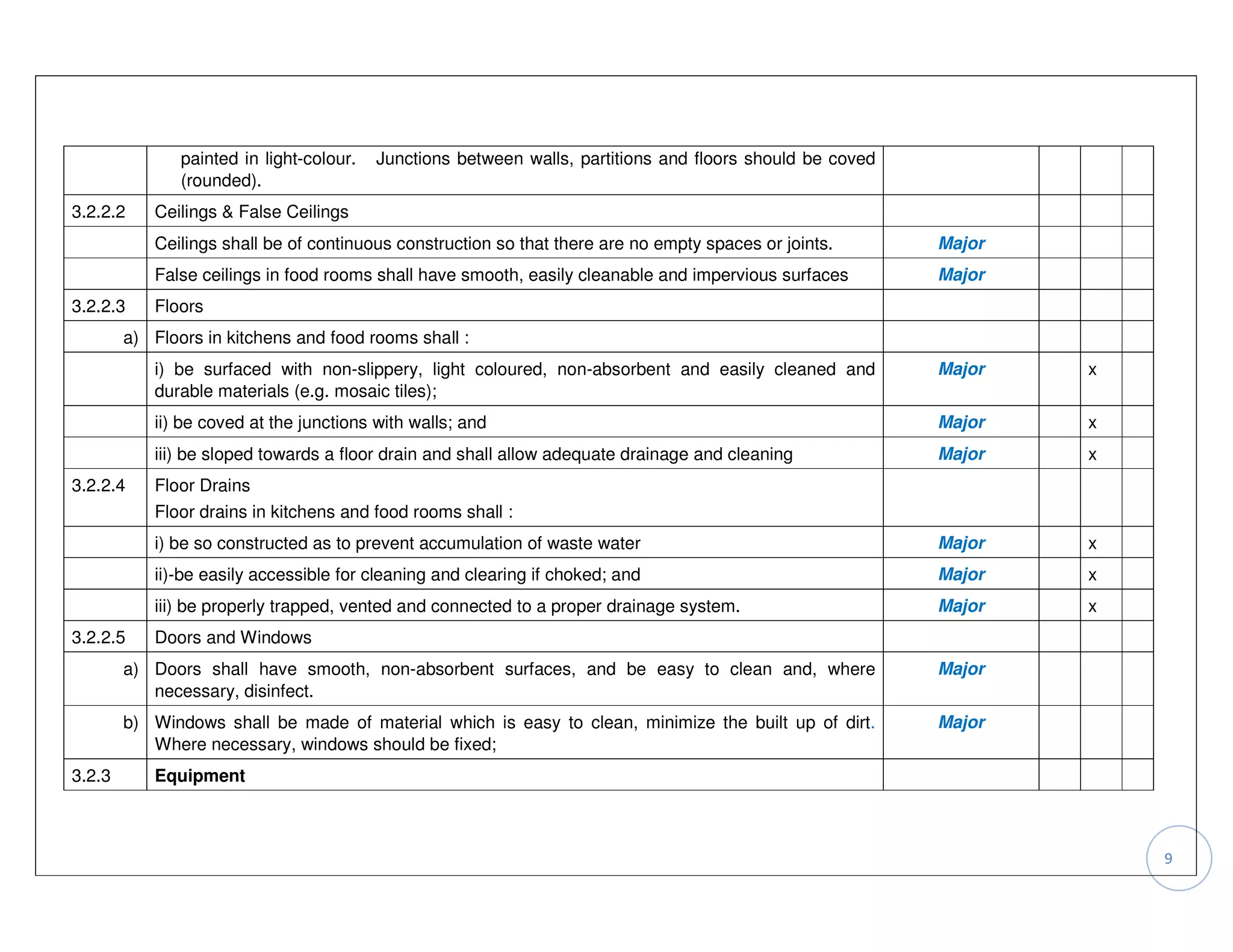

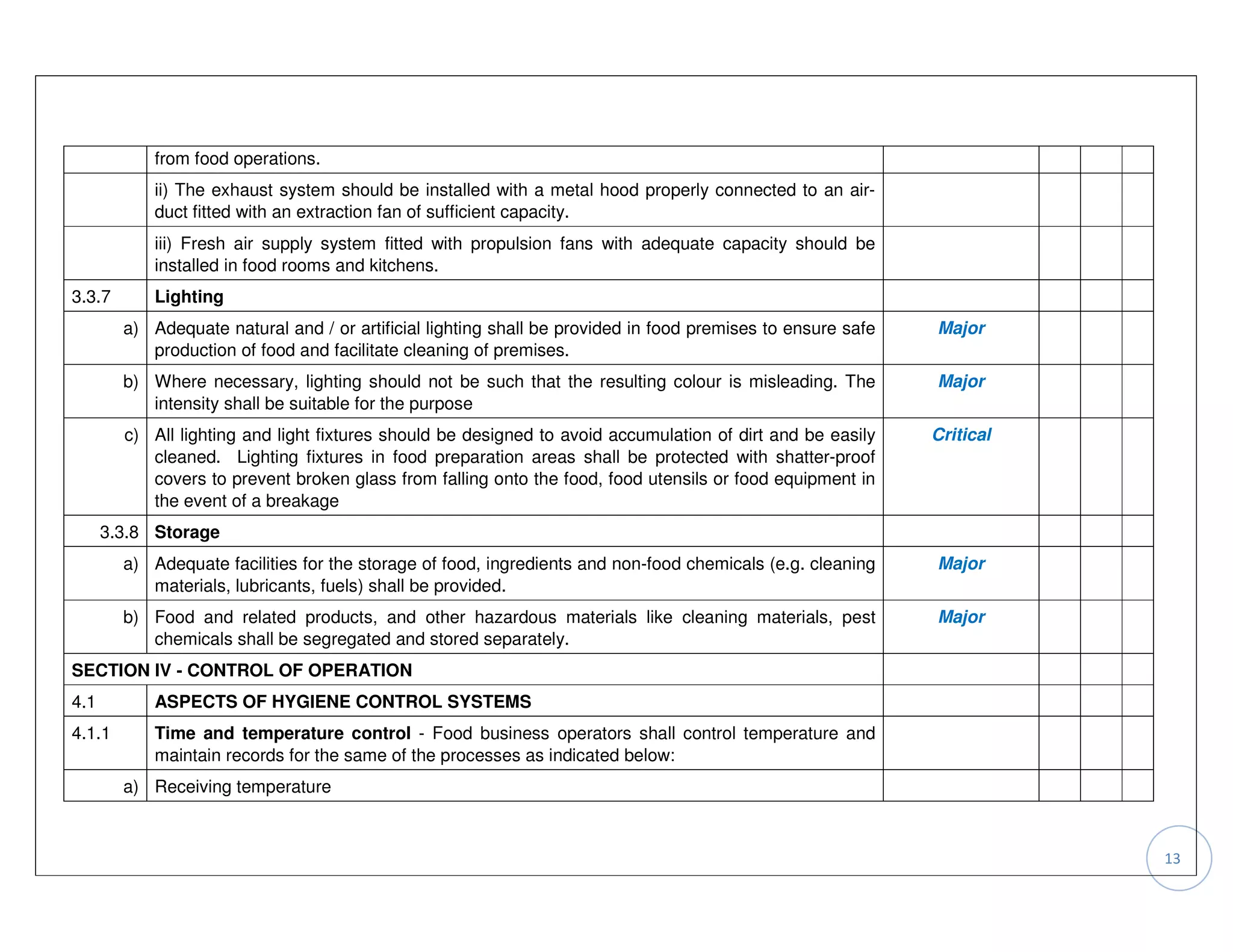

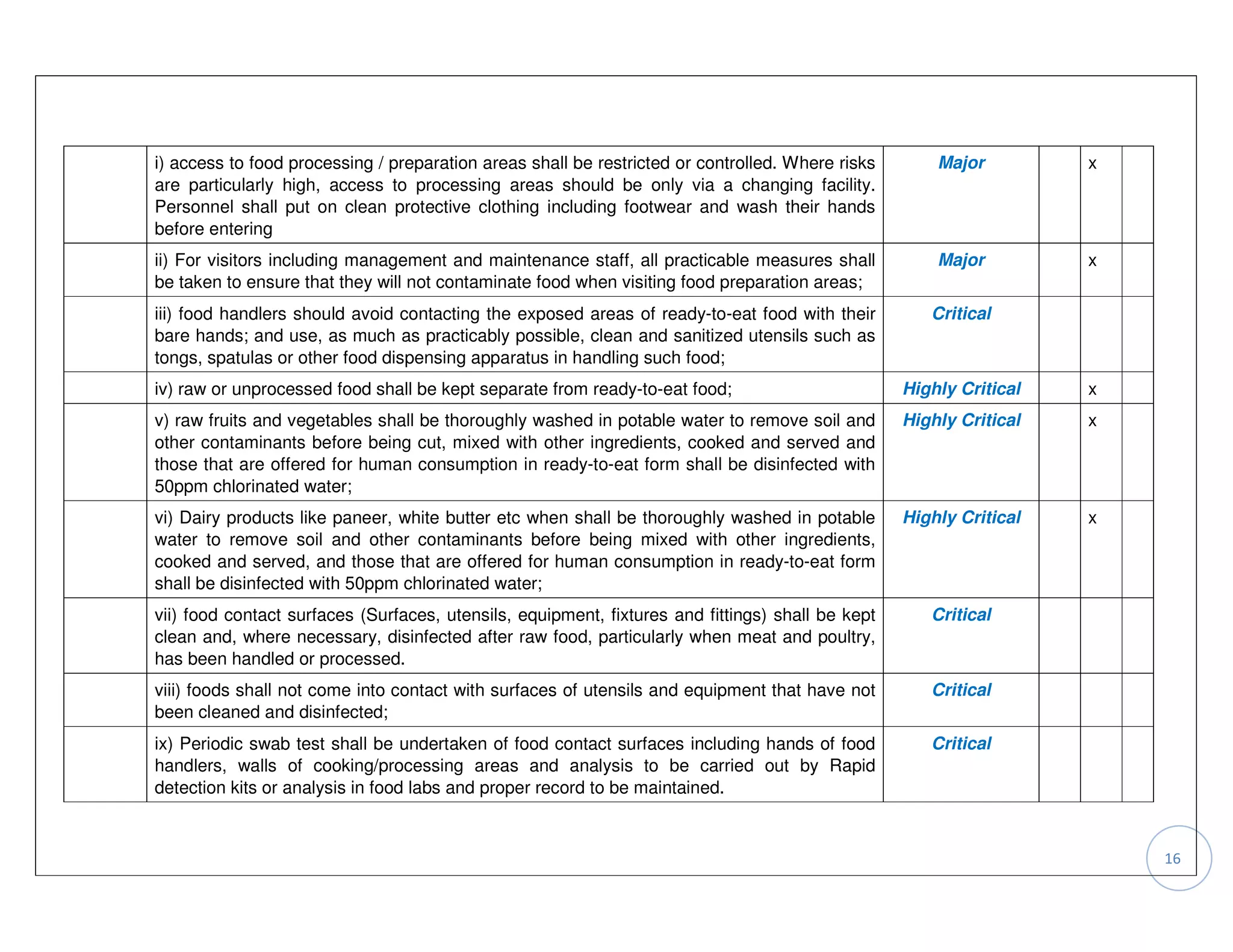

1. Location and premises/establishment design must meet food safety standards. This includes proper layout, ventilation, and separation of areas.

