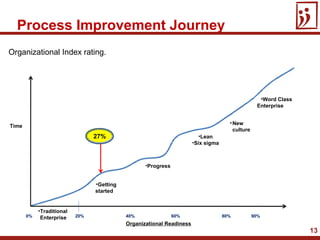

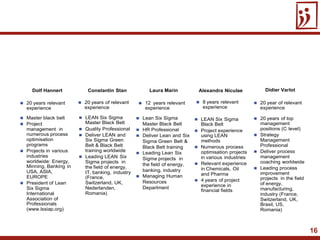

This document discusses process improvement approaches like Lean management, Six Sigma, and business process management. It explores the origins of the word "munca" in several languages and how process improvement can transform difficult work into something more efficient. The document presents Ascendis Process Management as a company with experts in process optimization who help clients improve processes and transition organizations from a traditional to a world-class model through tools like Lean and Six Sigma.