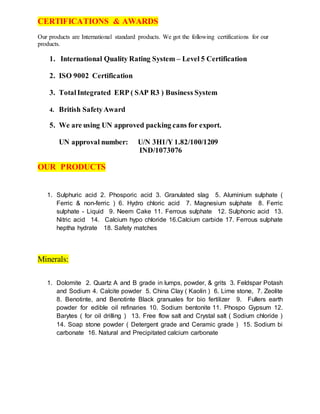

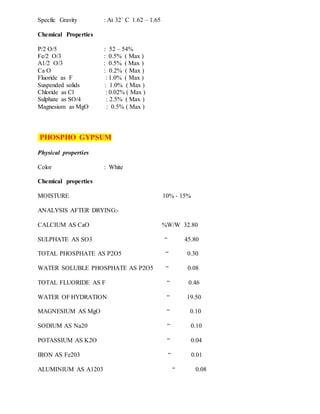

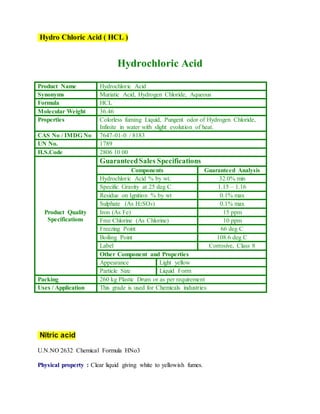

This document provides information about Vaikash Exims, an Indian exporter of various chemicals and minerals. It introduces the company and its owner, K.K. Kumar, who has over 20 years of experience in export. The company exports products to destinations around the world, especially in Asia, Africa, and the Middle East. The document lists the company's certifications and awards and provides details on its product offerings, including chemical analysis reports and specifications for various chemicals and minerals. It describes common uses of the chemicals in different industries.

![This can be even written in a more compact way as AS2H2 using the cement chemist notation

(CCN) to represent the hereabove mentionned oxides respectively (A = Al2O3, S = SiO2, H =

H2O).

This format is also useful for describing the firing process of clay as the kaolinite loses the 2

water molecules, termed the chemical water, when fired to a high enough temperature. This is

different from clay's physical water which will be lost simply due to evaporation and is not a part

of the chemical formula.

Kaolin. (unknown scale)

A folk medicine use is to soothe an upset stomach, similar to the way parrots (and later, humans)

in South America originally used it.

Kaolin is, or has been, used as the active substance in liquid anti-diarrhea medicines such as

Kaomagma and Kaopectate. Such medicines were changed away from aluminium substances due

to a scare over Alzheimer's disease[citation needed], but have since changed back to compounds

containing aluminium as they are more effective.

Kaolin is known in traditional Chinese medicine by the name chìshízhī (赤石脂),[citation needed]

literally "crimson stone resin".

In Africa, kaolin is sometimes known as kalaba (in Gabon and Cameroon), calaba, and

calabachop (in Equatorial Guinea). It is used for facial masks or soap and is eaten for pleasure

or to suppress hunger, a practice known as geophagy. Consumption is greater among women,

especially during pregnancy.

This practice is also seen among African-American women in the Southern United States,

especially Georgia. There, the kaolin is called white dirt, chalk or white clay.

FERRIC SULPHATE - Liquid

It is used in dyeing as a mordant, and as a coagulant for industrial wastes. It is also used in

pigments, and in pickling baths for aluminum and steel. Medically it is used as an astringent and

styptic.](https://image.slidesharecdn.com/58ed54b7-0592-4088-b1d0-3752f2e0ea0d-160330141349/85/Product-profile-17-320.jpg)