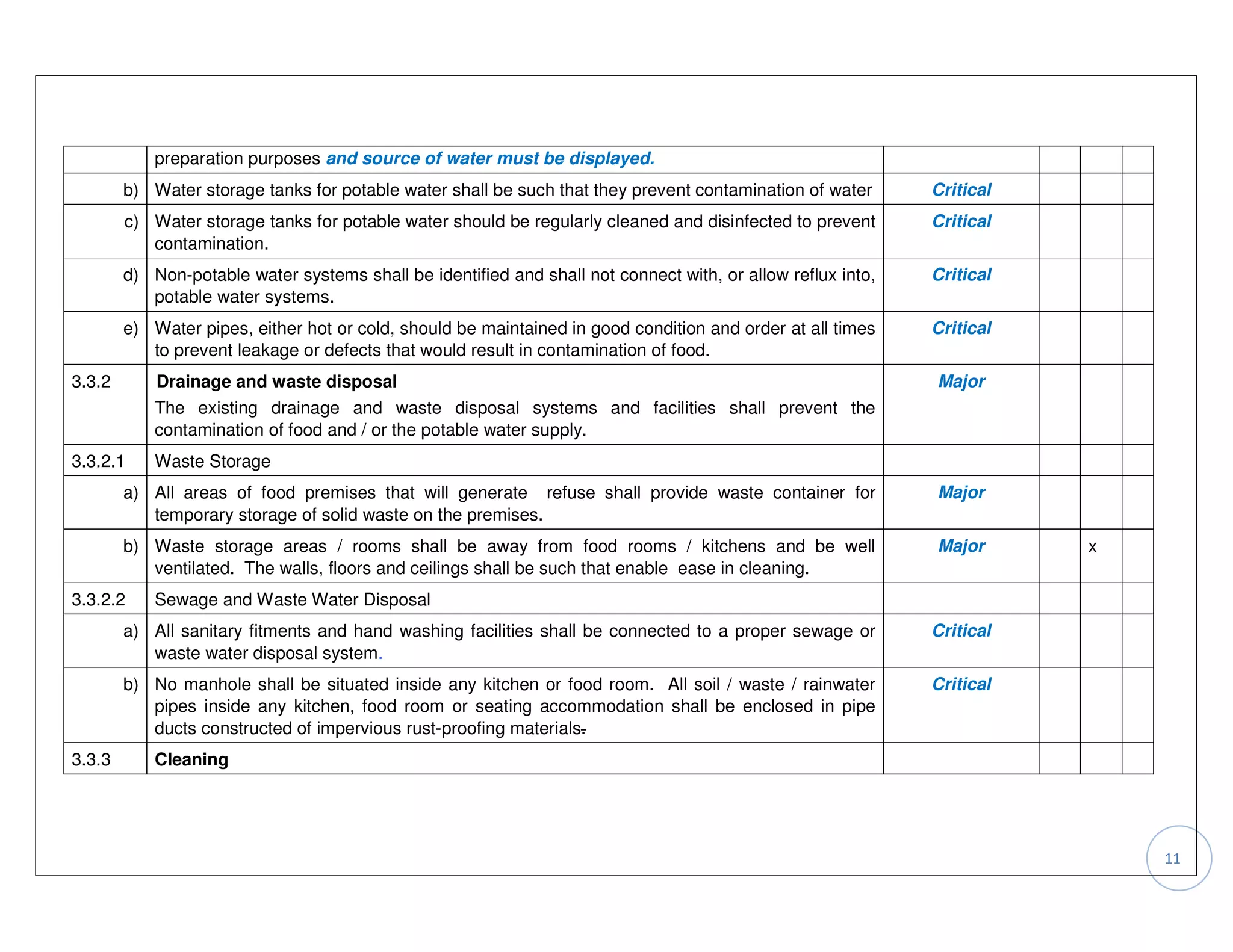

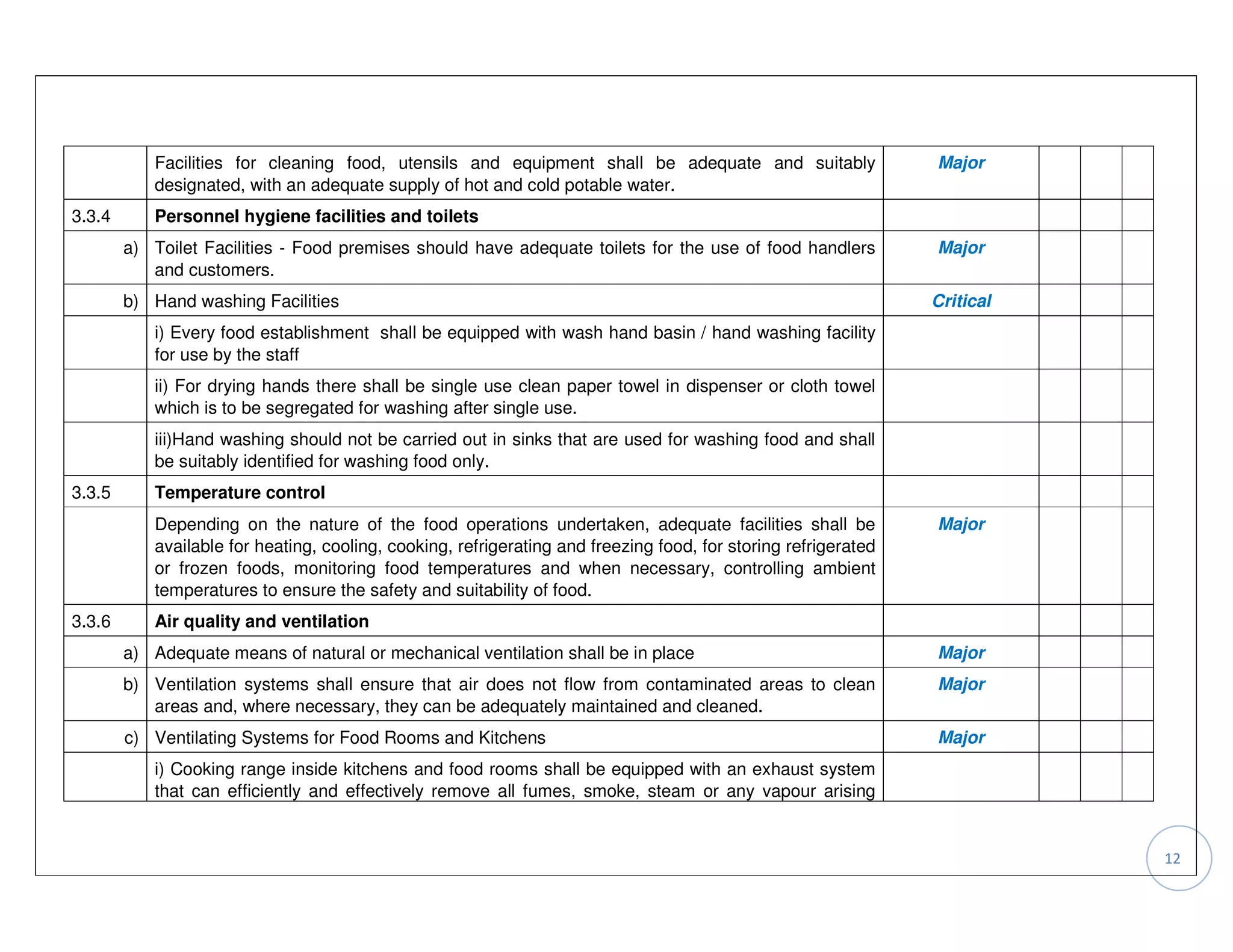

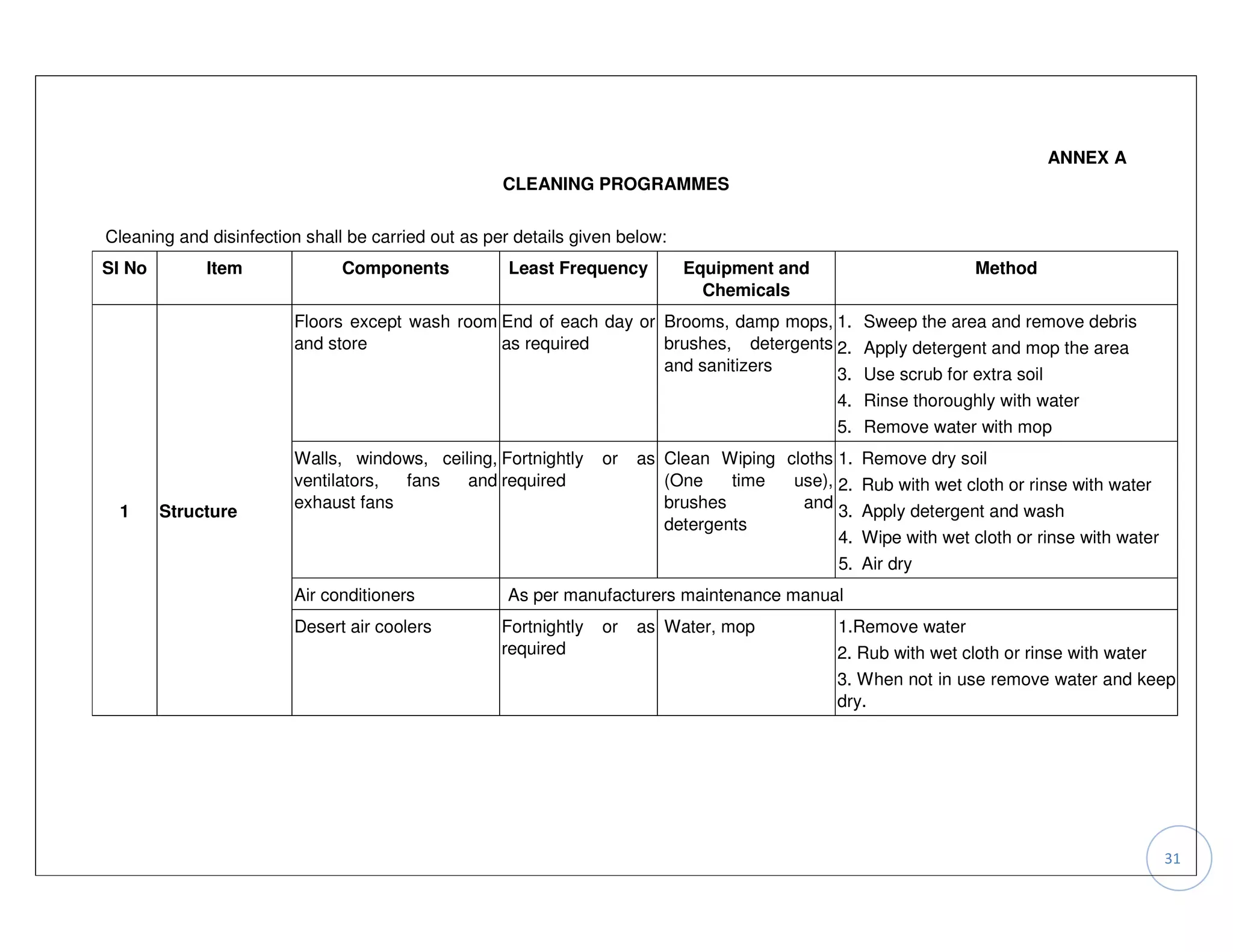

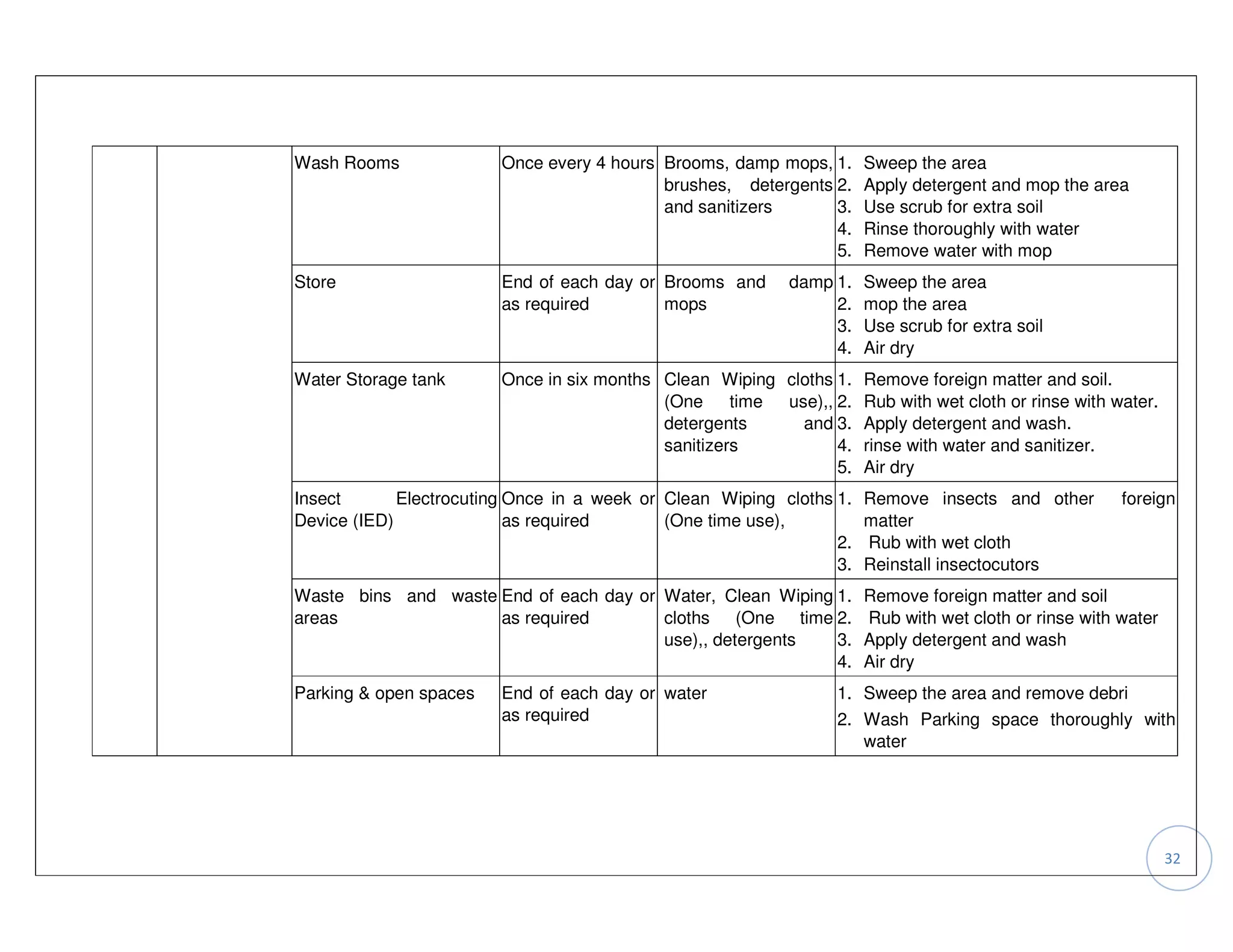

2. Facilities like water supply, drainage, waste disposal, cleaning areas, and handwashing must be adequate and prevent contamination.

