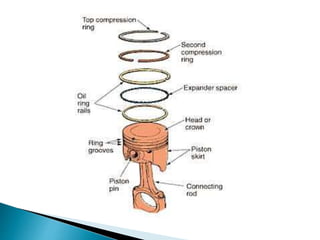

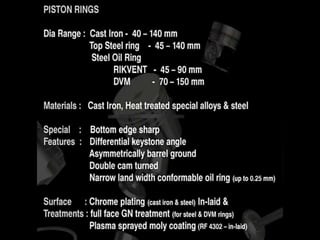

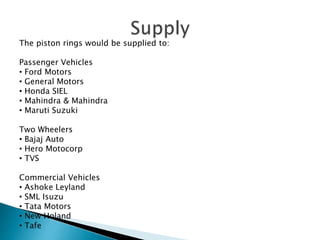

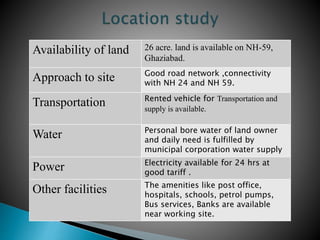

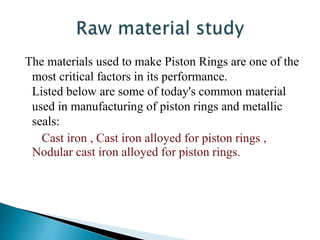

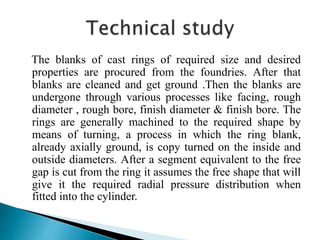

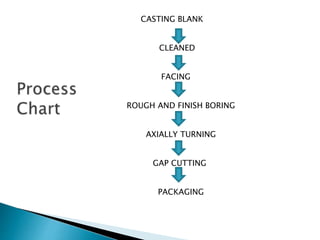

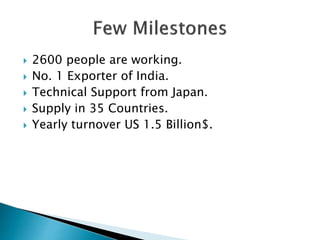

The document discusses a proposal for starting a piston ring manufacturing business. It covers conducting demand and supply studies, selecting a location with adequate infrastructure, sourcing raw materials, and outlining the manufacturing process which involves casting, cleaning, grinding, machining, and quality control steps. The proposal suggests the business could supply to automotive and engine original equipment manufacturers and generate sales through quality products and marketing.