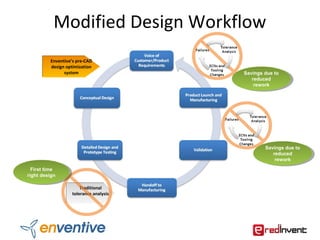

Enventive is a pre-CAD design optimization tool that can optimize mechanical systems before CAD modeling to reduce design iterations, testing prototypes, and costs. It uses equation-based modeling to simulate parameters like forces and tolerances. This allows analysis of design tradeoffs early in the design process. Enventive has been growing rapidly and is used by over 75% of automotive companies to streamline product development.