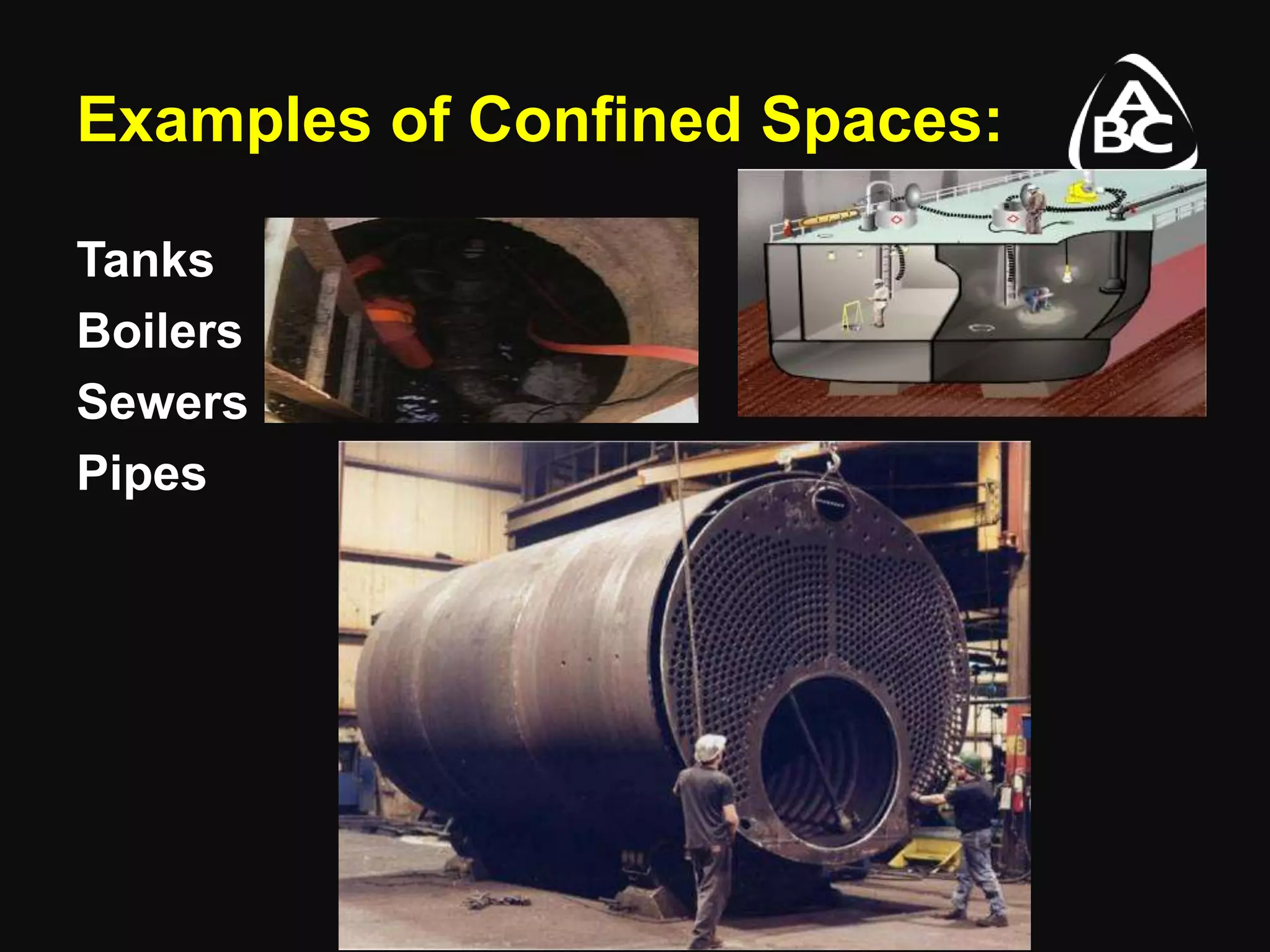

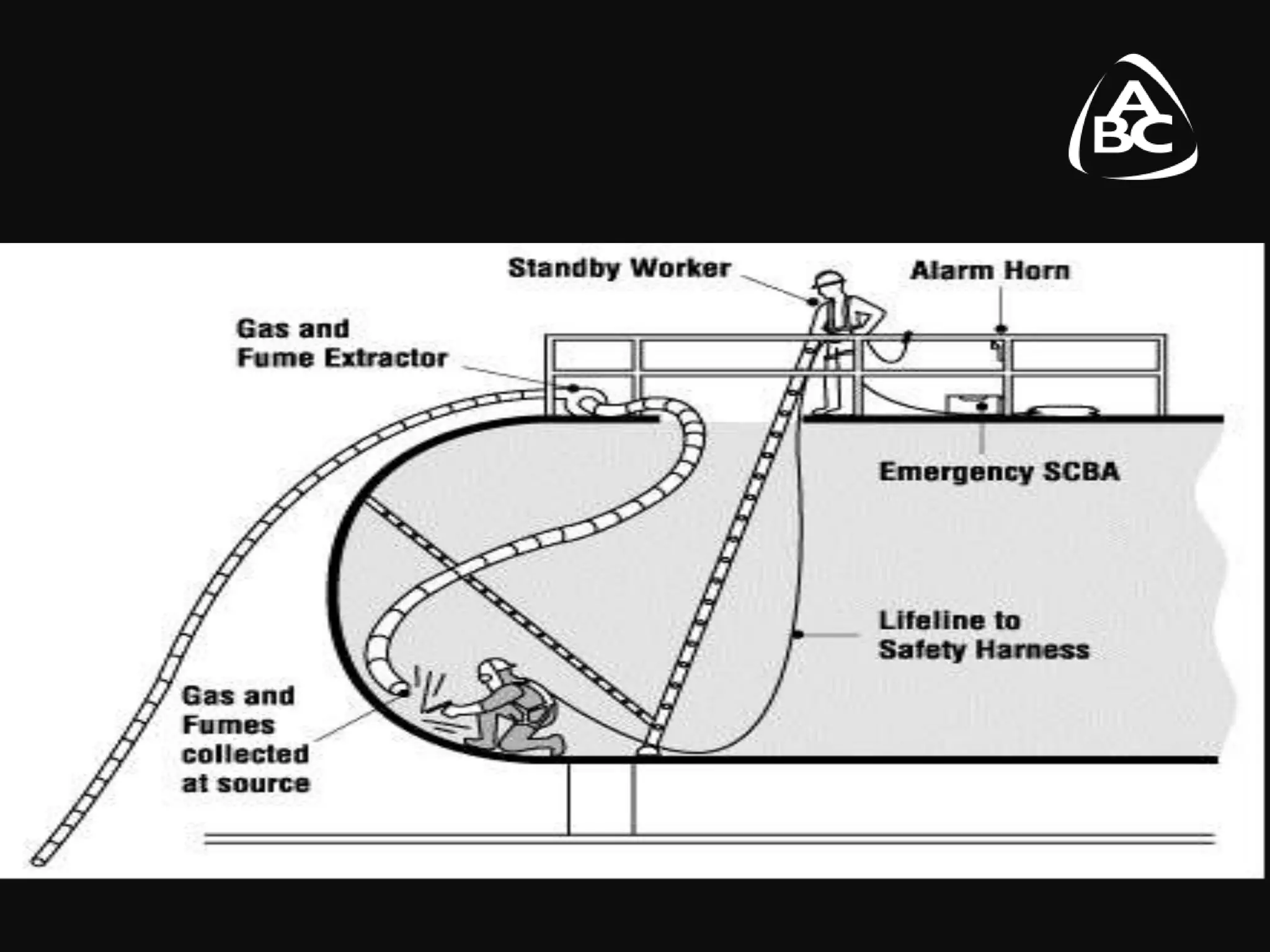

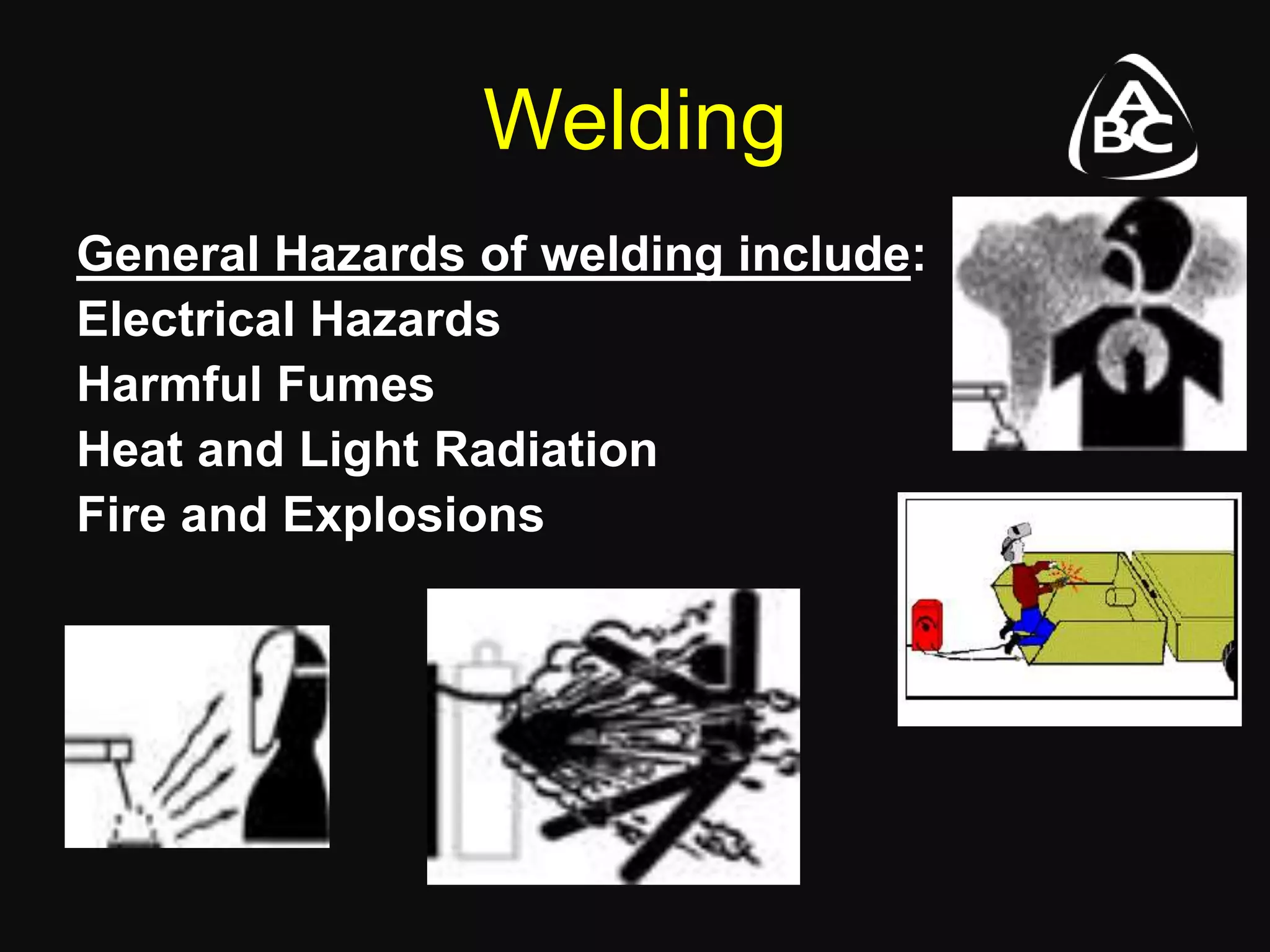

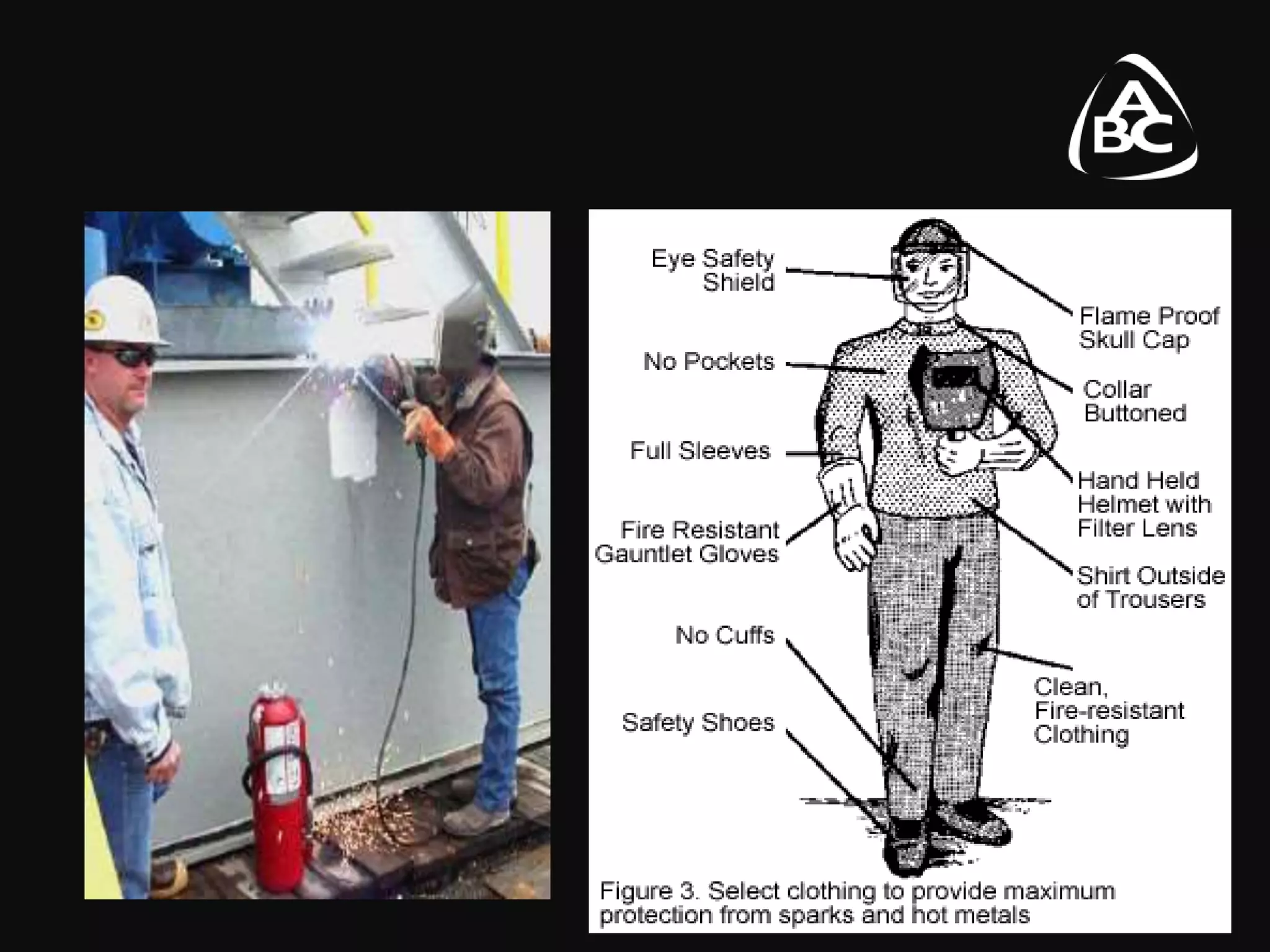

This document discusses various topics relating to facility safety management. It addresses the importance of providing appropriate safety gear for employees, clearly identifying dangerous areas, ensuring visibility in low-light areas, proper protective equipment for electrical work, availability of first aid kits, risks of cell phone use and confined spaces. Requirements are outlined for eye wash stations, emergency showers, and safely operating aerial work platforms. The overall message is the importance of identifying hazards and ensuring proper safety protocols, training and equipment are in place to prevent workplace injuries.