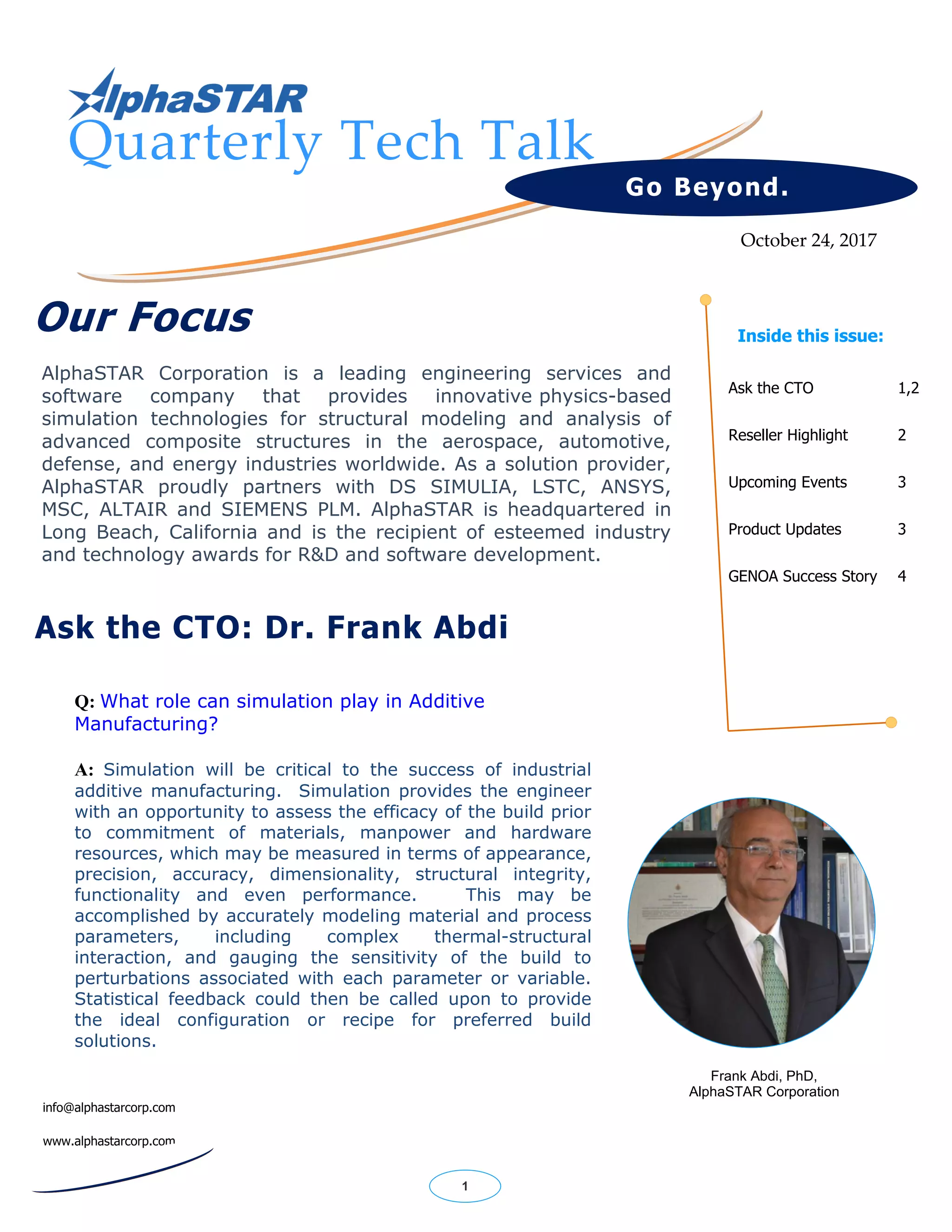

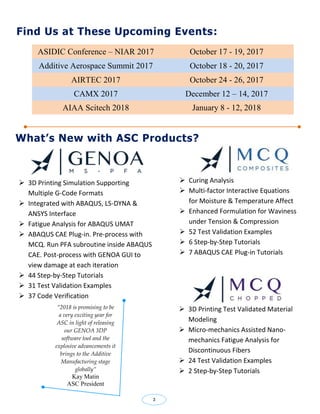

The document discusses the essential role of simulation in additive manufacturing (AM) for improving build efficacy before resource commitment, emphasizing the need for advanced personnel training and technological breakthroughs to drive growth in the industry. It highlights Alphastar Corporation's contributions to composite materials' structural analysis and the importance of additive manufacturing in the industrial landscape. Additionally, it showcases Multiangle Virtual Technology's efforts in the Chinese market and Hindustan Aeronautics Limited's success using simulation software for analyzing rotorcraft durability.