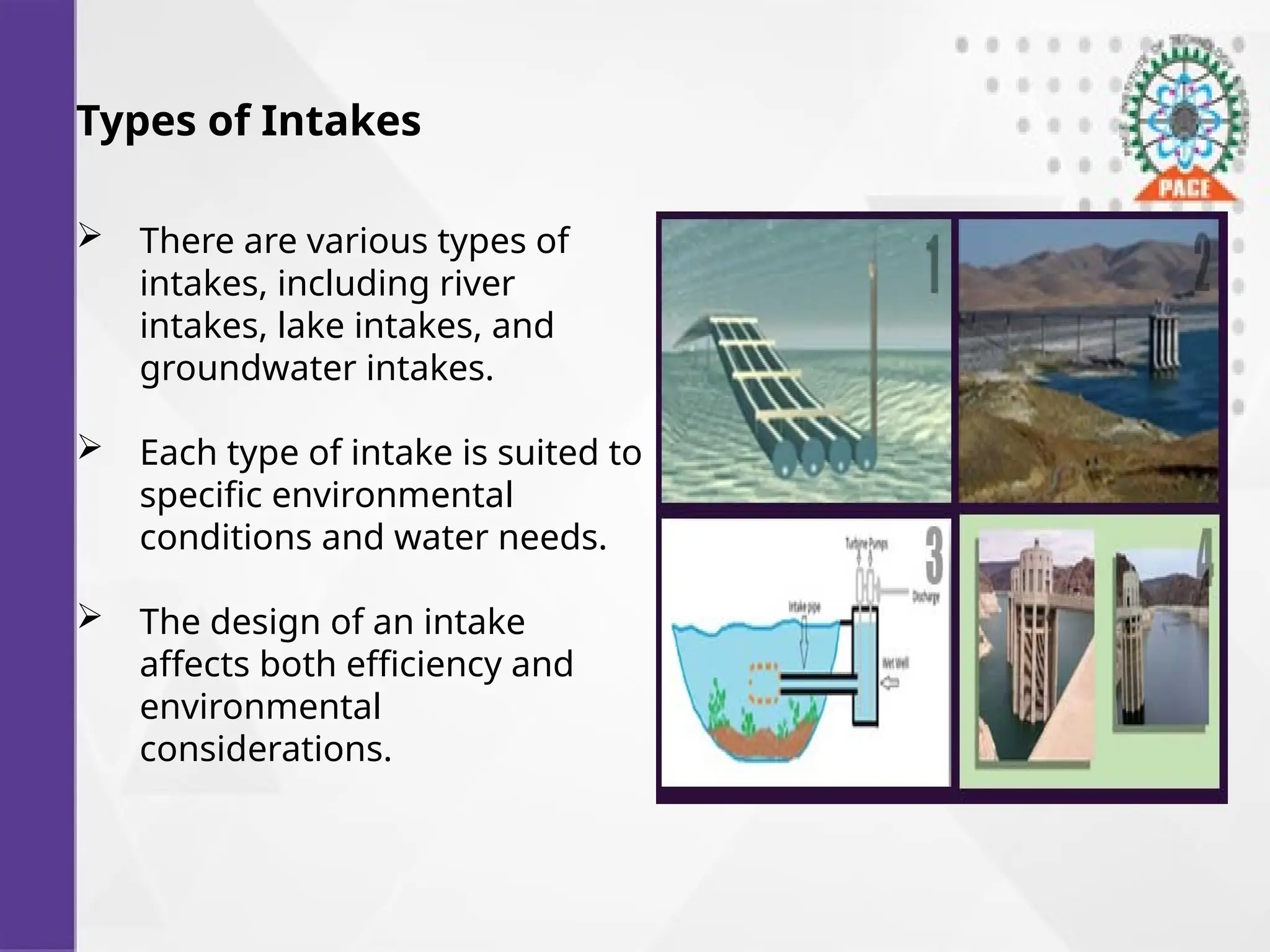

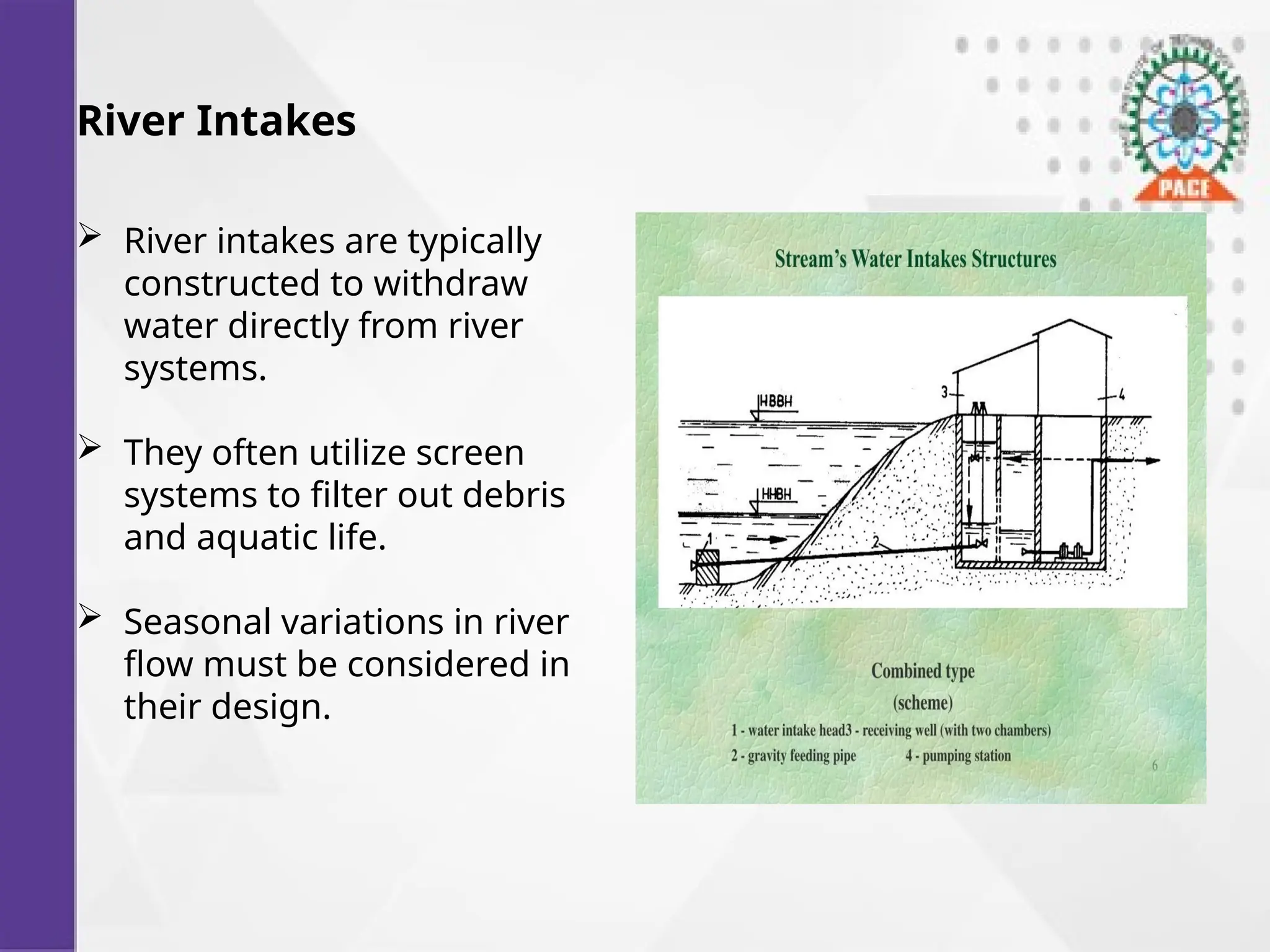

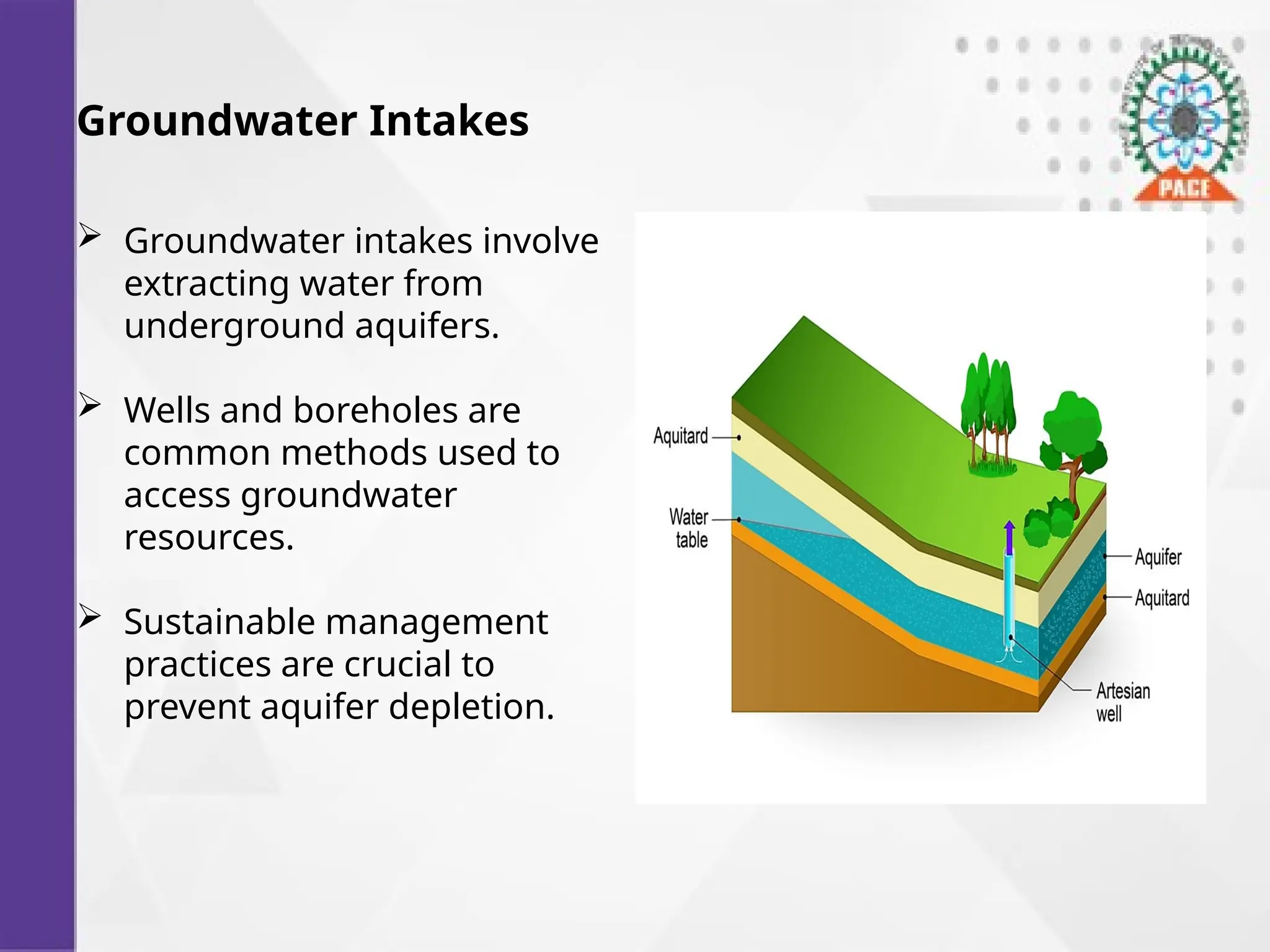

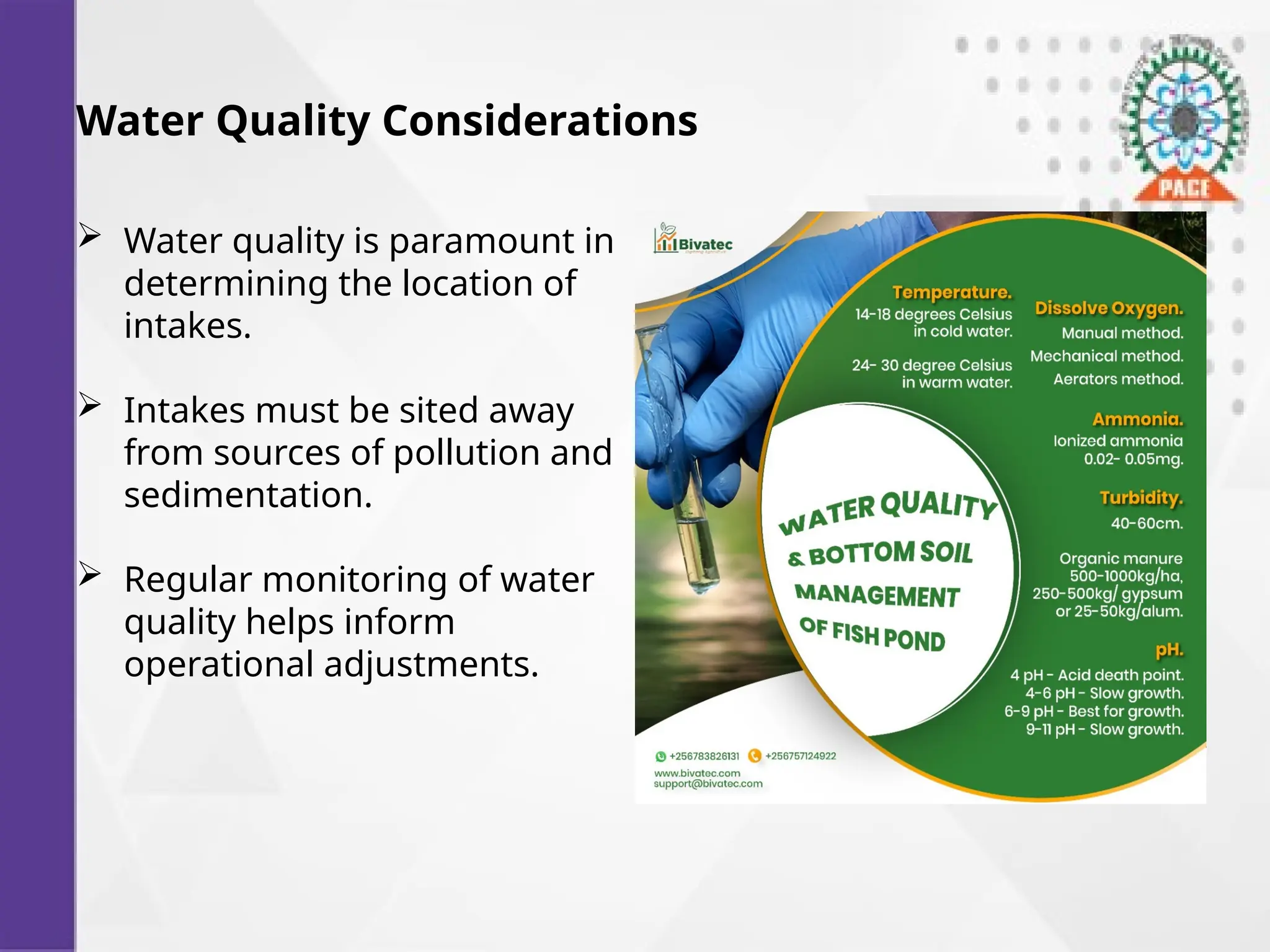

