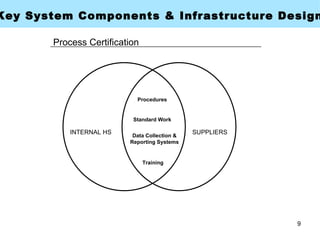

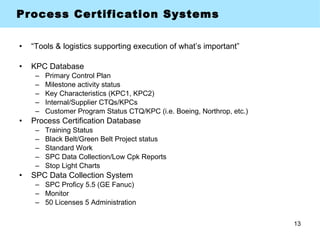

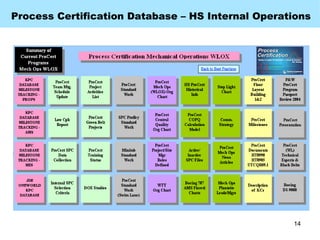

The document summarizes Hamilton Sundstrand's implementation strategy for process certification (Six Sigma) at their Windsor Locks, Connecticut facility. Key aspects included establishing a process certification council and steering committees to oversee the effort. Standard work, procedures, systems and infrastructure were developed to support data collection, analysis and reporting. Training programs were implemented to develop black belts and green belts across internal operations and supplier sites. The results were reported as reductions in cost of poor quality, variation and improvements in customer satisfaction scores and certification levels.