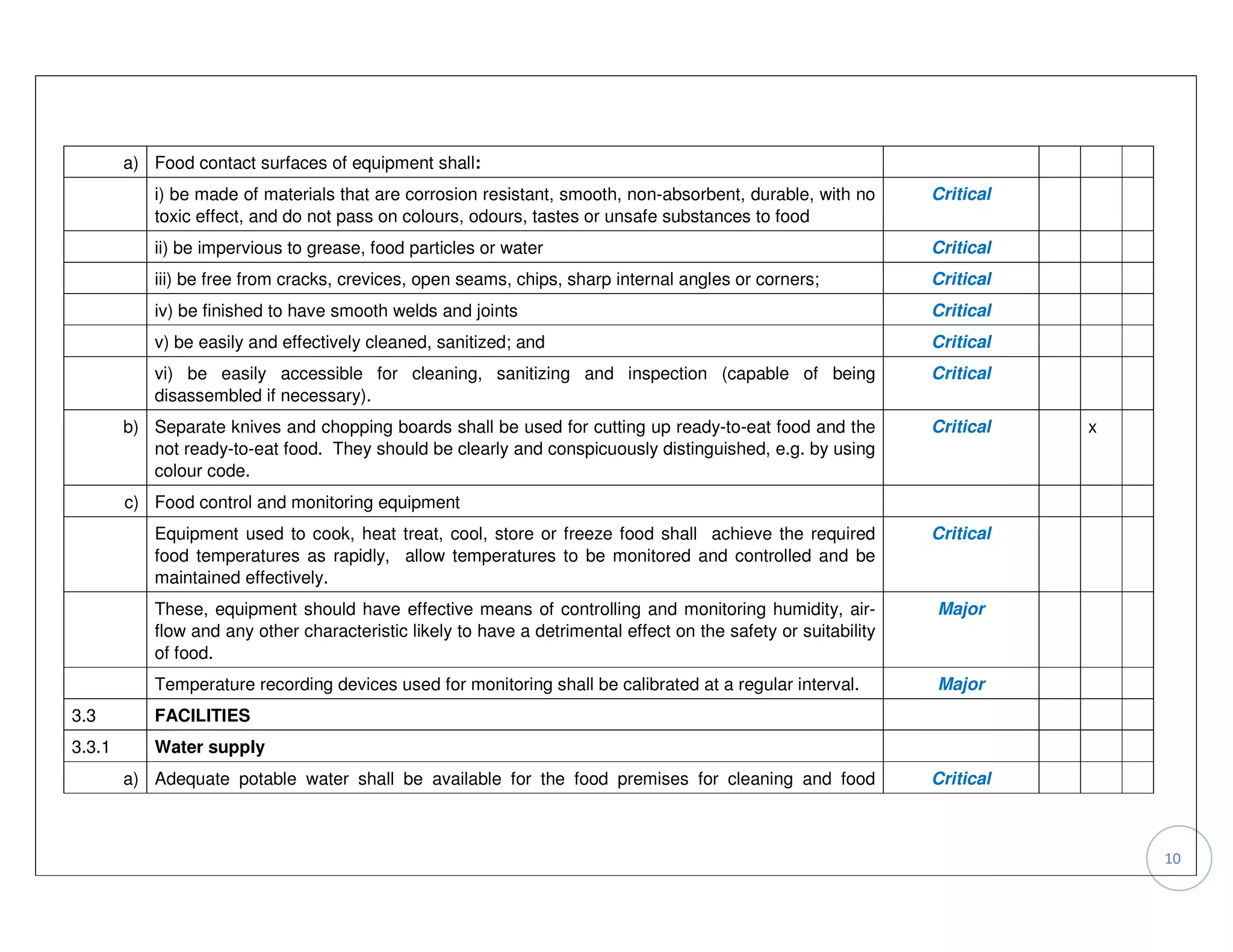

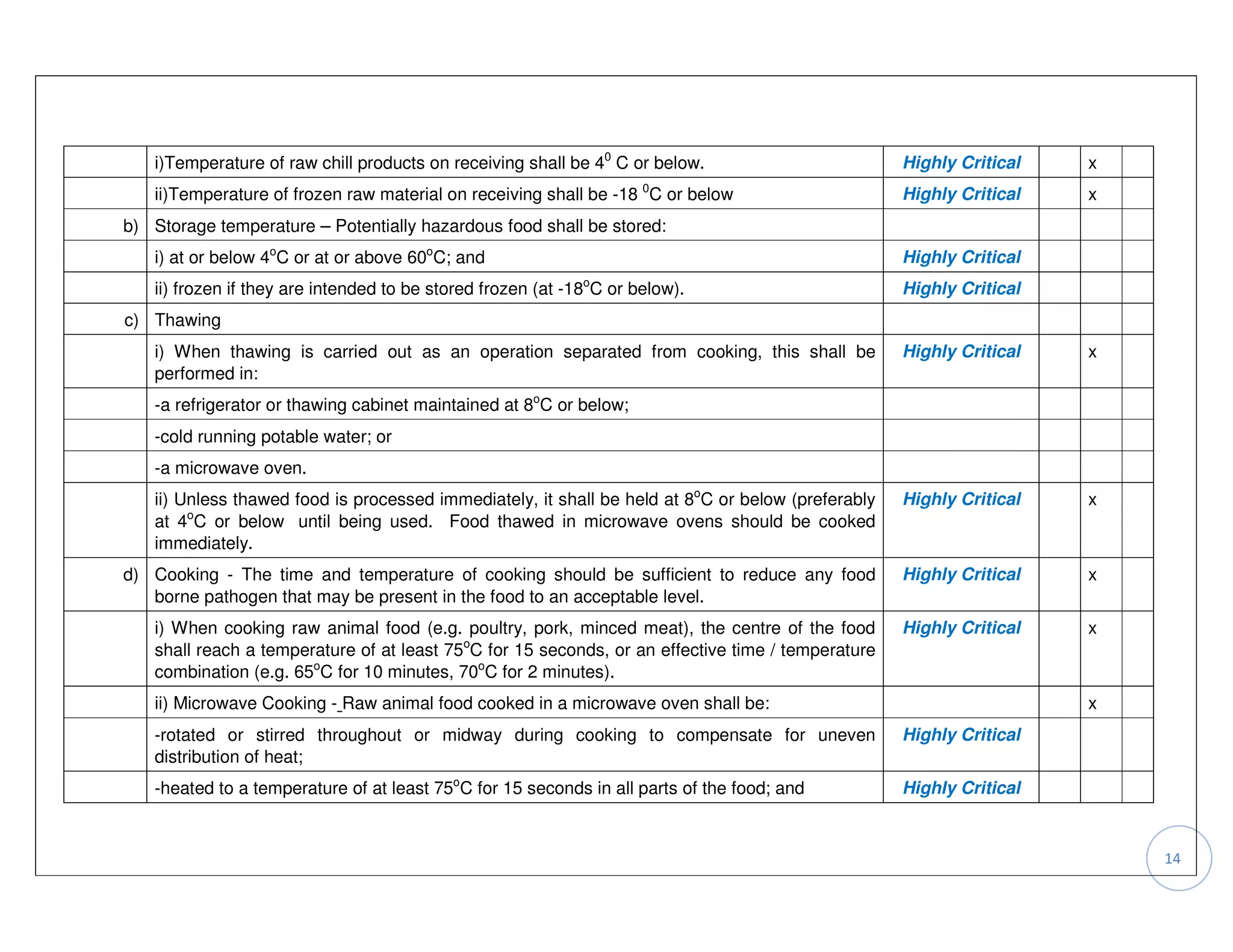

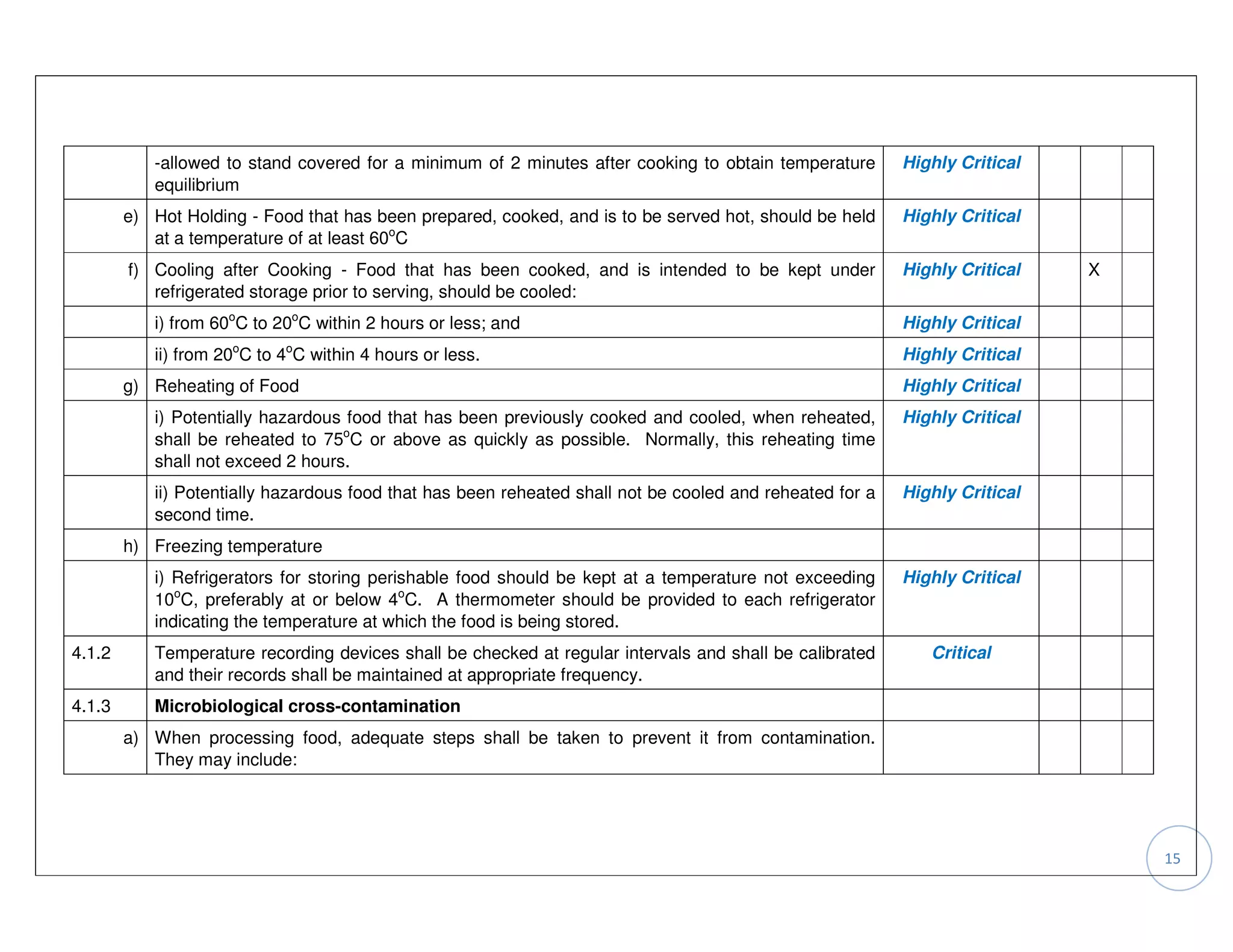

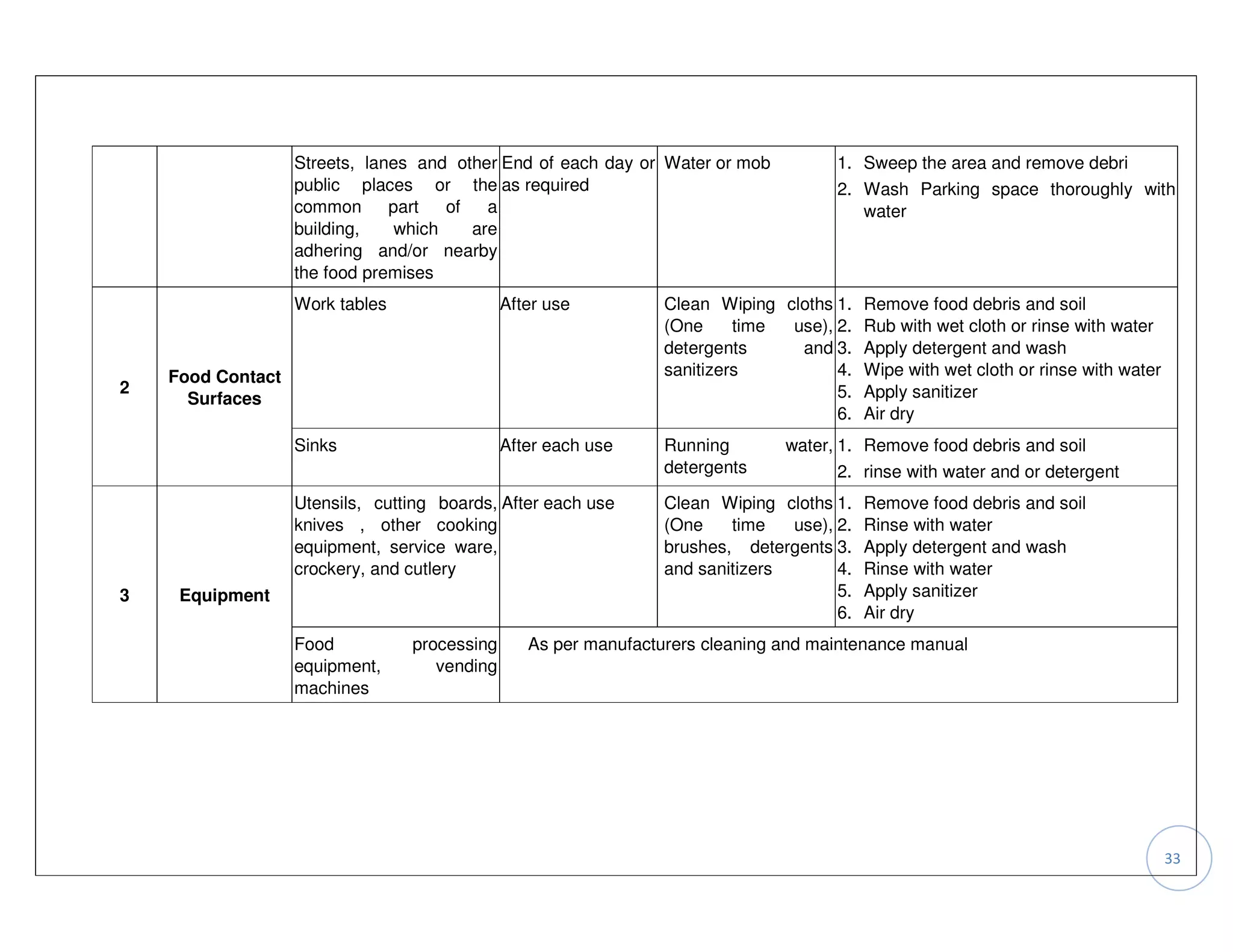

