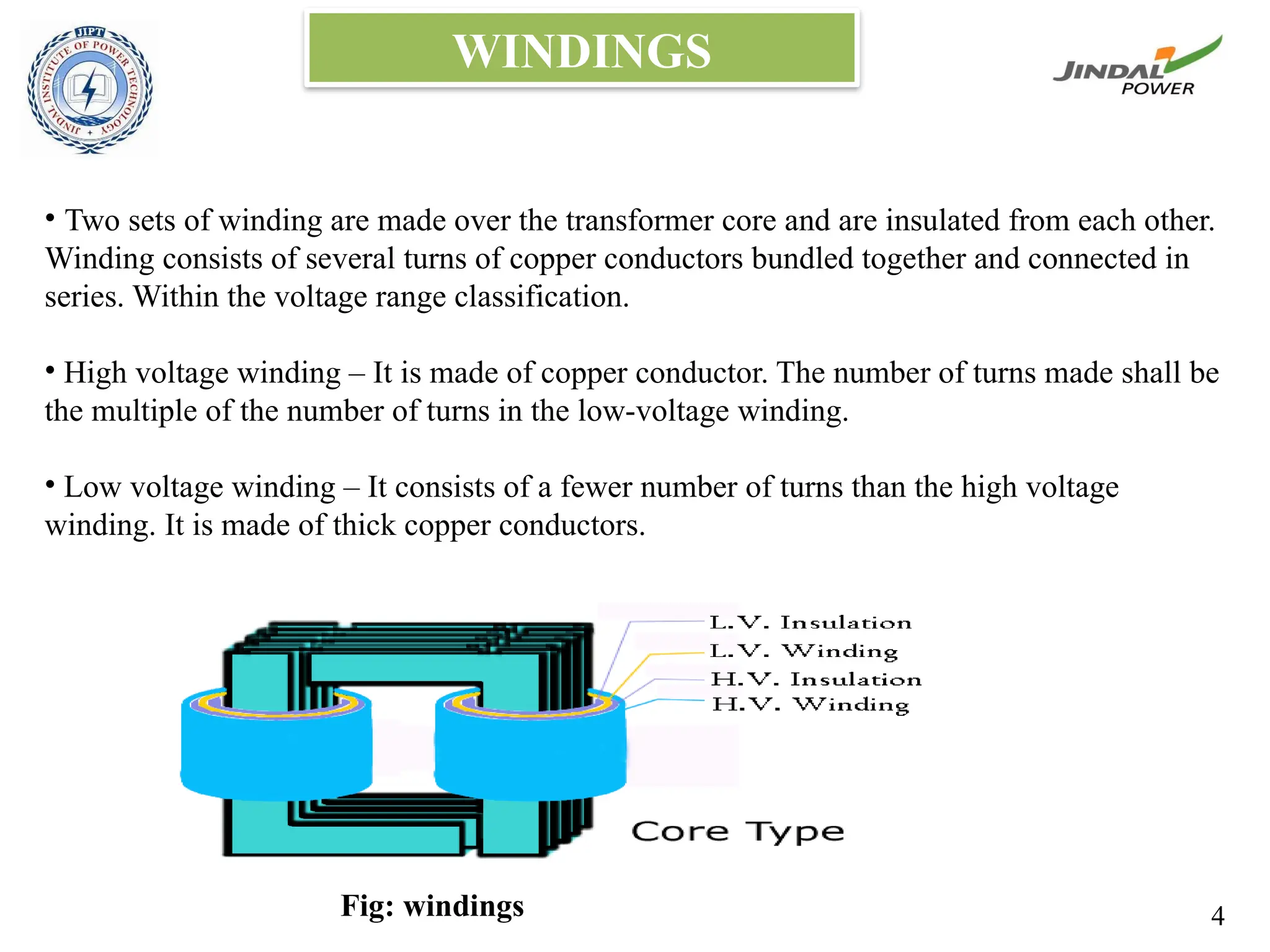

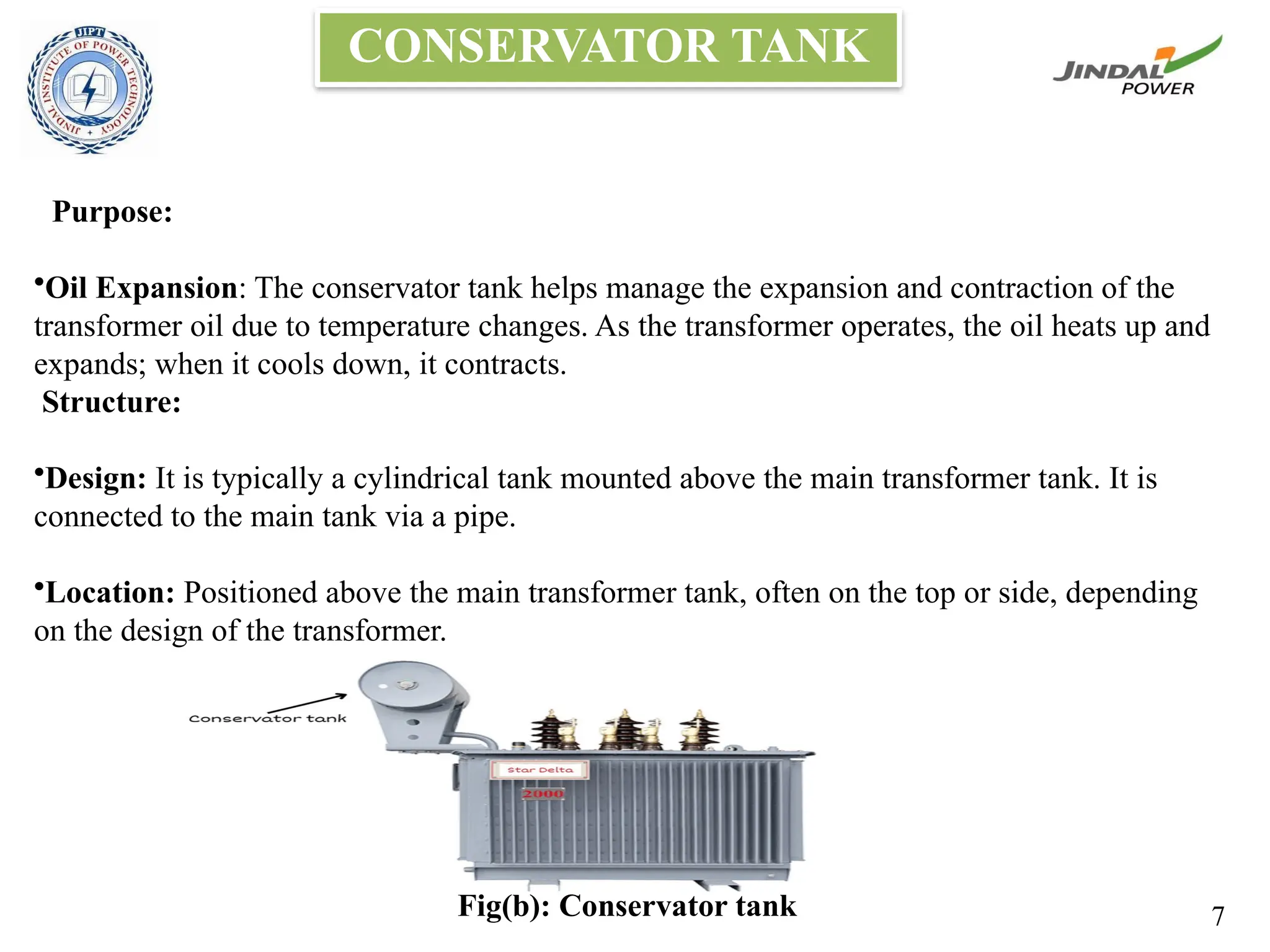

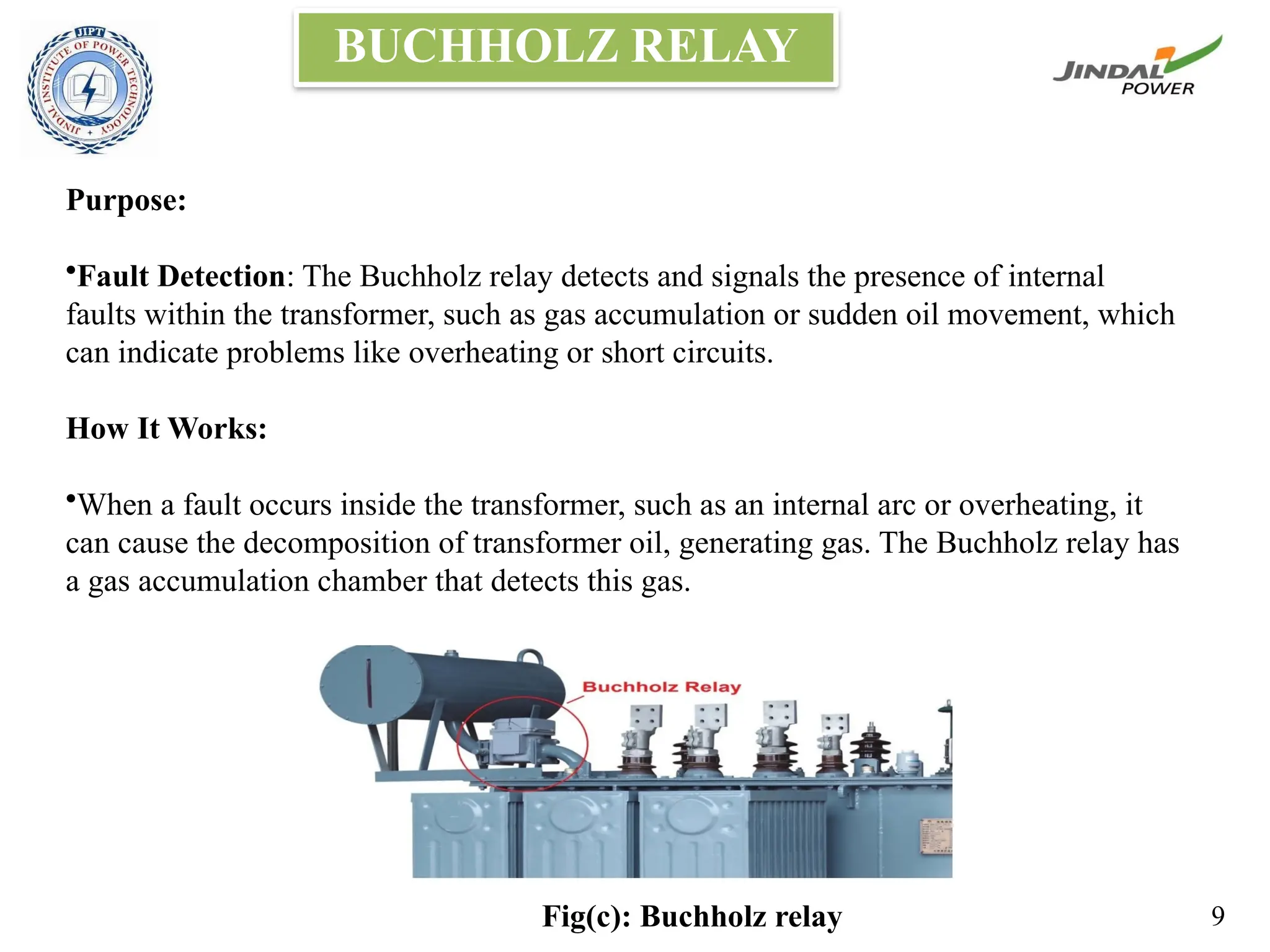

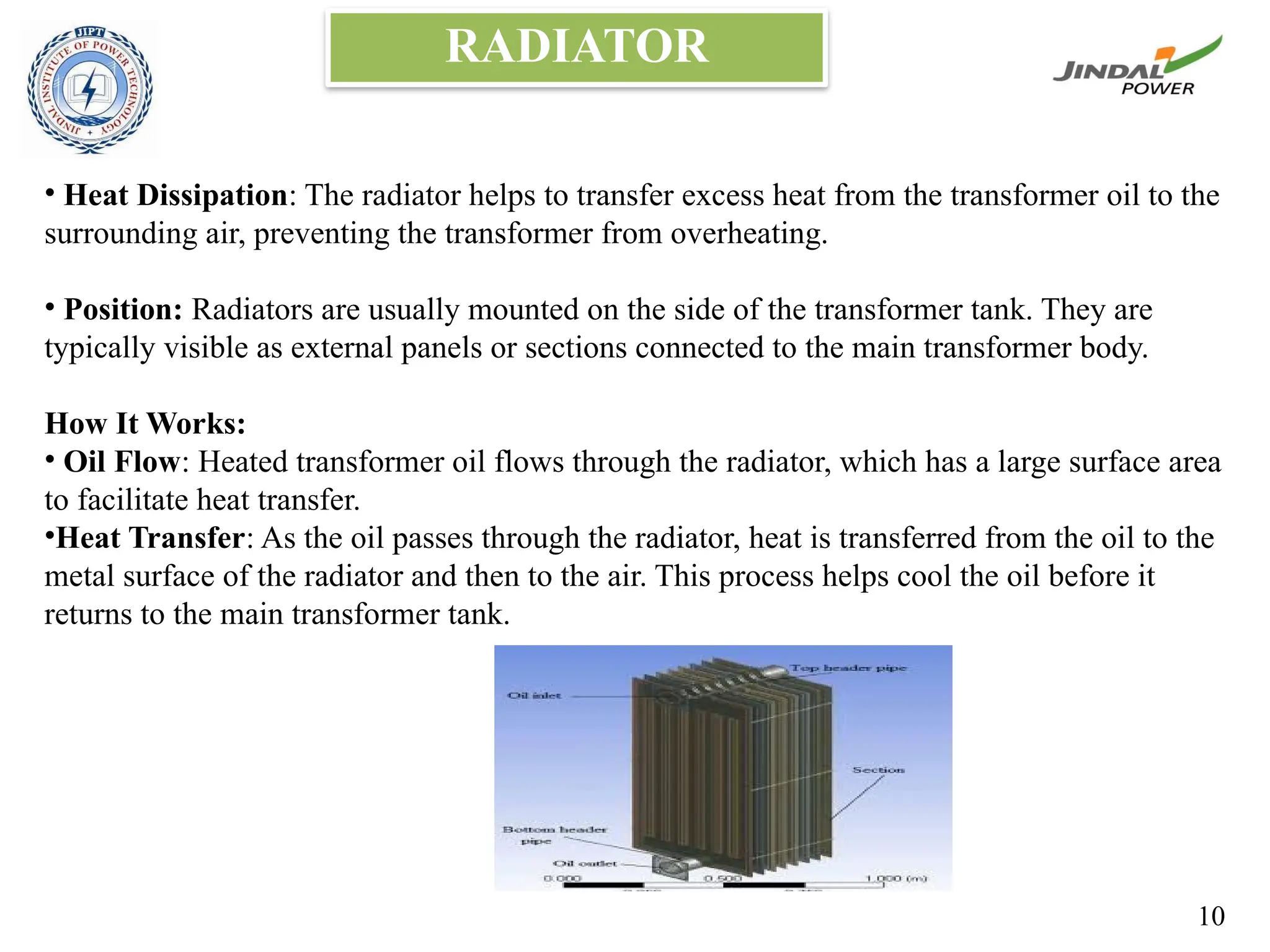

The document is a presentation on transformers, detailing their parts, functions, and advantages. Key components include the laminated core, windings, insulating materials, transformer oil, conservator tank, breather, buchholz relay, radiator, bushing, and explosion vent, each with specific roles in electrical energy transfer and safety. The conclusion highlights that transformers operate on the principles of electromagnetic induction to change voltage levels within AC circuits.