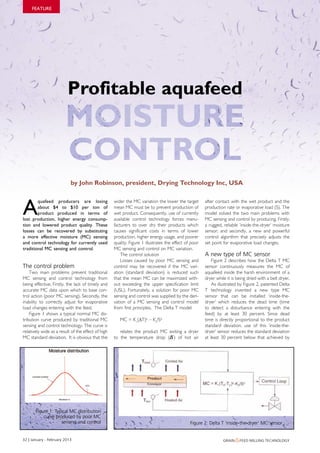

The document discusses advancements in aquafeed moisture control technology aimed at reducing costs and improving product quality in the drying process. It introduces a new 'inside-the-dryer' moisture sensor and control model that effectively minimizes standard deviation in moisture content, leading to significant energy savings and reduced production losses. Additionally, the document highlights the importance of accurate control algorithms for optimizing moisture content against evaporative load changes in aquafeed production.