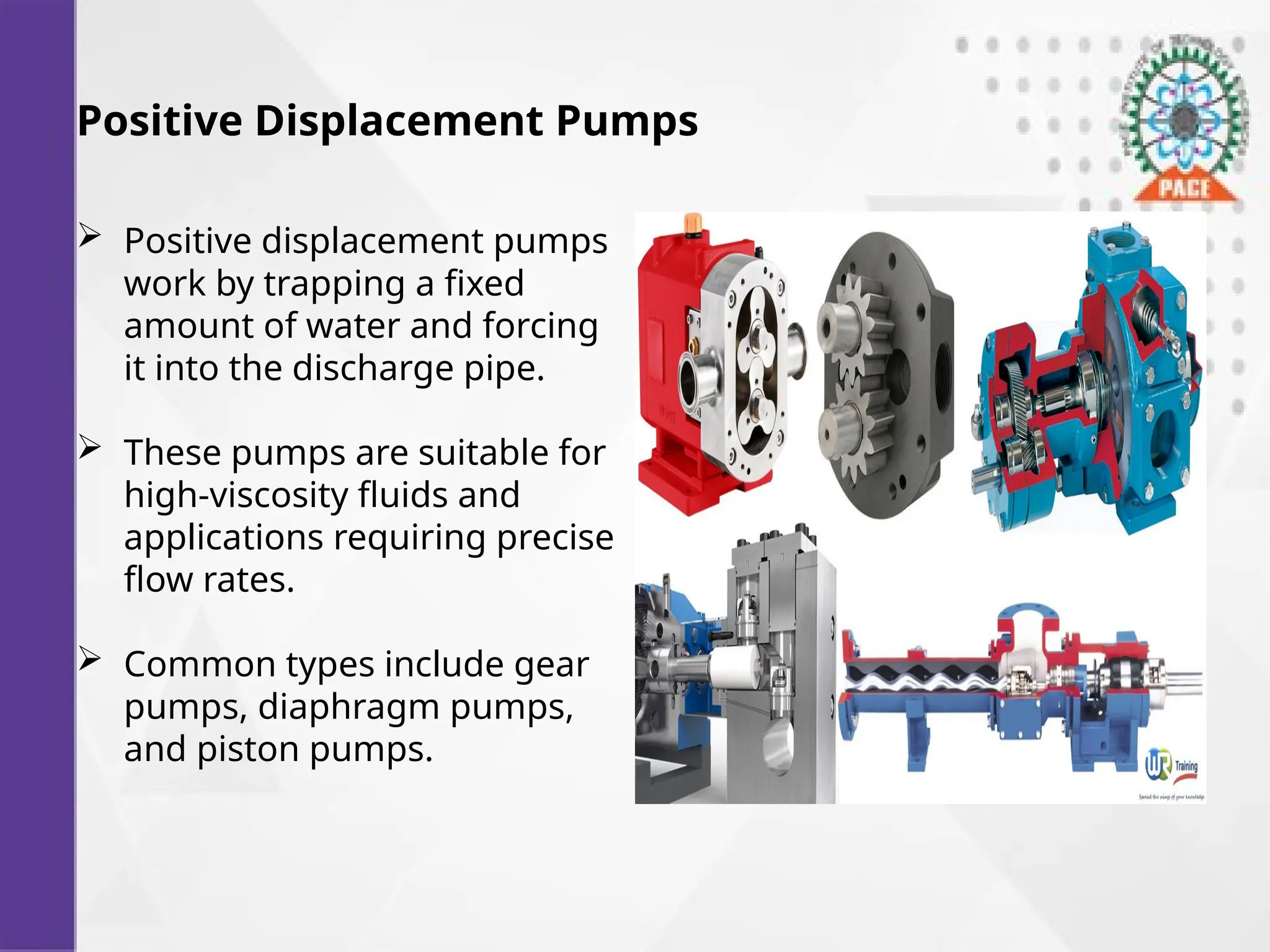

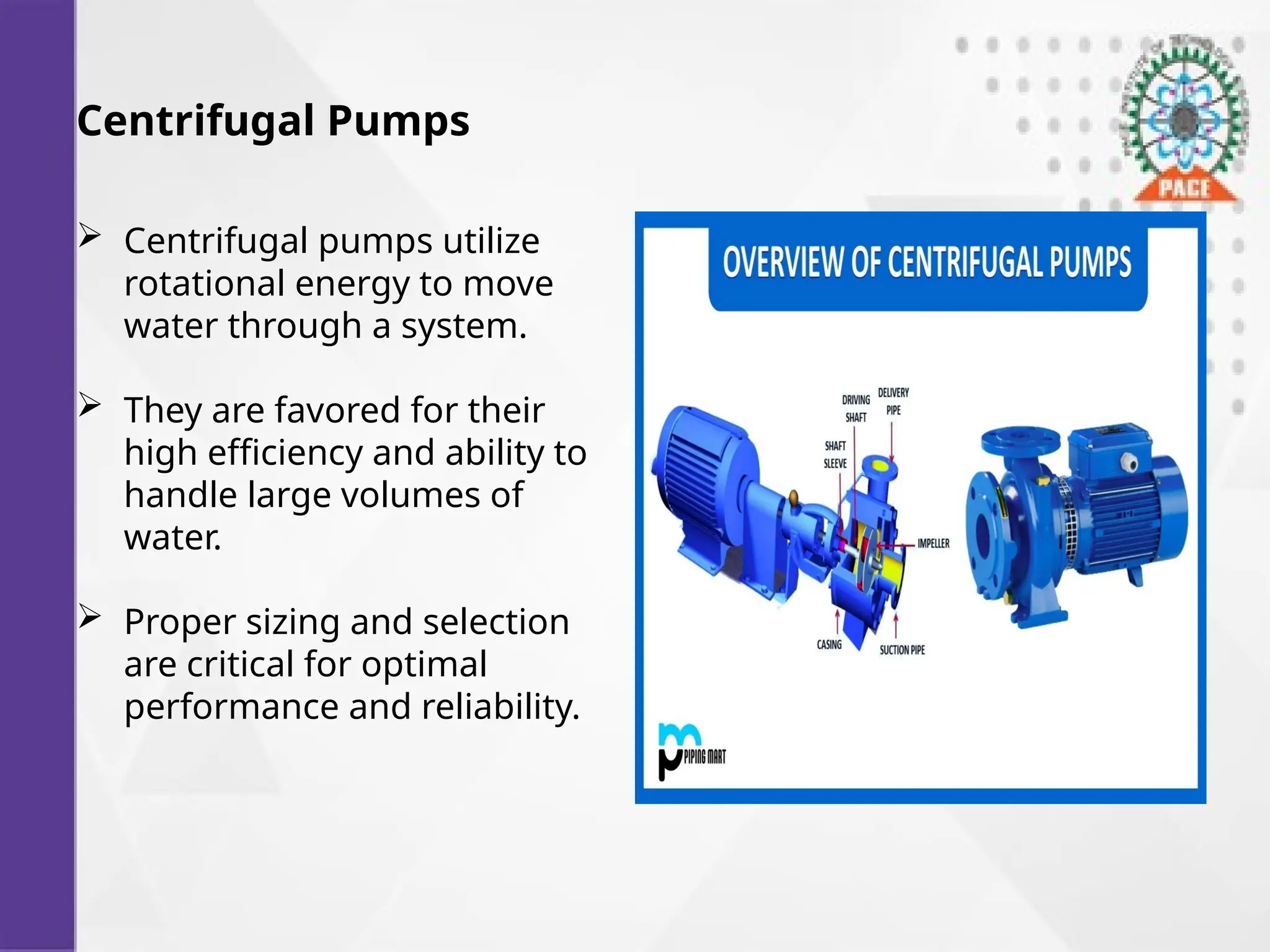

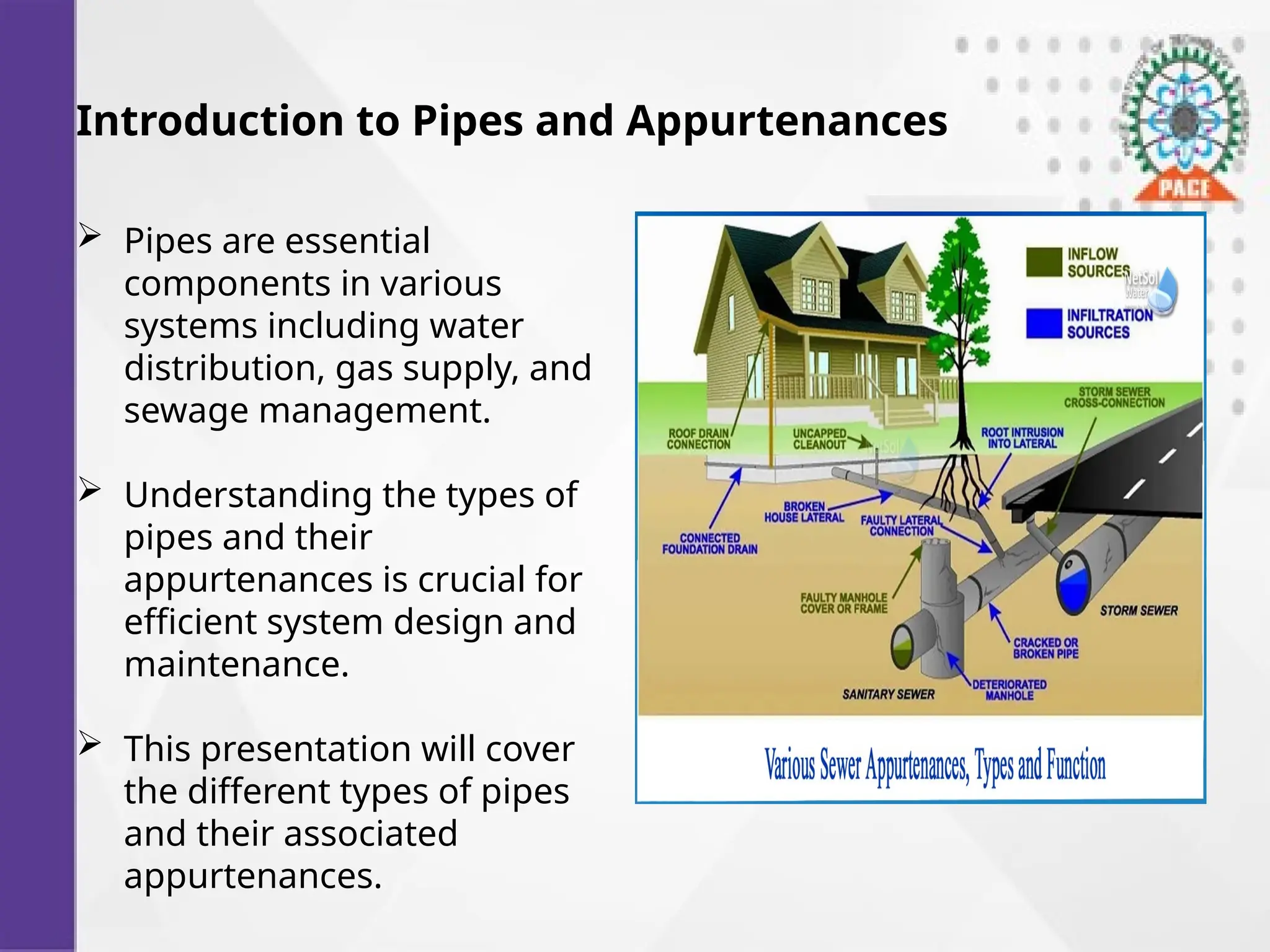