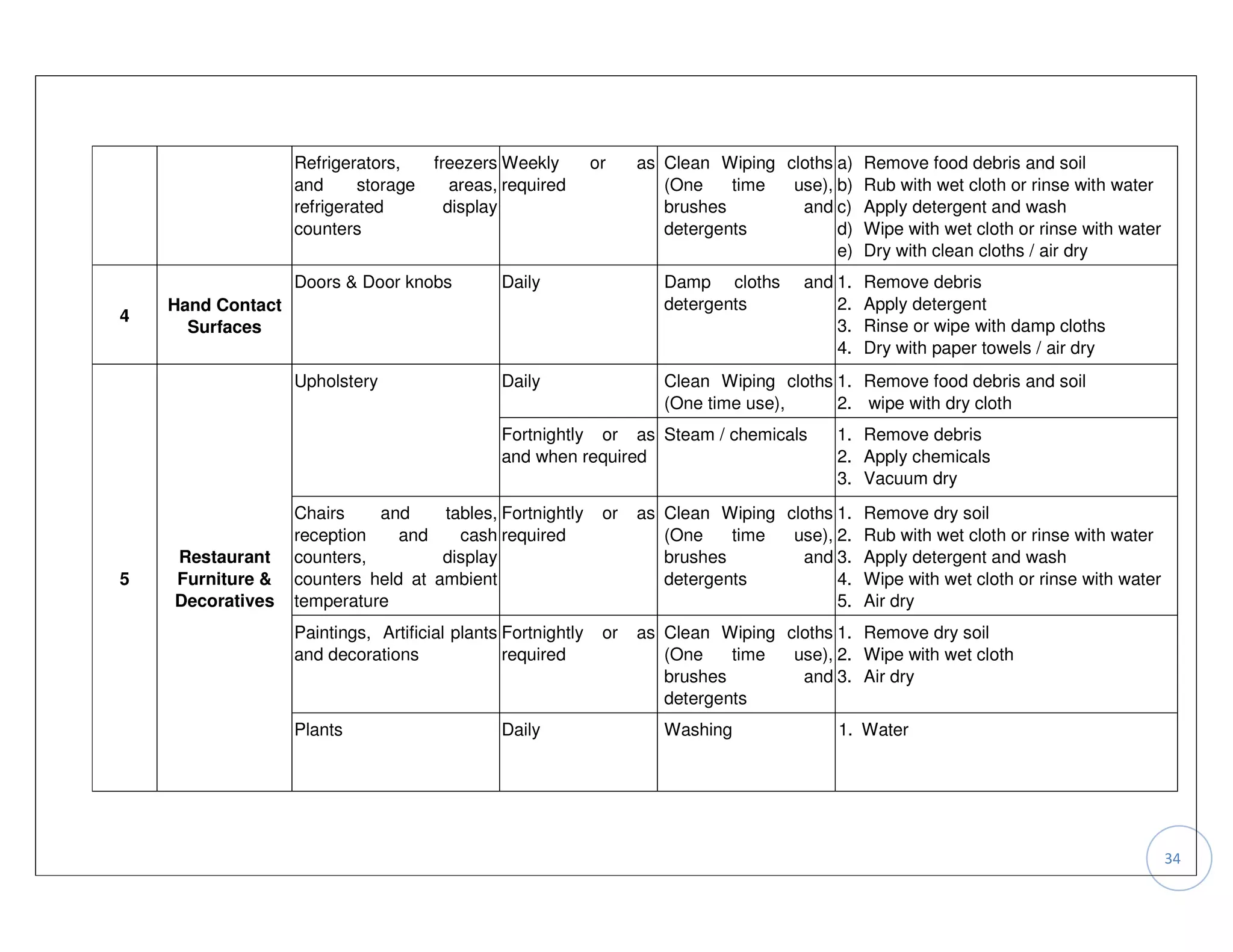

3. Equipment and surfaces must be made of appropriate materials to enable cleaning and maintenance of hygiene. Temperature control is also required.

