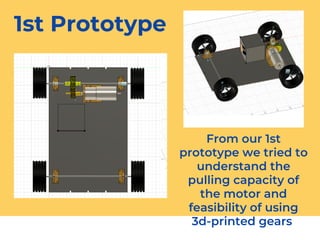

1. The document describes two prototypes of a remote controlled vehicle for payload towing.

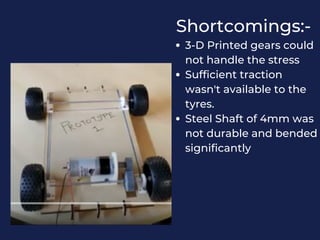

2. The first prototype used 3D printed gears that could not handle stress and plastic tires that lacked sufficient traction.

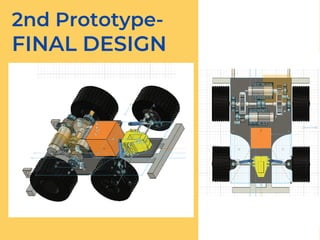

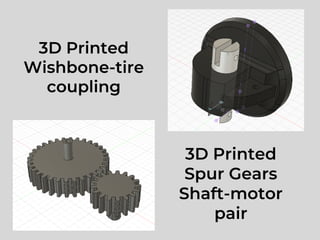

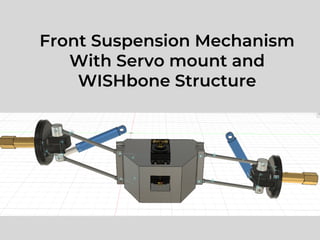

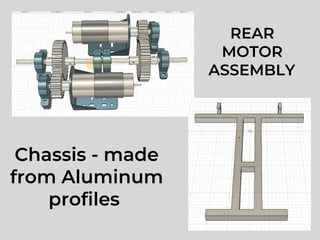

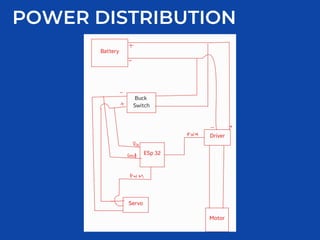

3. The second and final design improved on structural integrity with an aluminum chassis, acrylic base, and tougher PLA 3D printed gears while adding features like double wishbone suspension and remote control via an ESP 32 module.