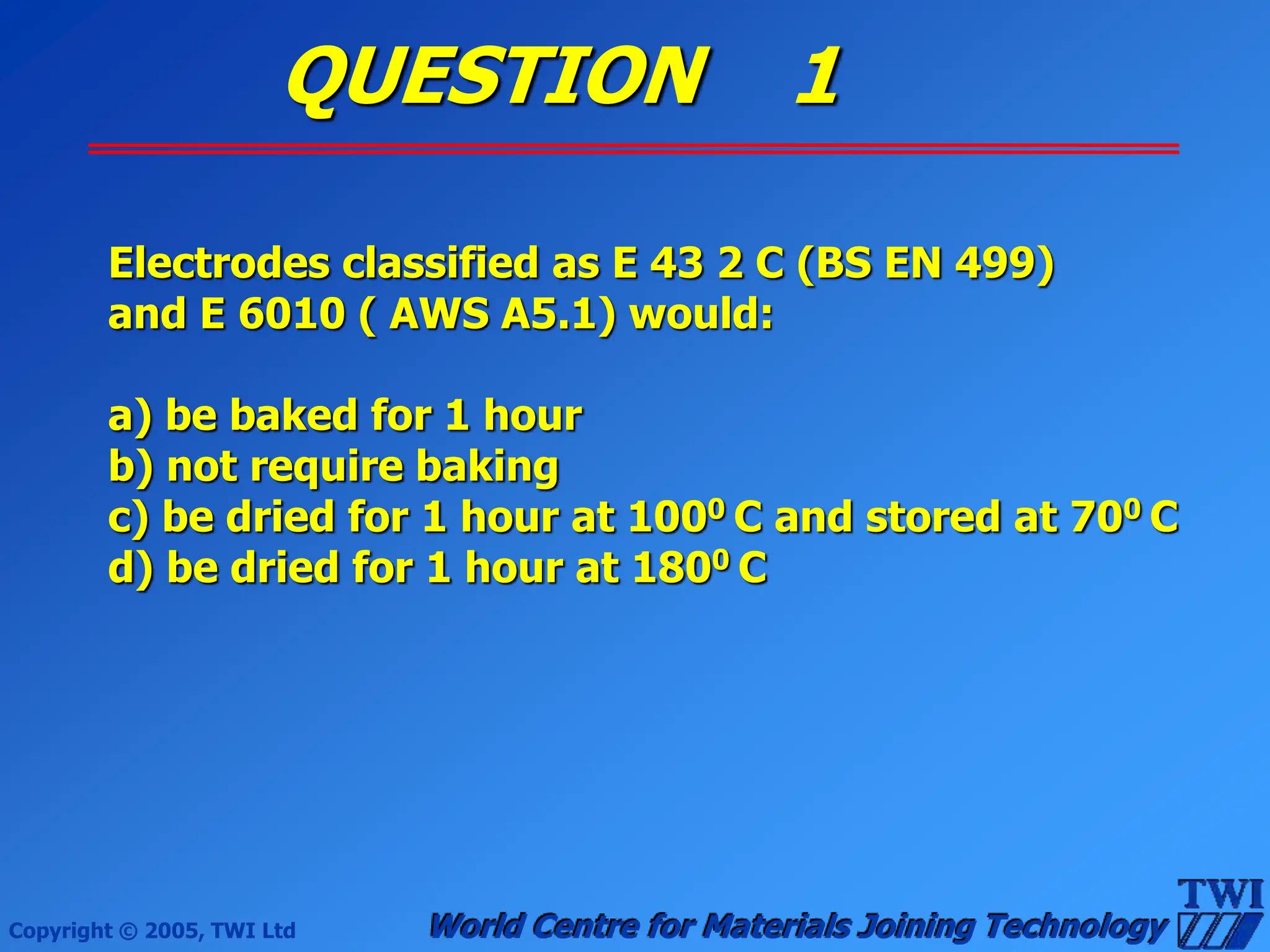

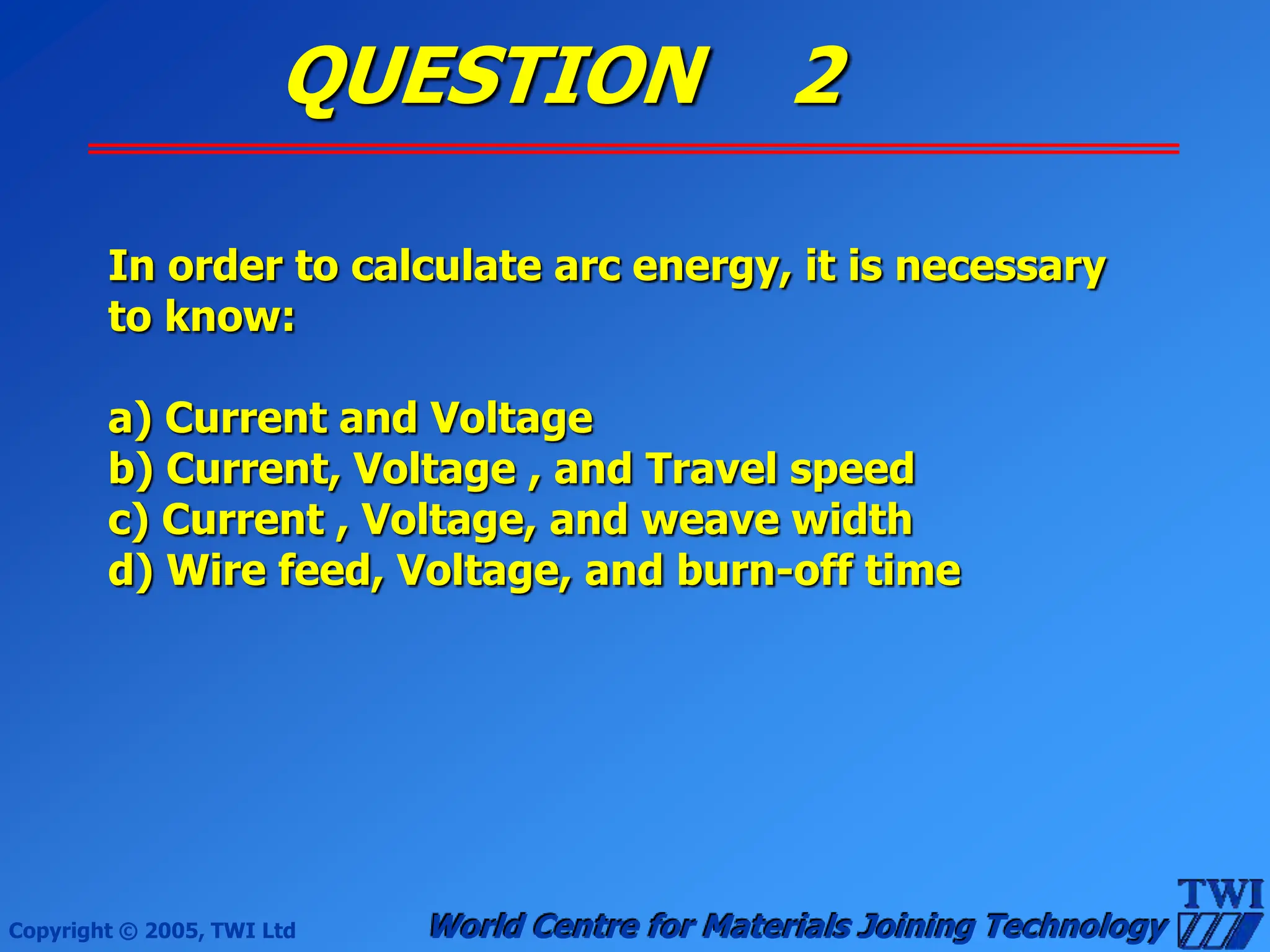

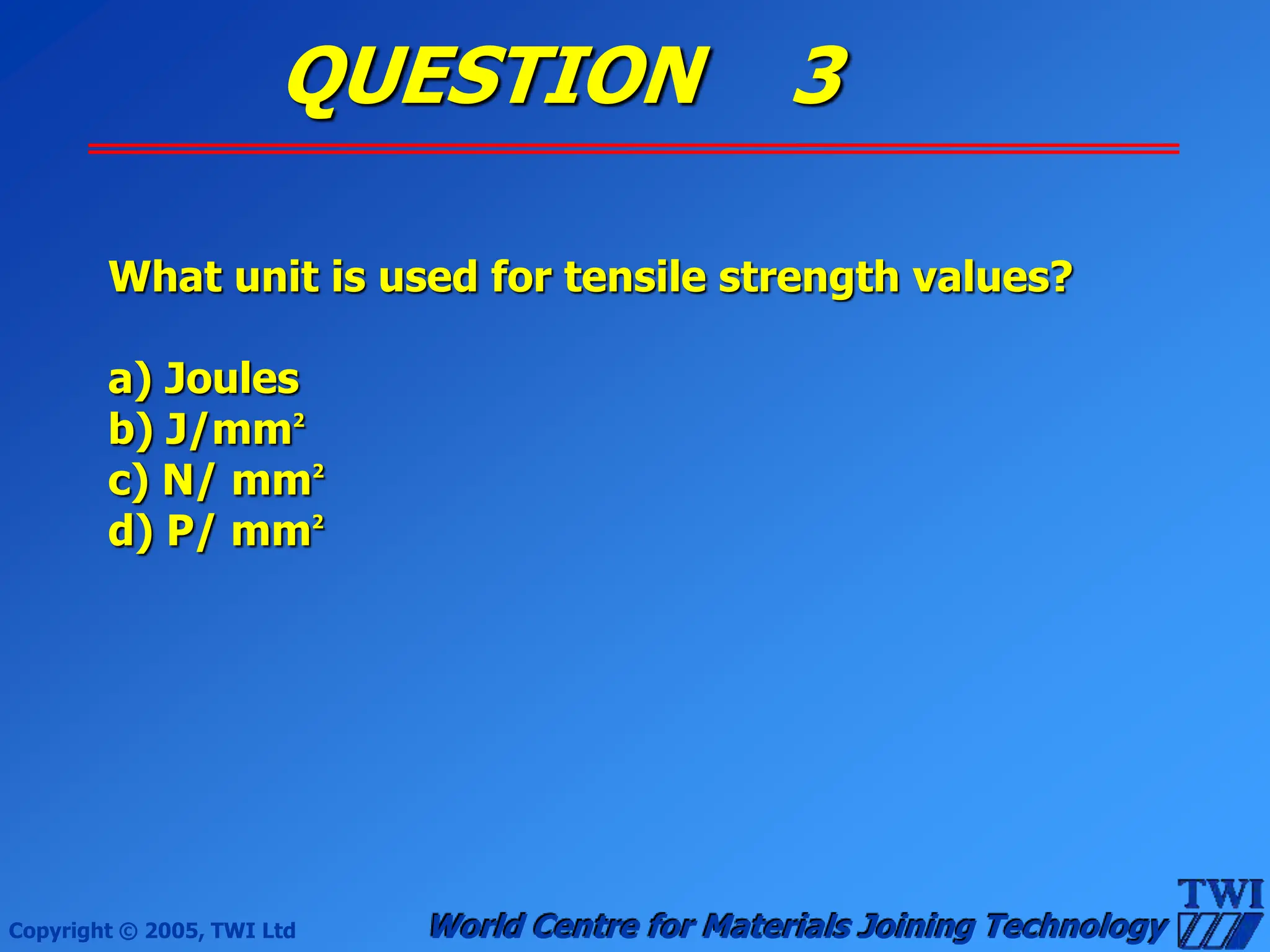

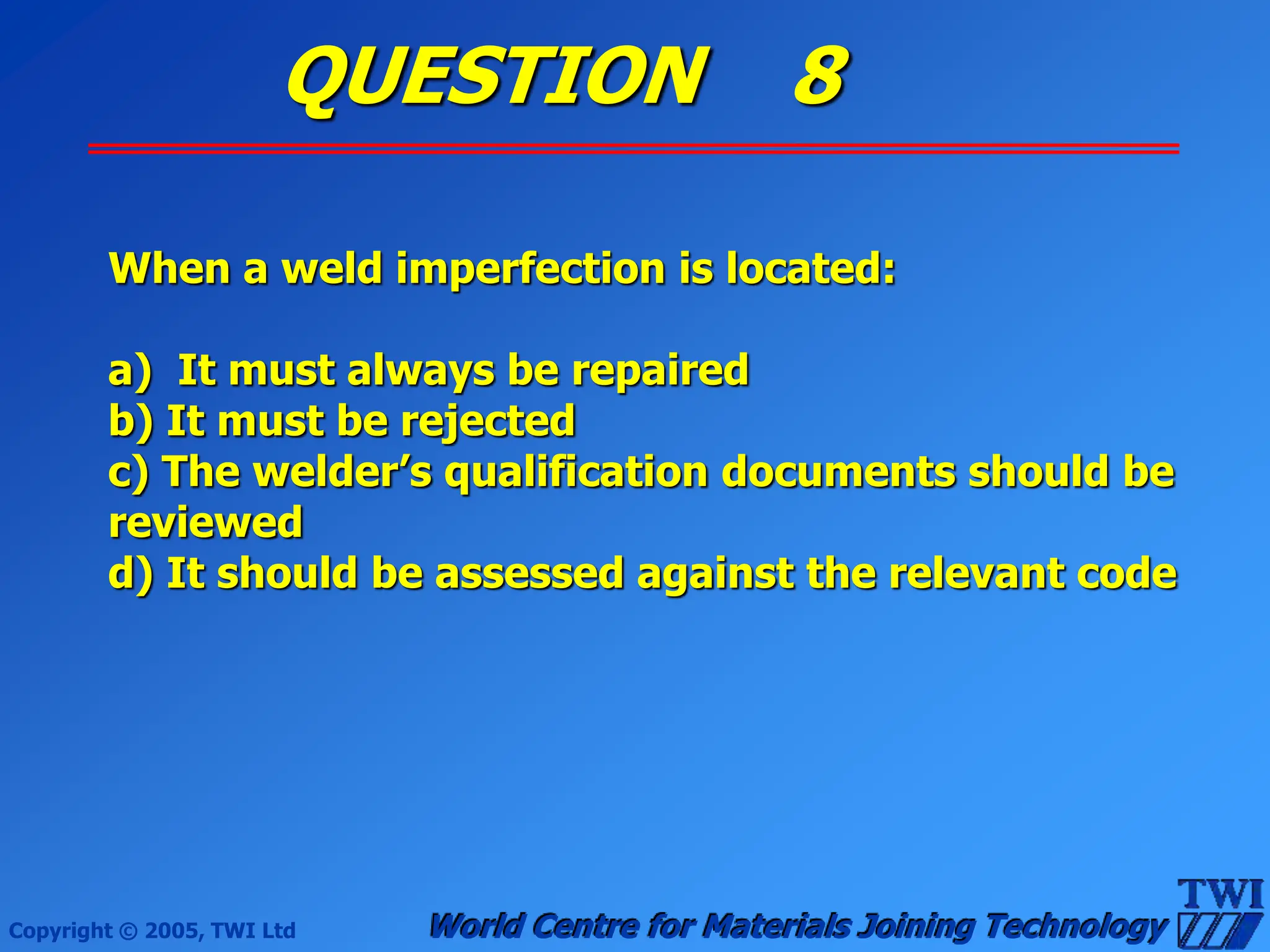

The document consists of multiple-choice questions related to welding technology, covering topics like electrode classifications, arc energy calculations, tensile strength units, radiographic techniques, and welding procedures. Each question is paired with an answer, offering insights into standard practices and technical knowledge in the field of materials joining. It serves as an educational resource for those studying or assessing their understanding of welding and associated non-destructive testing methods.