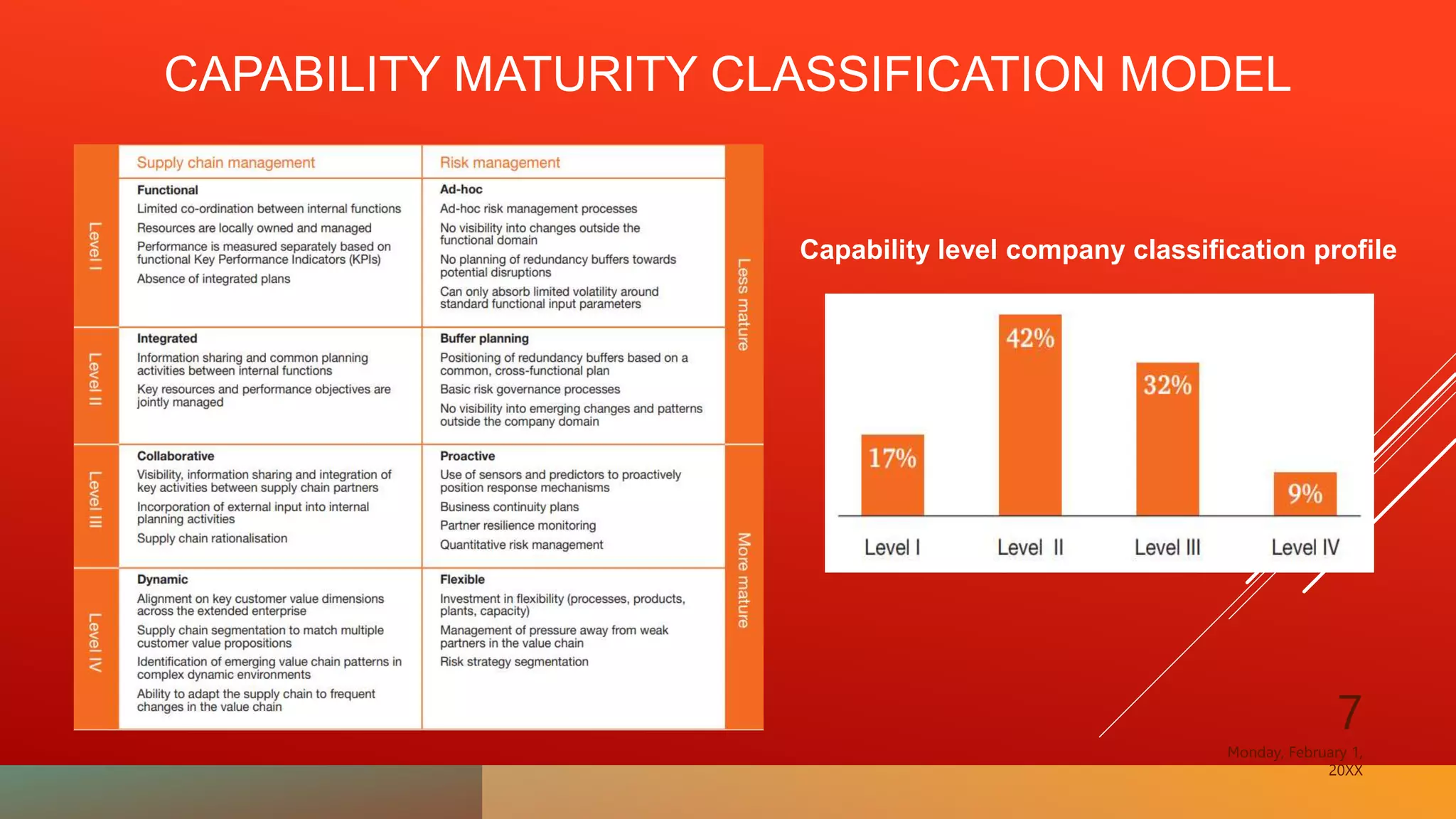

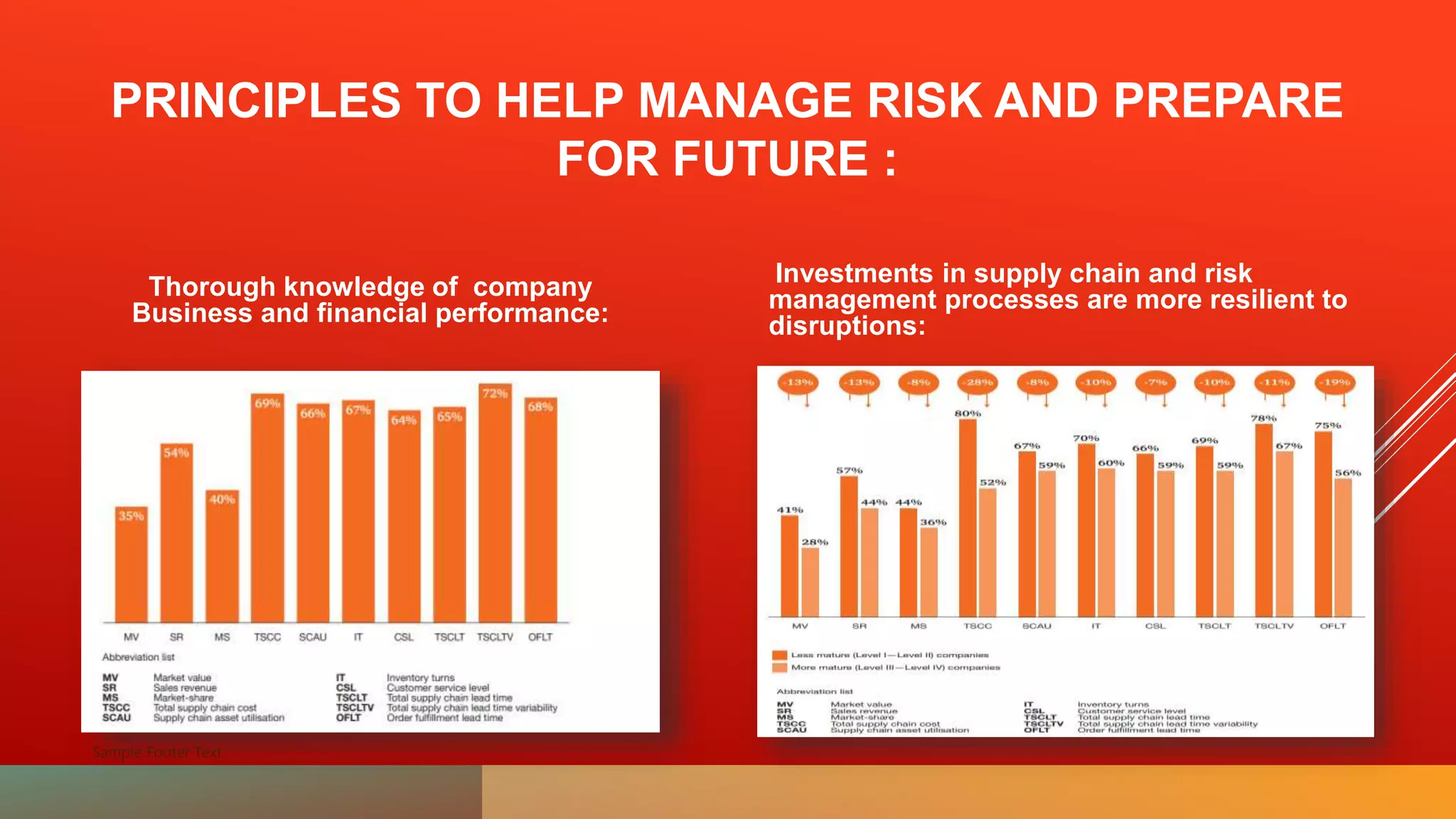

The PwC report provides guidance on developing a resilient supply chain through effective risk management. It outlines four levels of supply chain operations and risk management maturity. Higher levels involve greater external collaboration, proactive risk response, and dynamic adaptation to risk. The report advises companies to thoroughly understand their business and supply chain, invest in risk management processes, regularly involve risk specialists, and segment and mitigate risks. It also provides questions for companies to assess how changes may increase complexity and how to ensure sufficient partner oversight.