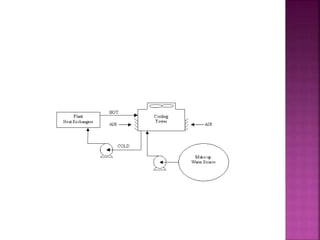

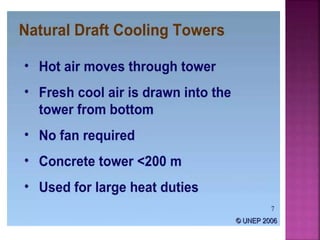

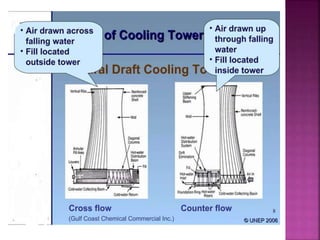

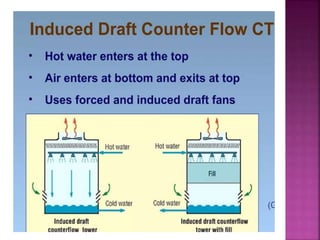

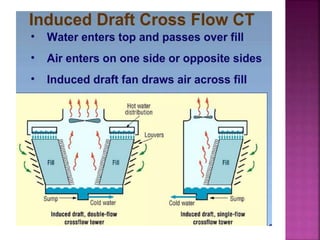

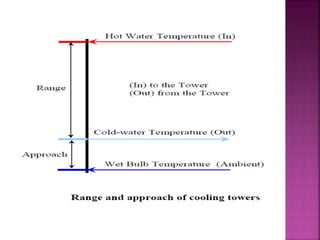

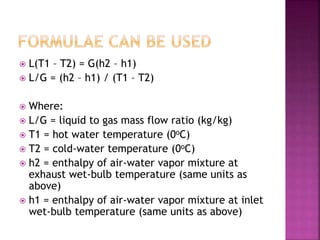

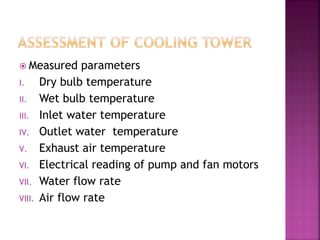

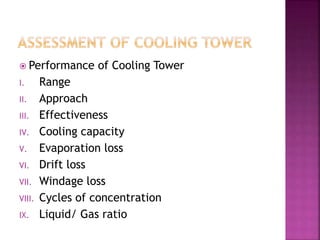

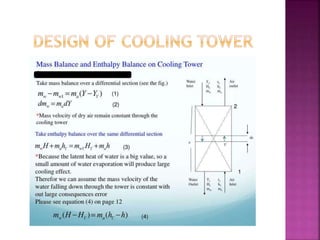

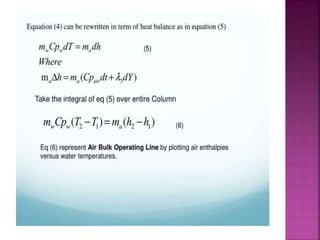

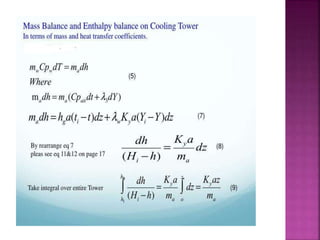

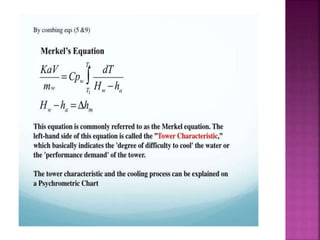

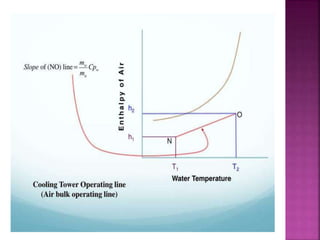

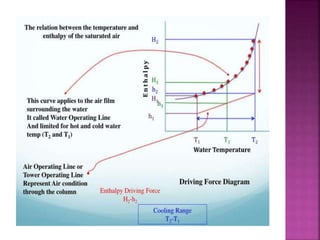

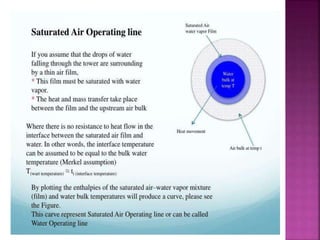

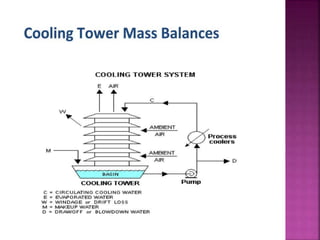

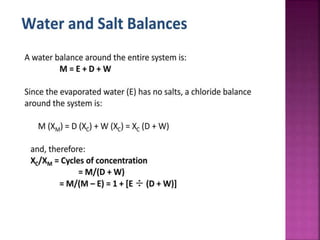

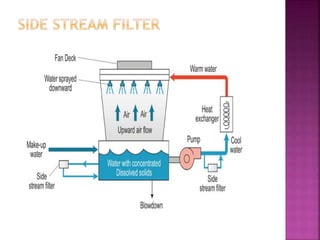

This document discusses cooling towers. It begins by explaining that cooling towers are used to reject heat from cooling water by sending hot water through the tower and returning cooler water. It then covers the components of cooling towers, key terms like range and approach, how they work using psychrometric charts, design considerations, and parameters for measuring performance like temperature and flow rates. Routine maintenance is also discussed, like blowdown to control scale buildup and using inhibitors and filters.