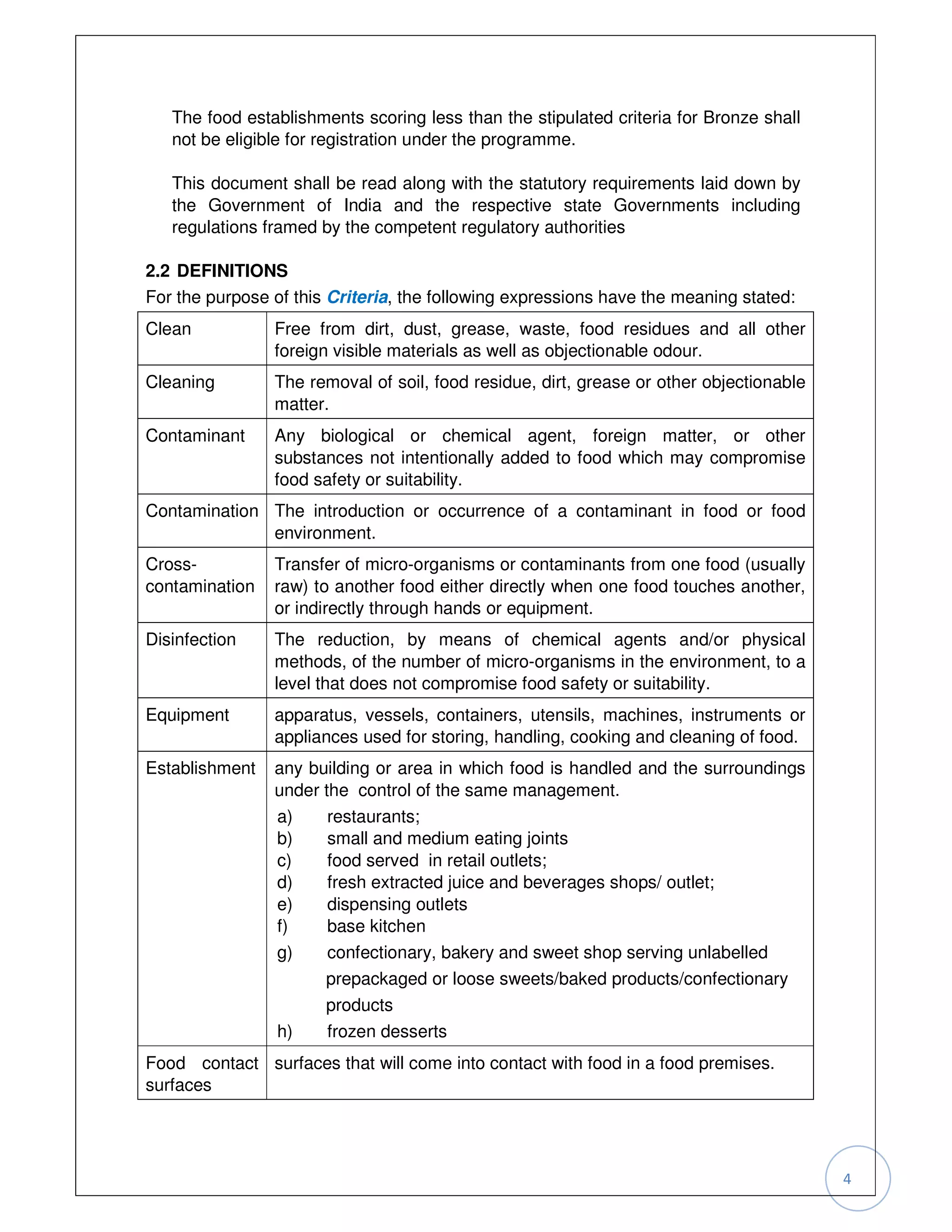

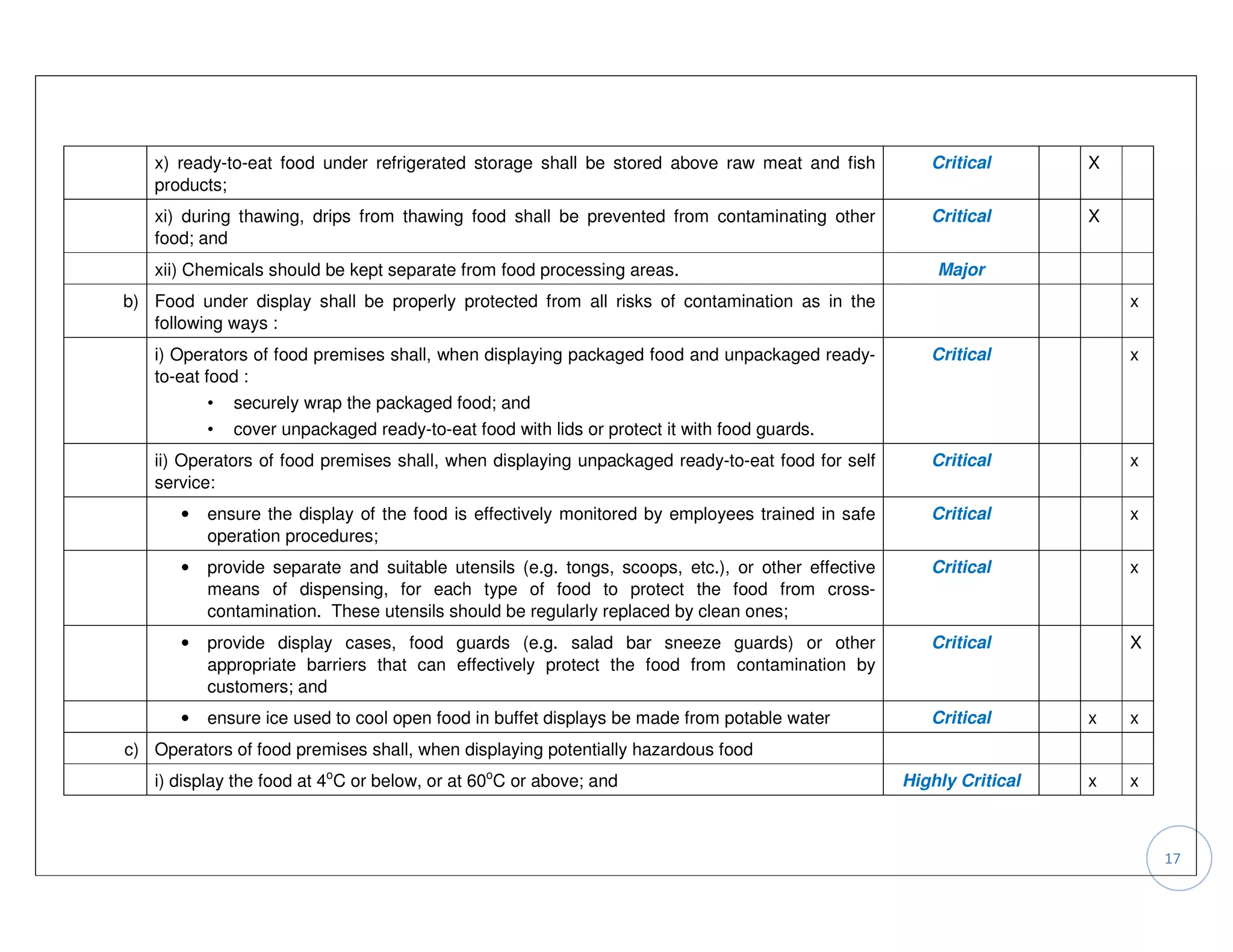

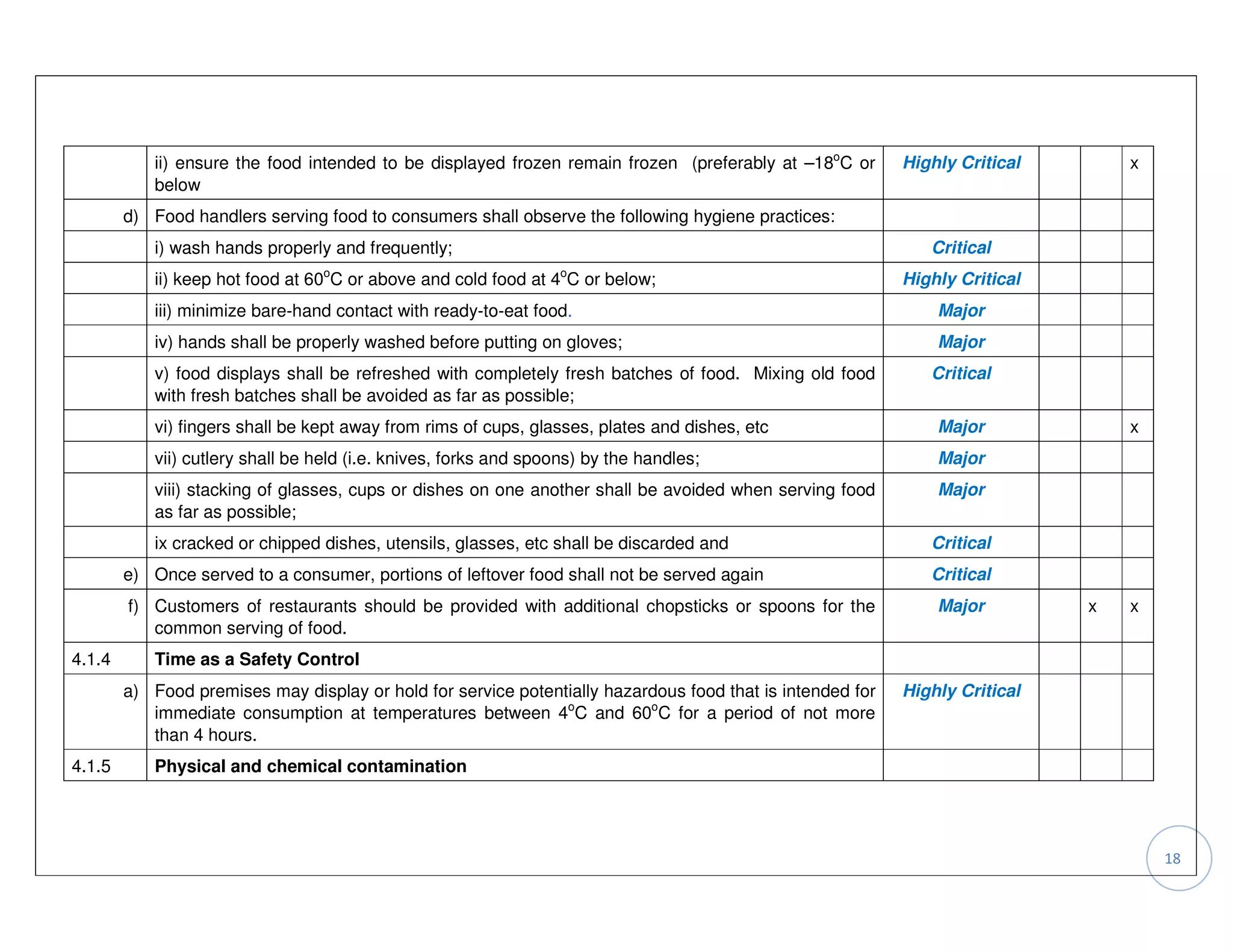

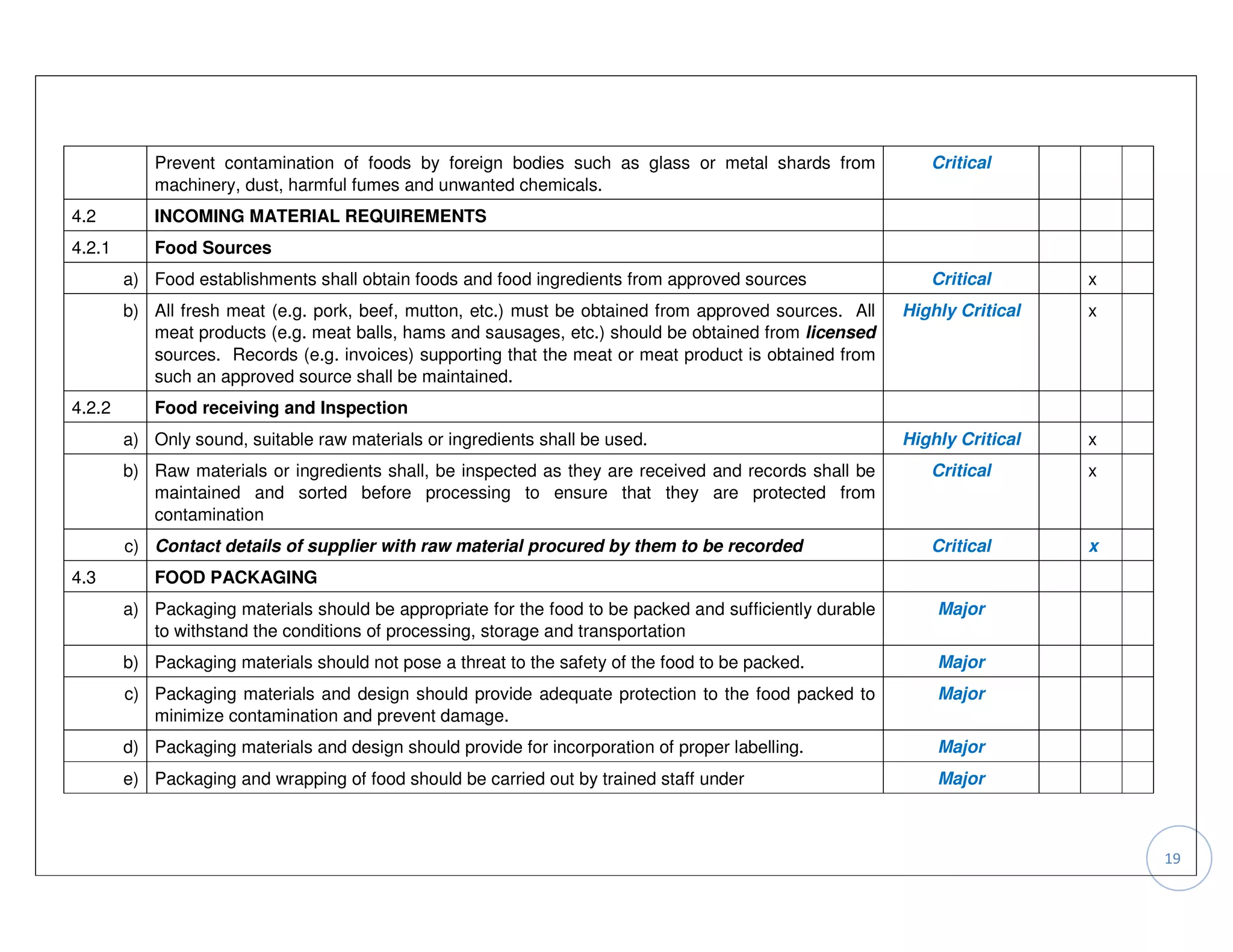