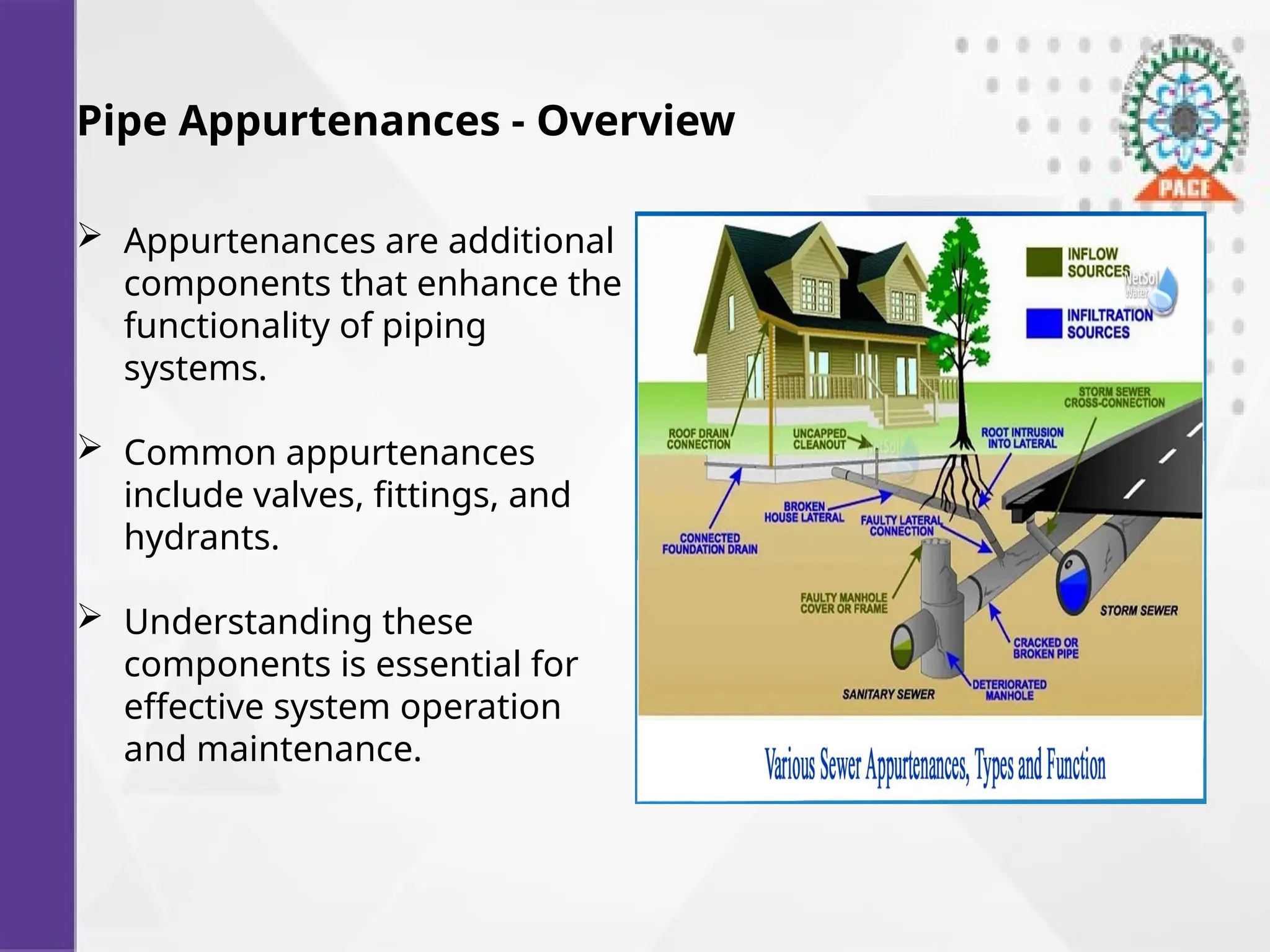

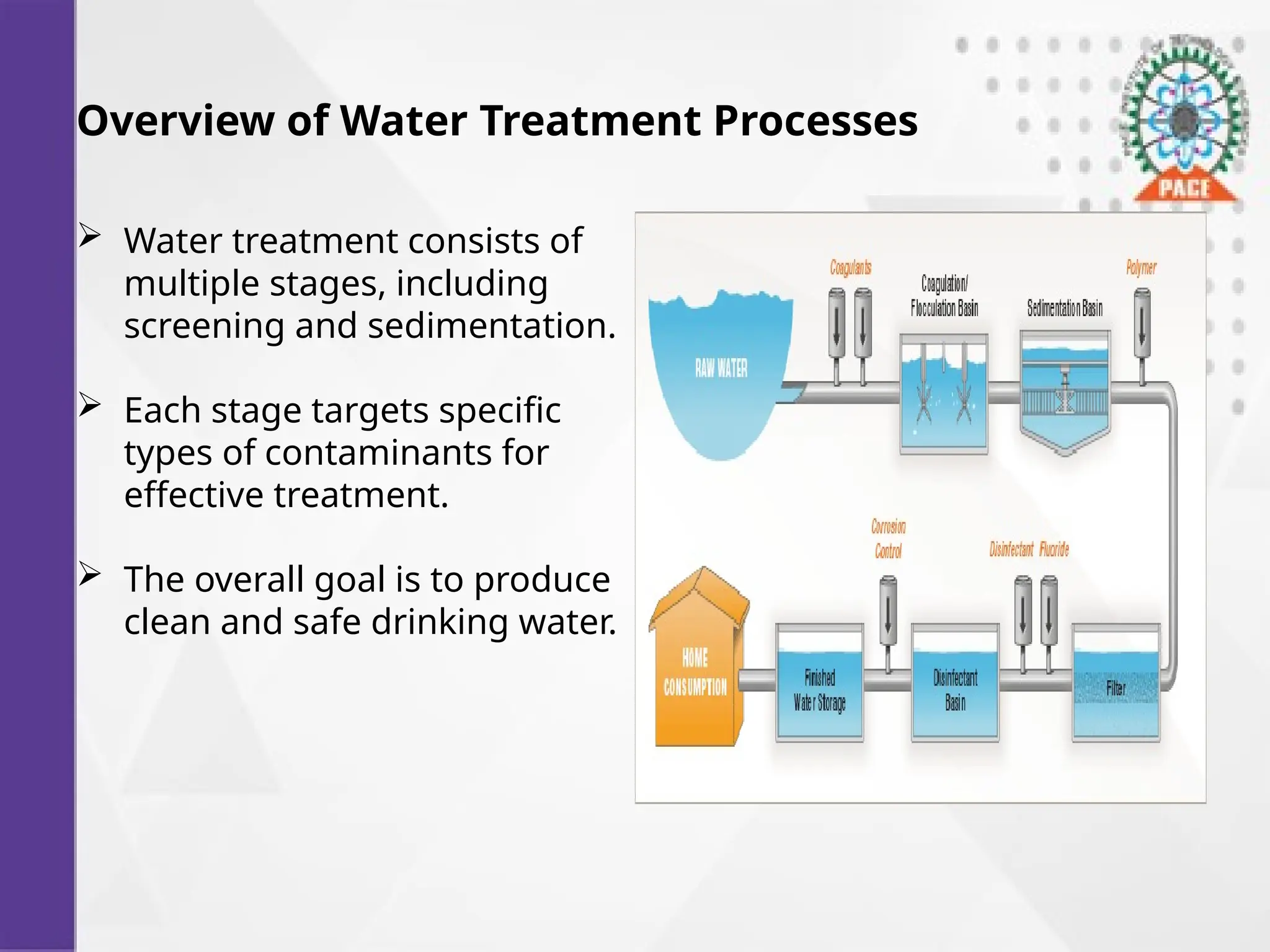

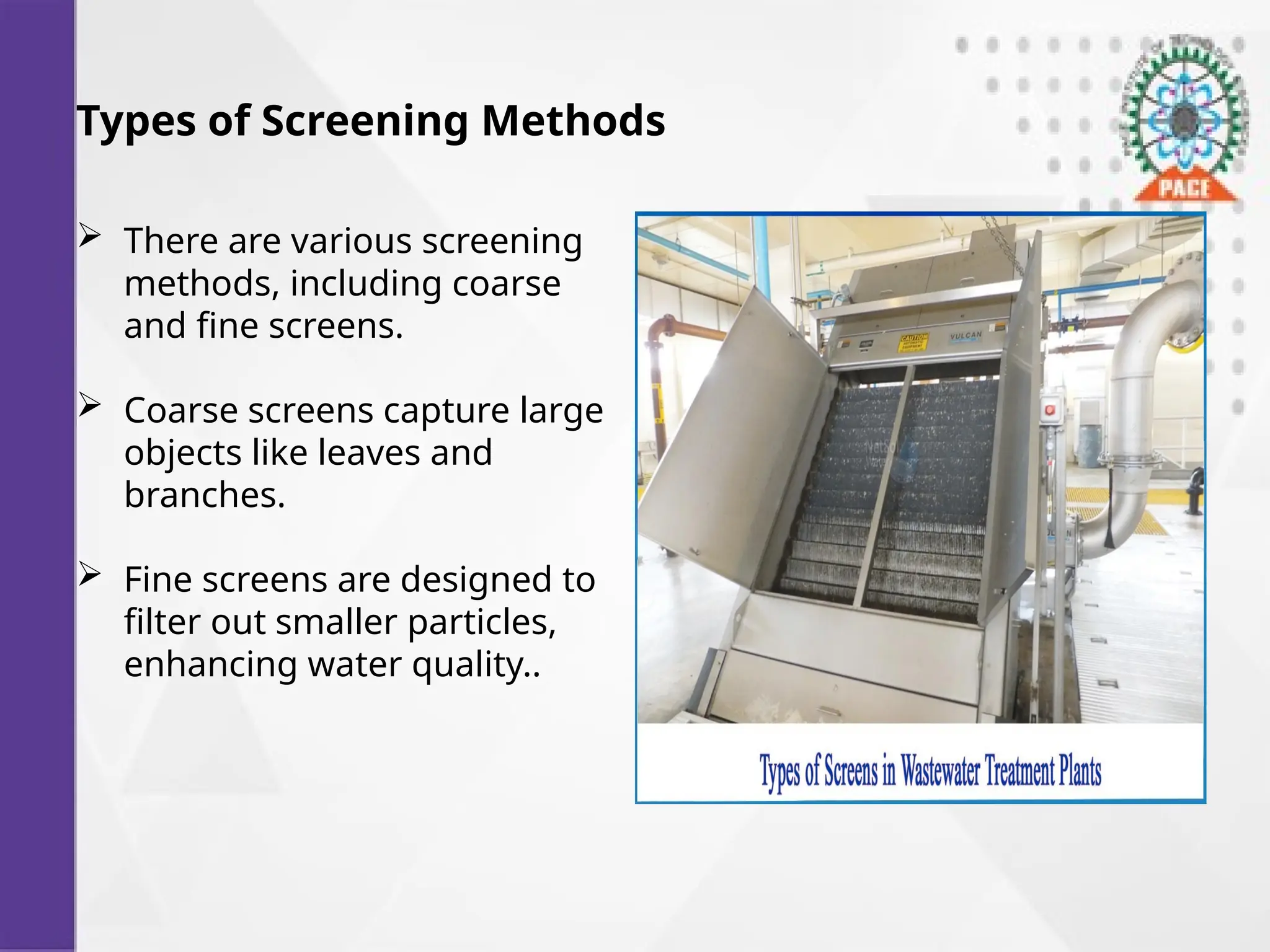

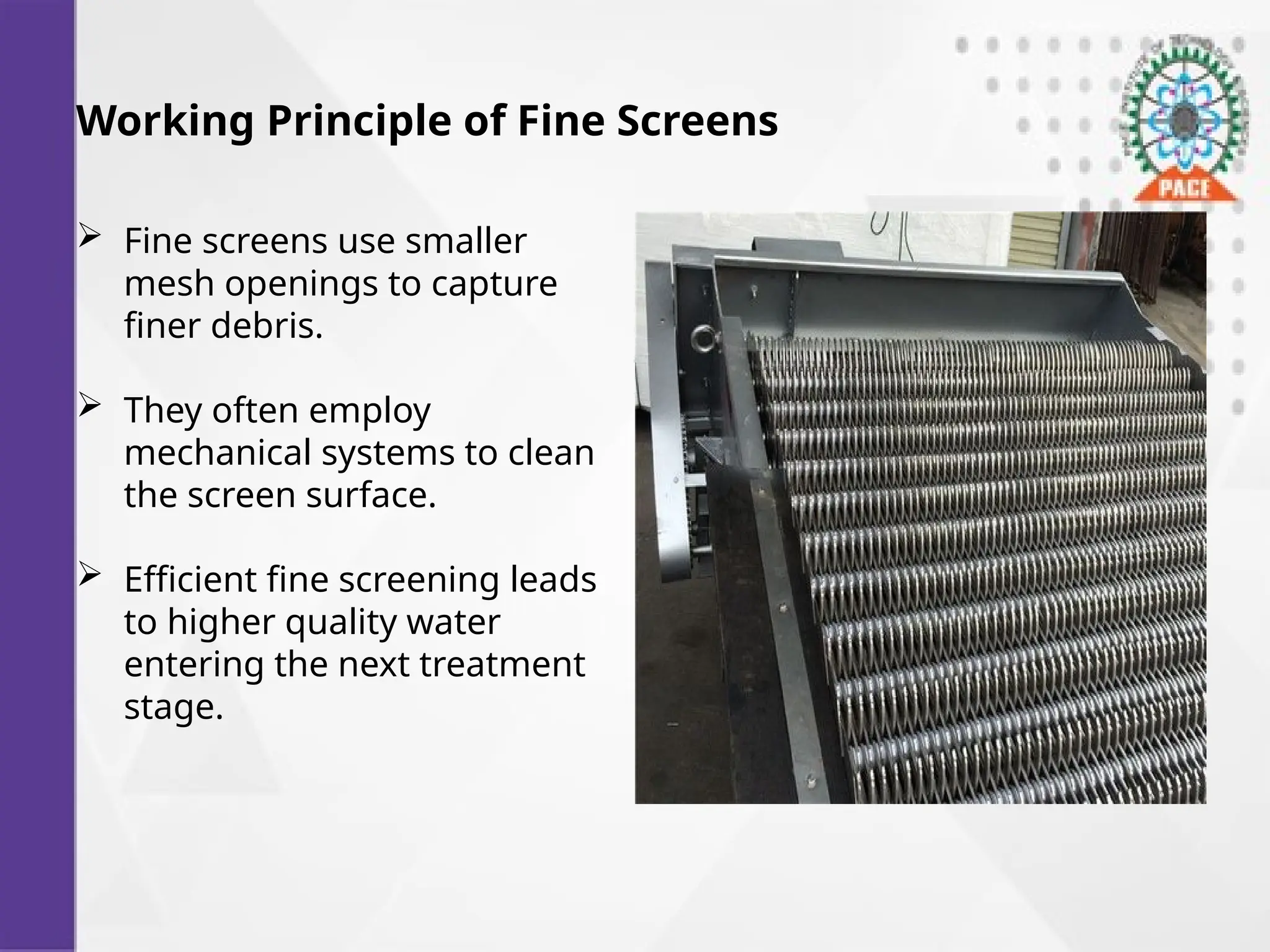

