This document provides an overview of Delta Connection's in-flight WiFi program for certain CRJ aircraft. Key points include:

1) Installation of WiFi systems began last year on a prototype CRJ700 aircraft and flight testing was completed in August.

2) Production installations are taking place over several months at maintenance bases, with an goal of completing the Delta Connection fleet by November.

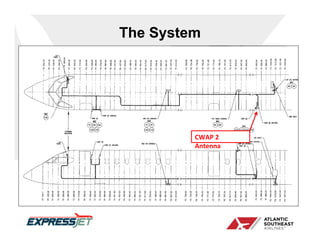

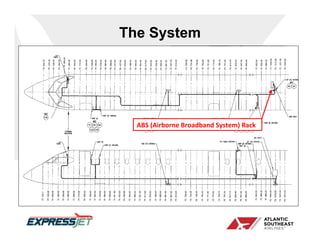

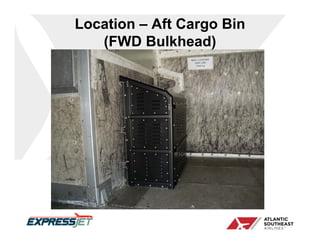

3) The WiFi system includes several components like access points, antennas, and a rack-mounted server located in the aircraft cabin and tail.

4) Operational impacts are minor, including a slight shift in center of gravity and reduced maximum weight in the aft cargo area.