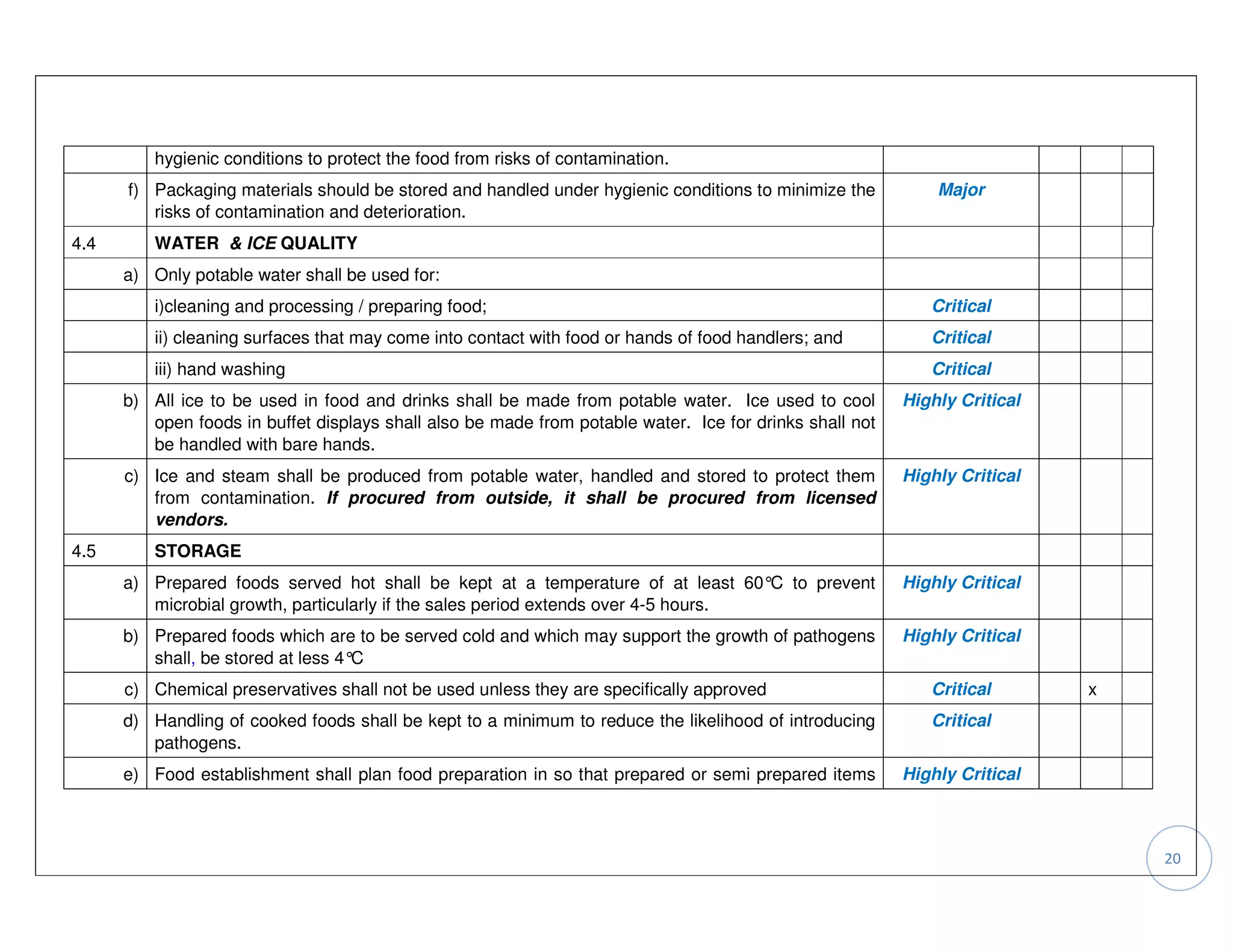

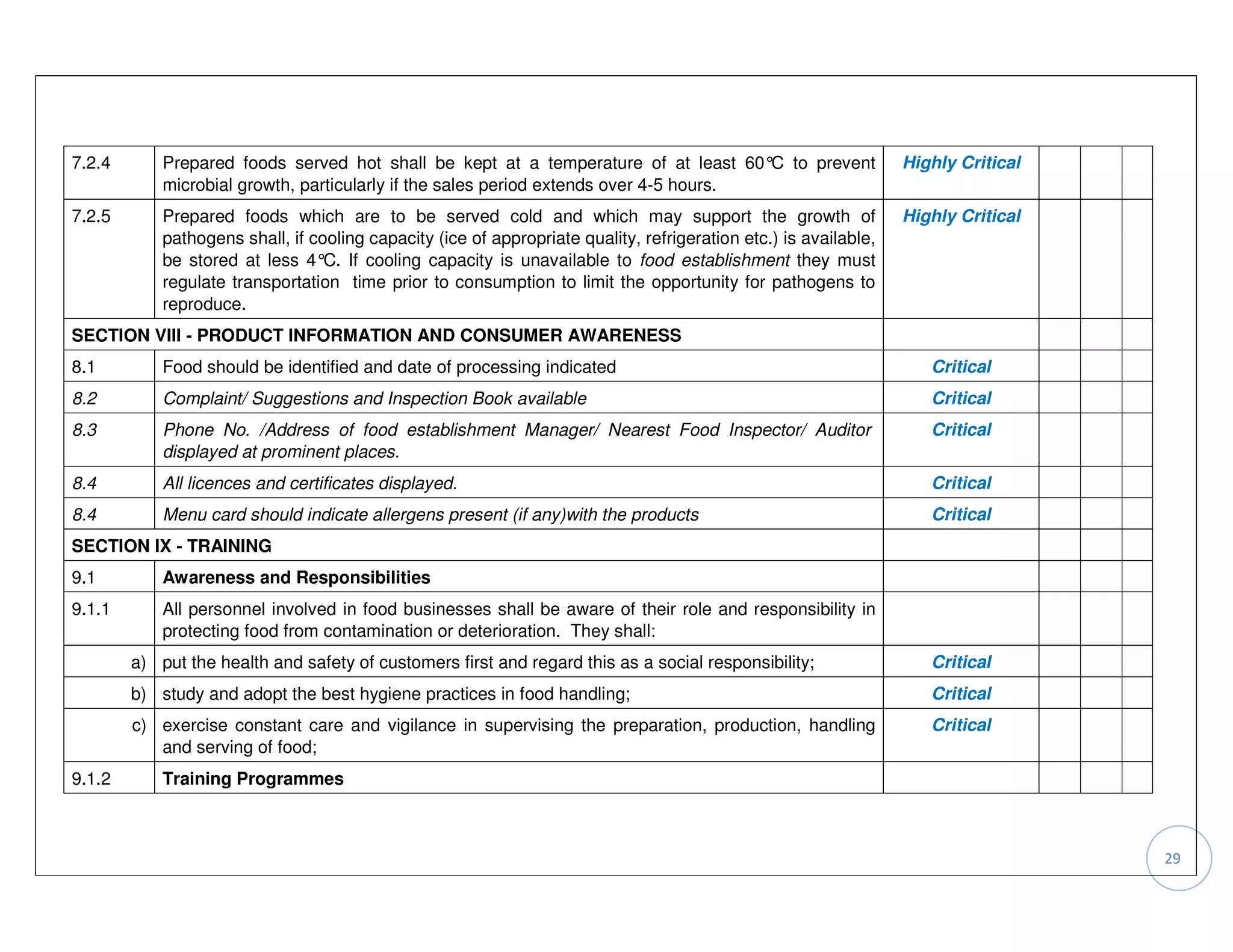

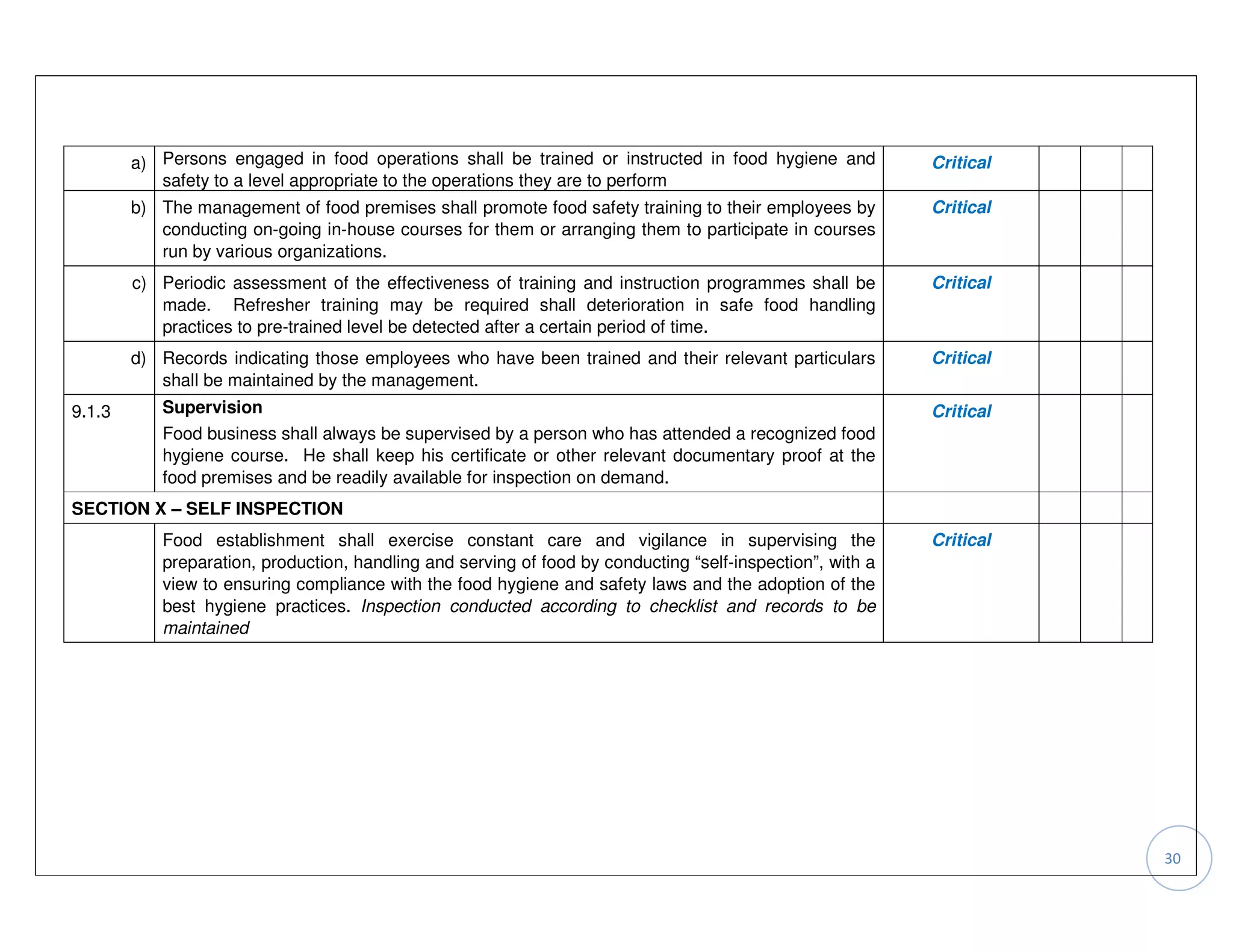

The criteria categorizes requirements as highly critical, critical or major and establishes compliance levels for ratings of platinum, gold, silver or bronze. Proper implementation of food safety practices is the overall goal.