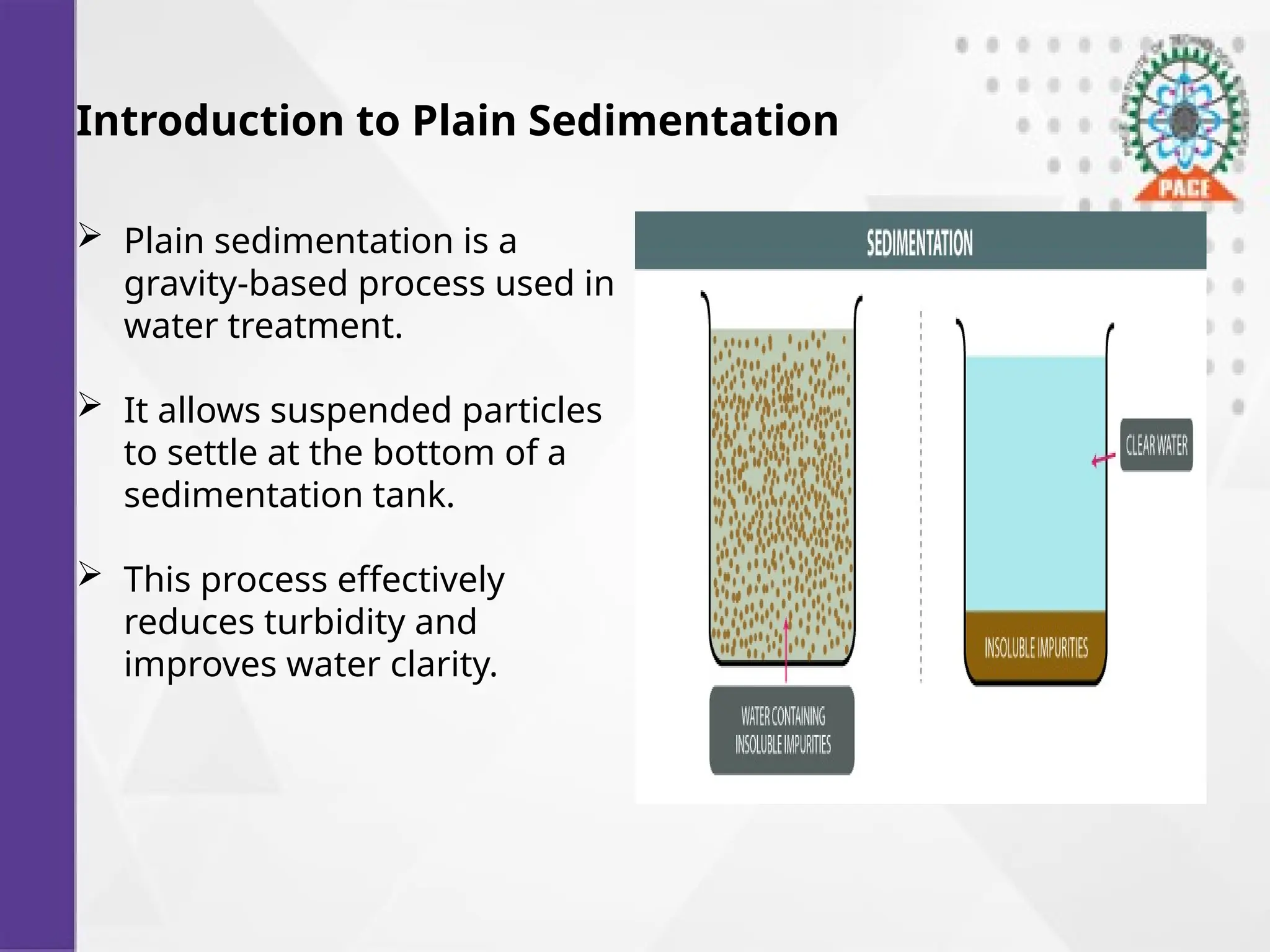

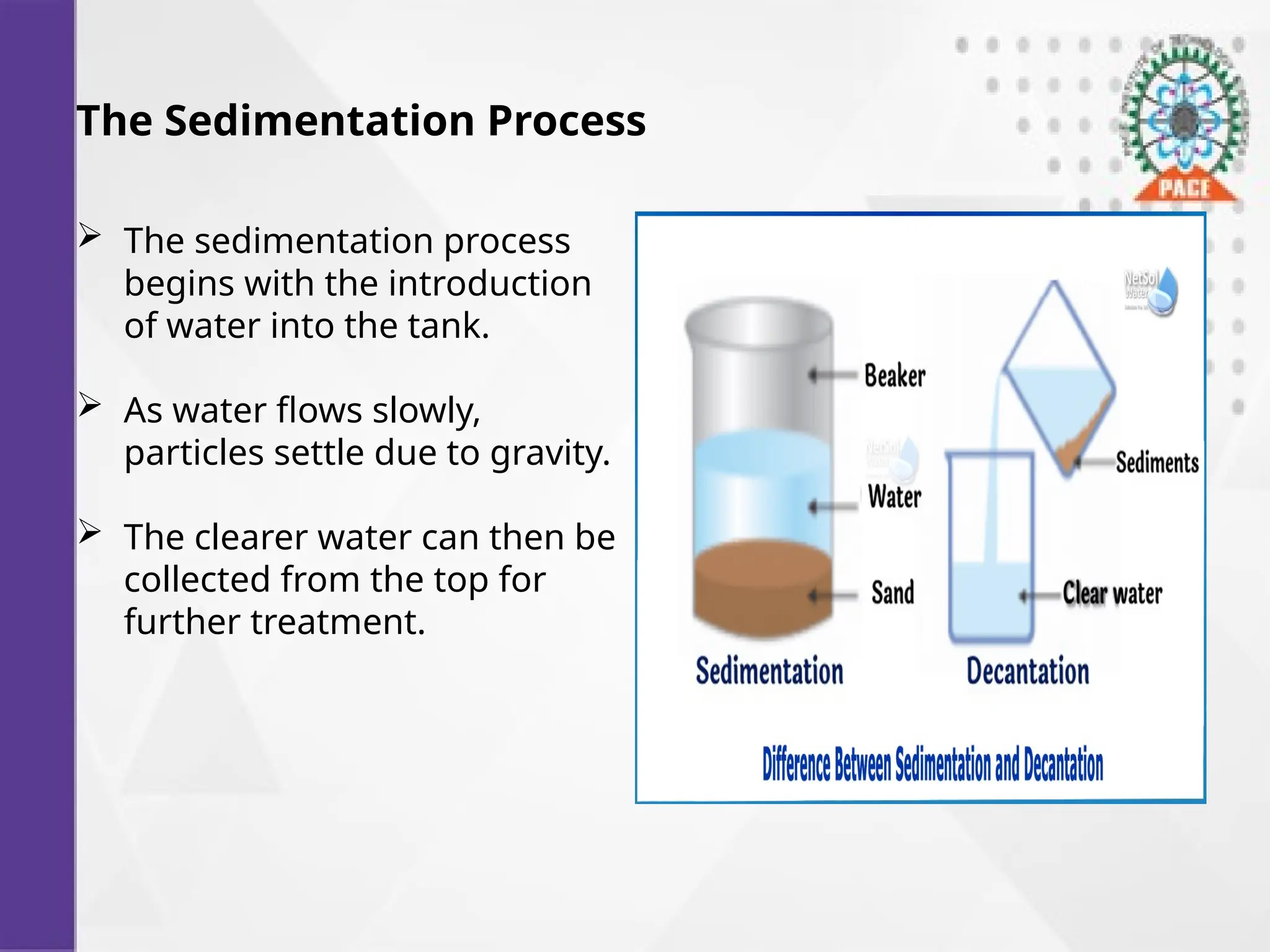

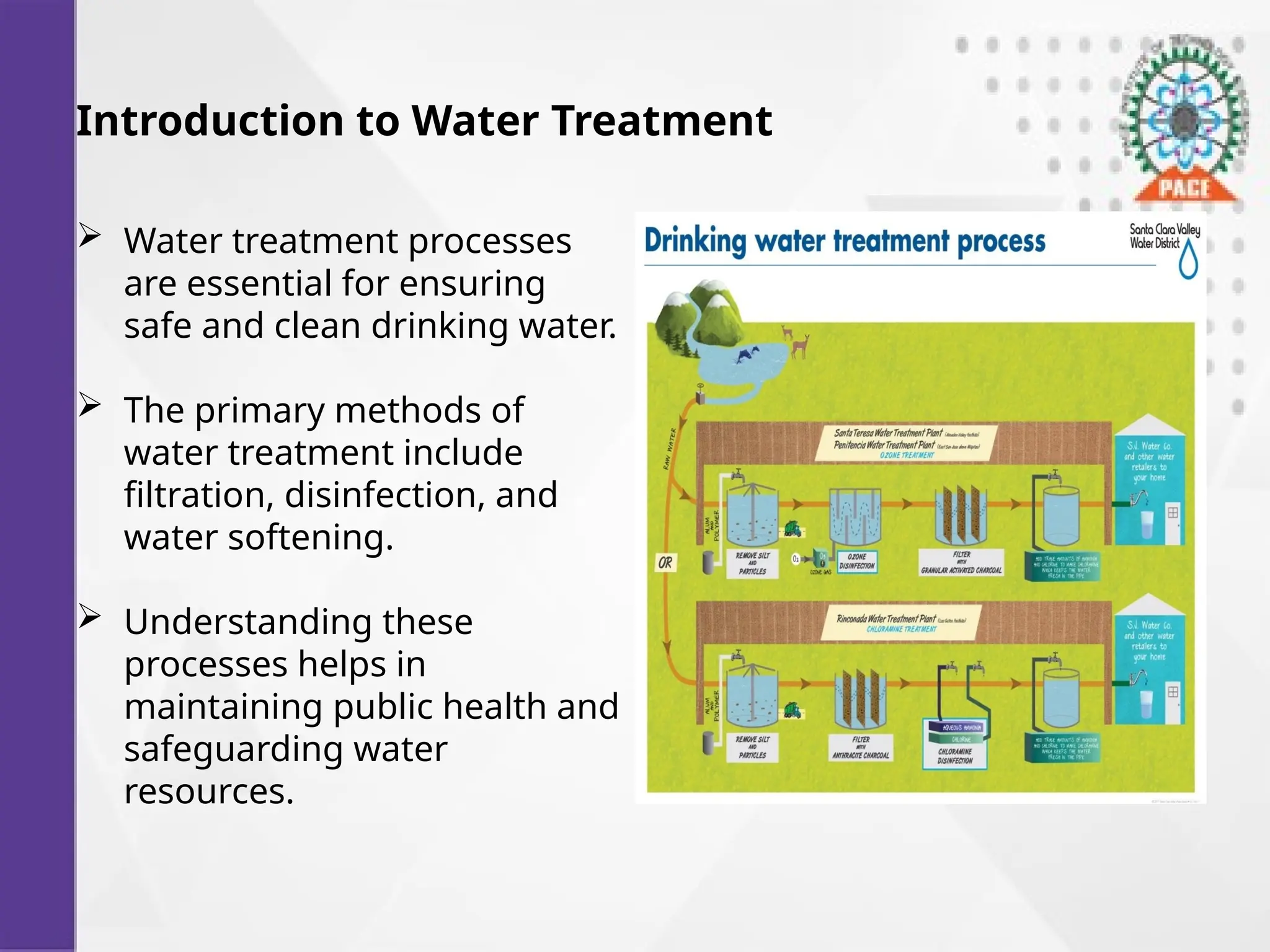

