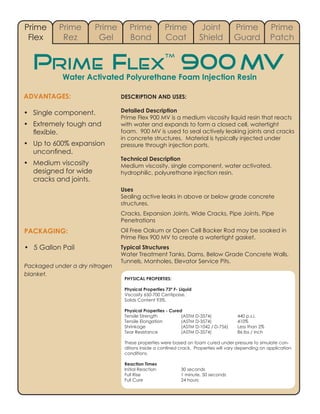

Prime Flex 900 MV is a single-component, water-activated polyurethane foam for sealing cracks and joints in concrete structures. It has a medium viscosity, expands up to 600% when cured, and forms a flexible closed-cell foam. It is used to inject into actively leaking cracks and joints in water tanks, dams, and other concrete structures to create a watertight seal. Proper storage, mixing, application procedures and safety precautions should be followed.