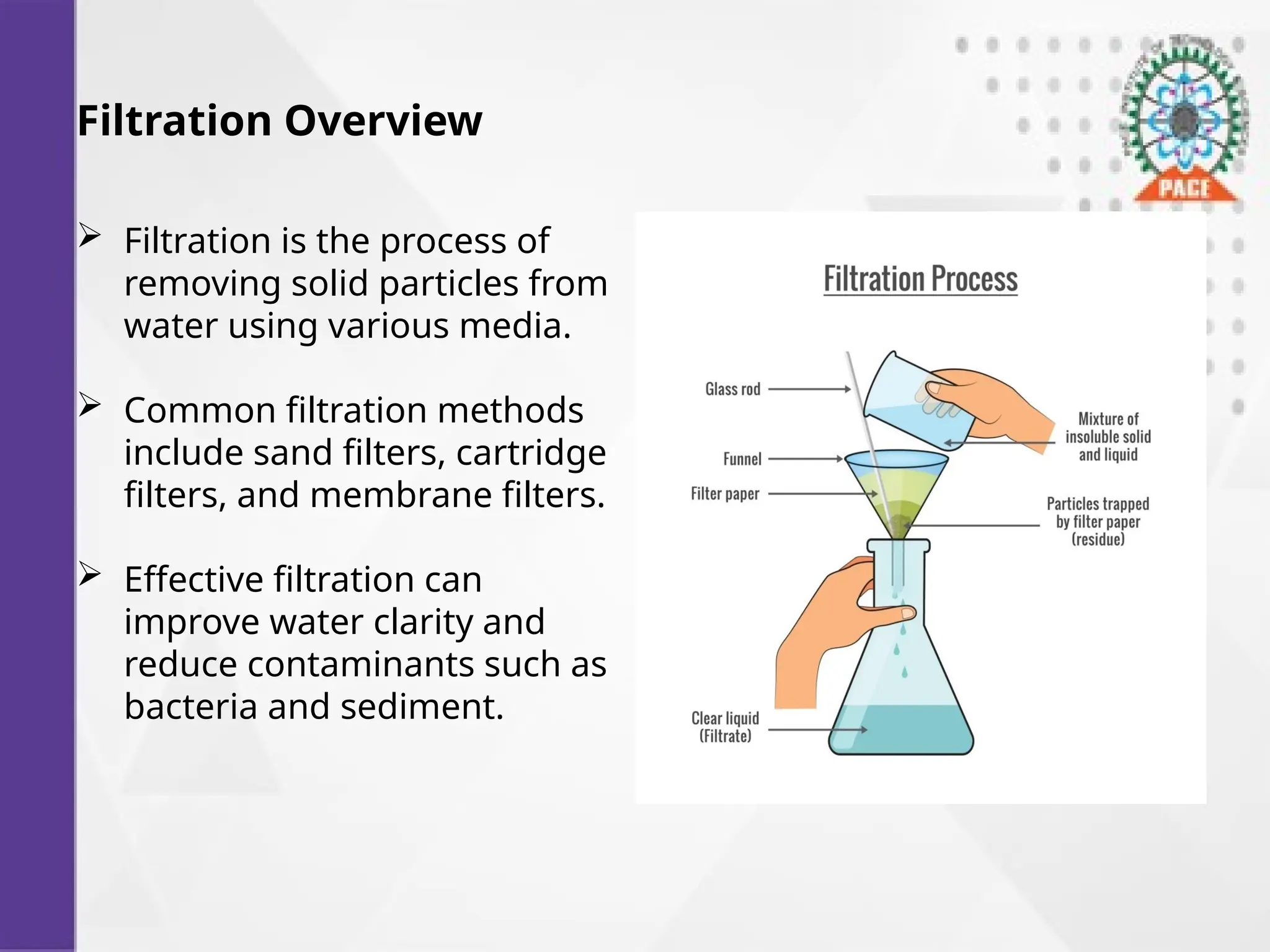

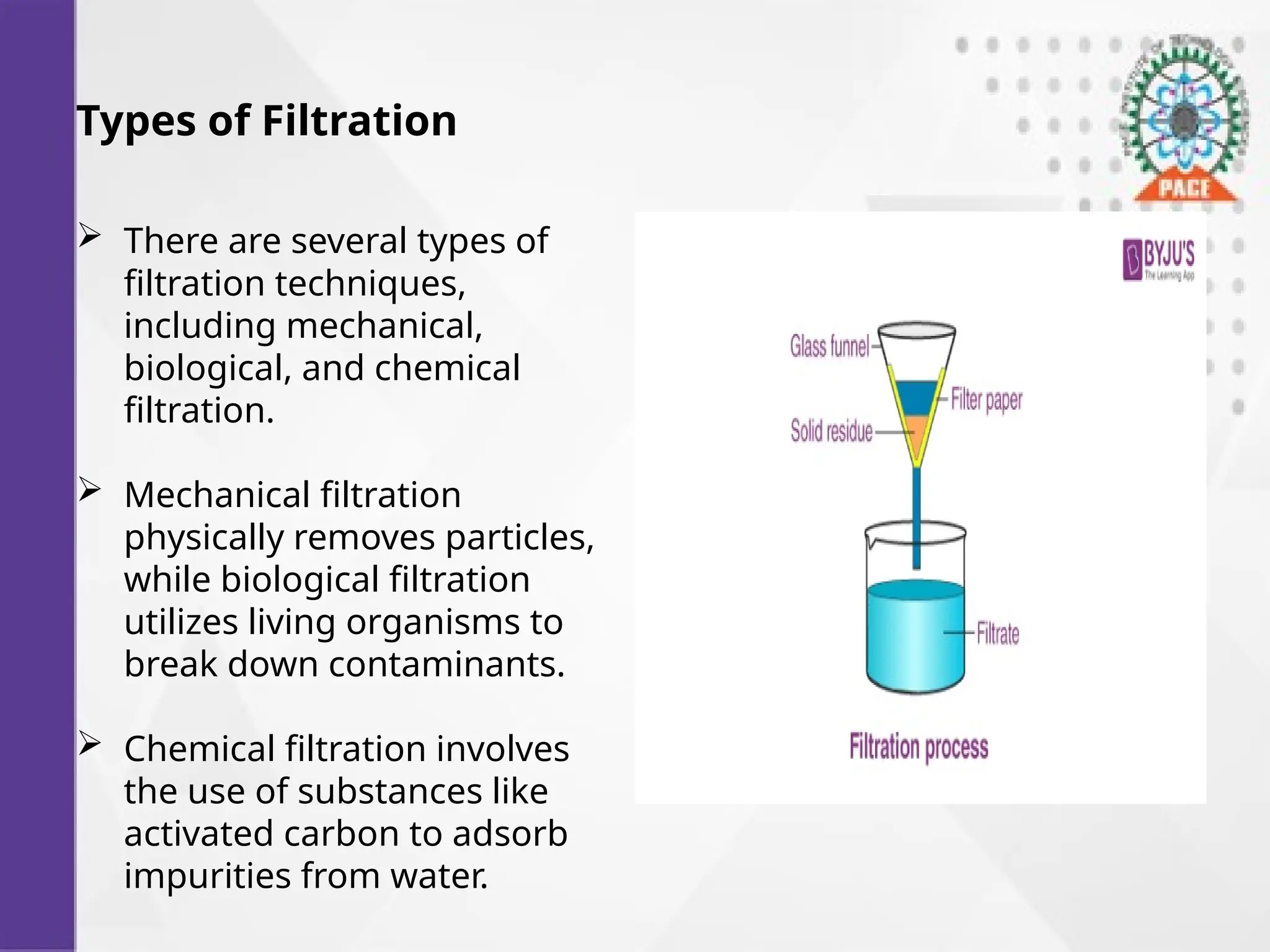

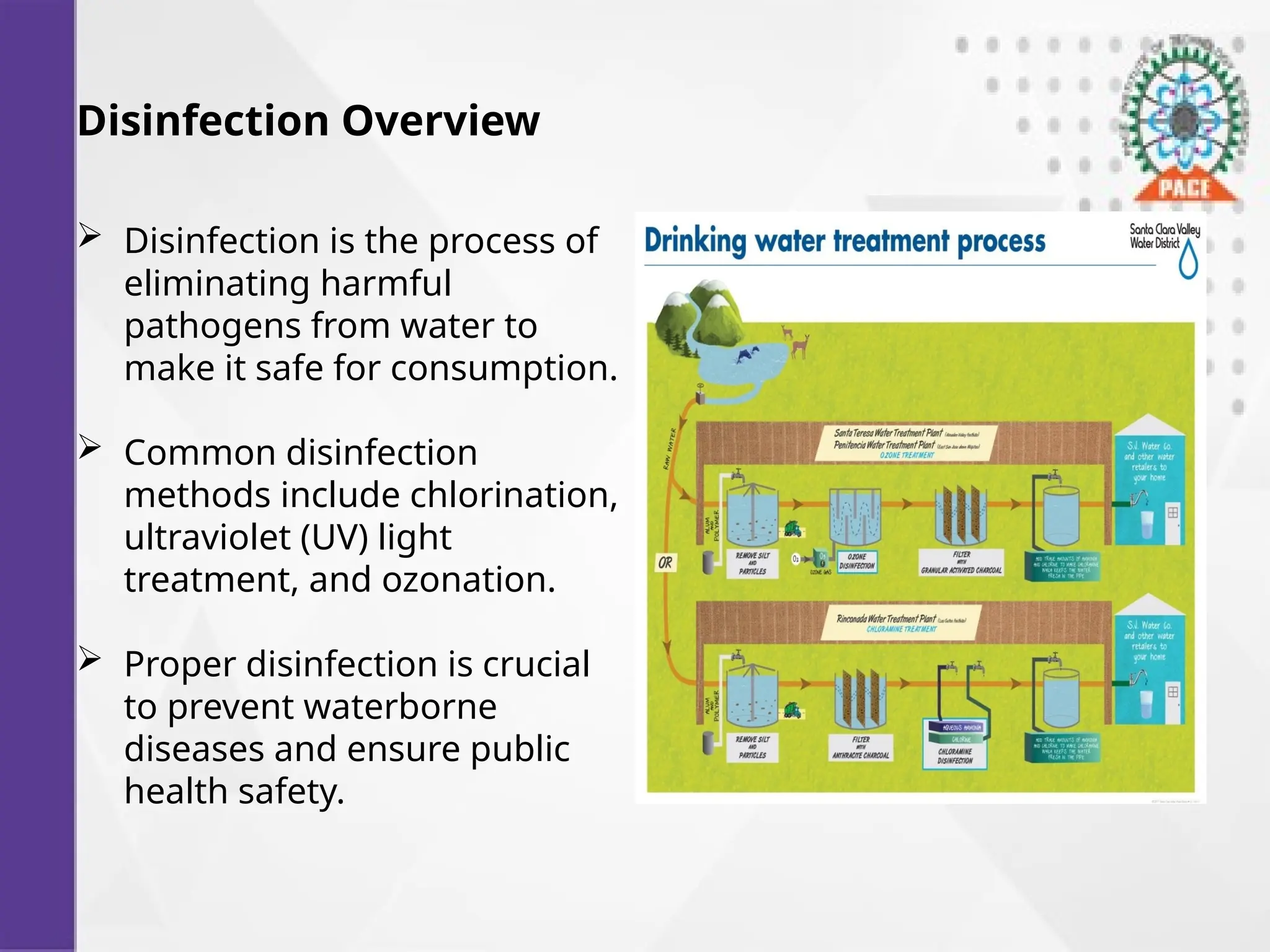

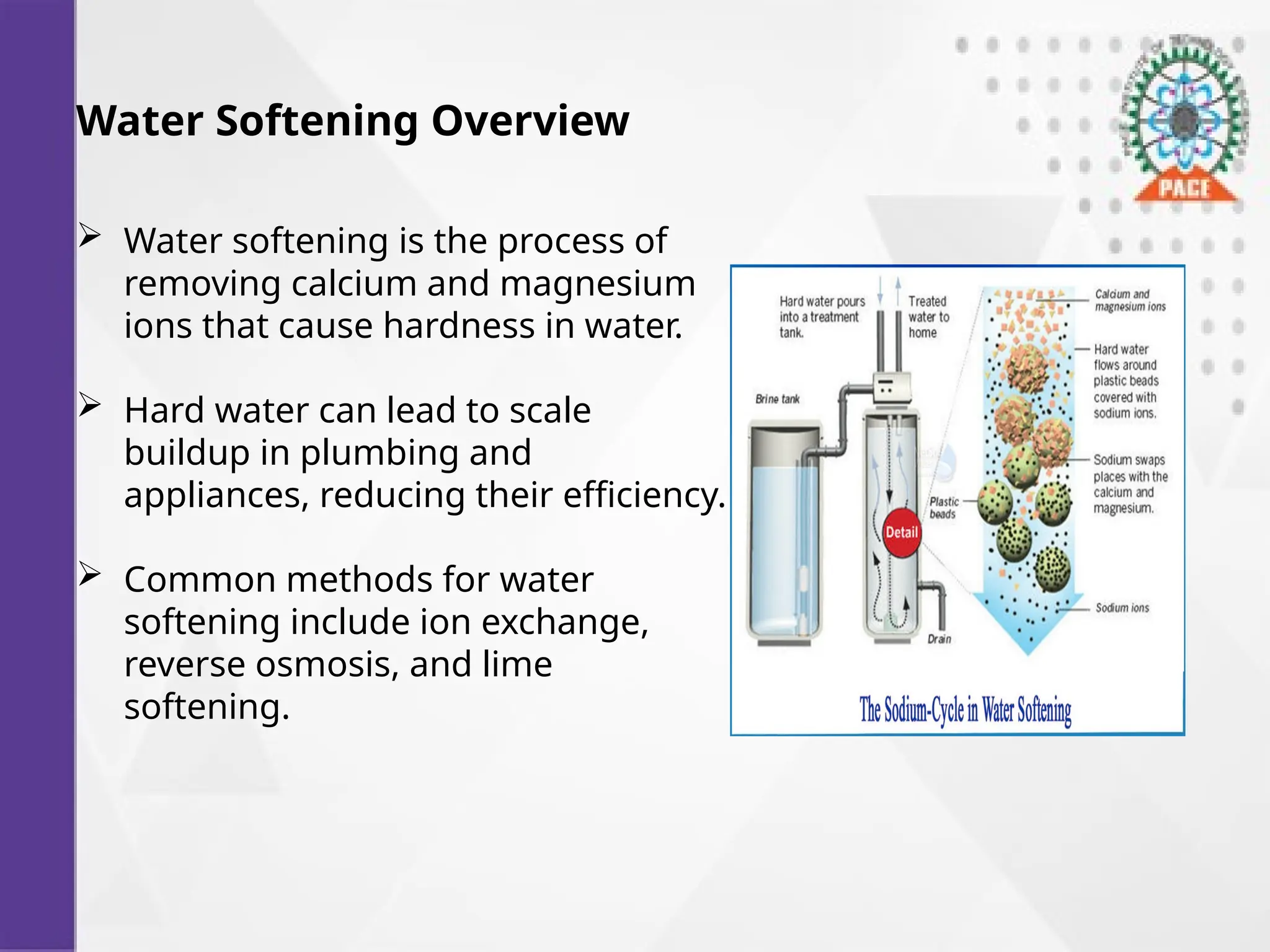

The document outlines key concepts in environmental engineering related to water collection, conveyance, and treatment for civil engineering students. It covers various types of water intakes, pumps, conduits, pipes, and water treatment processes such as sedimentation, filtration, and disinfection. Understanding these components and their interactions is crucial for effective water resource management and ensuring safe drinking water.