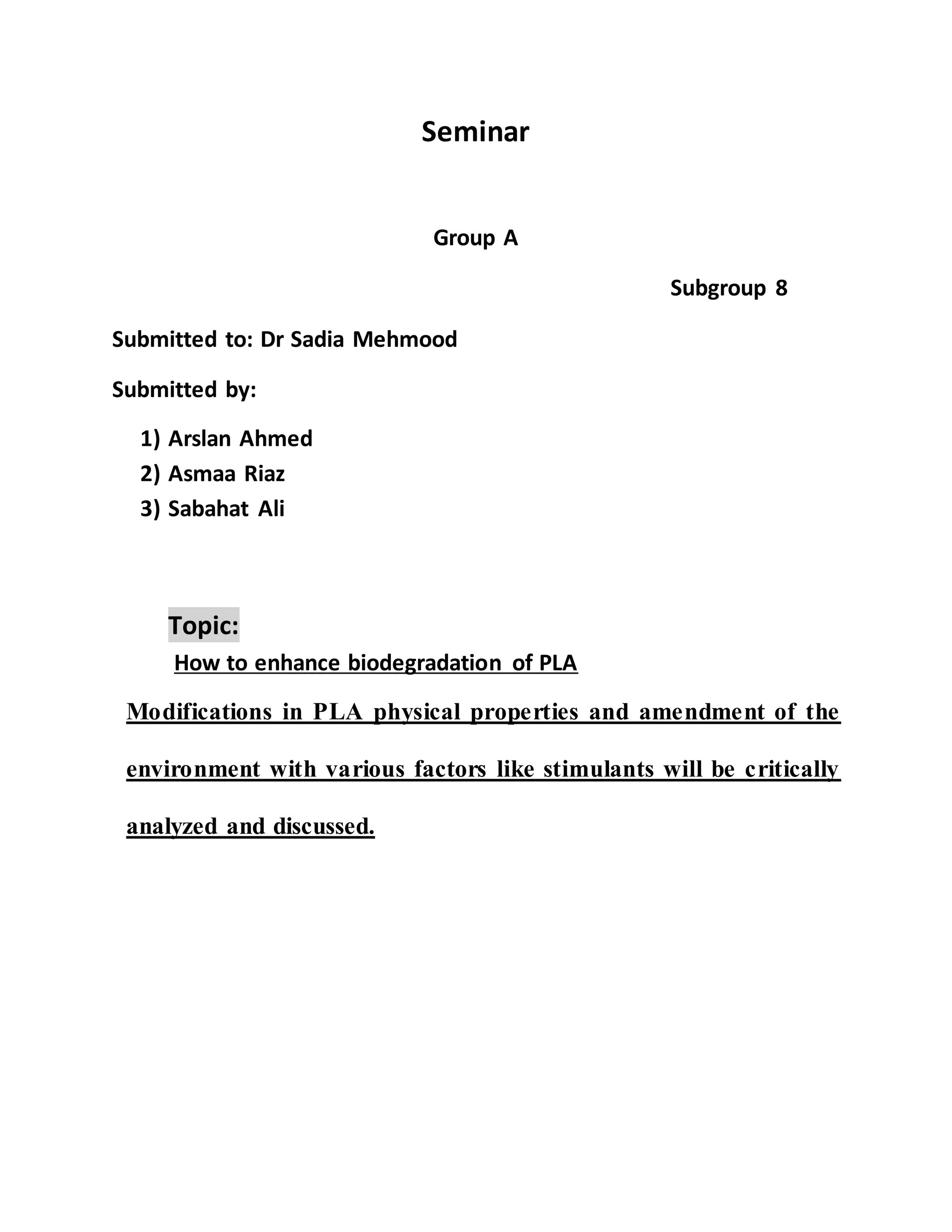

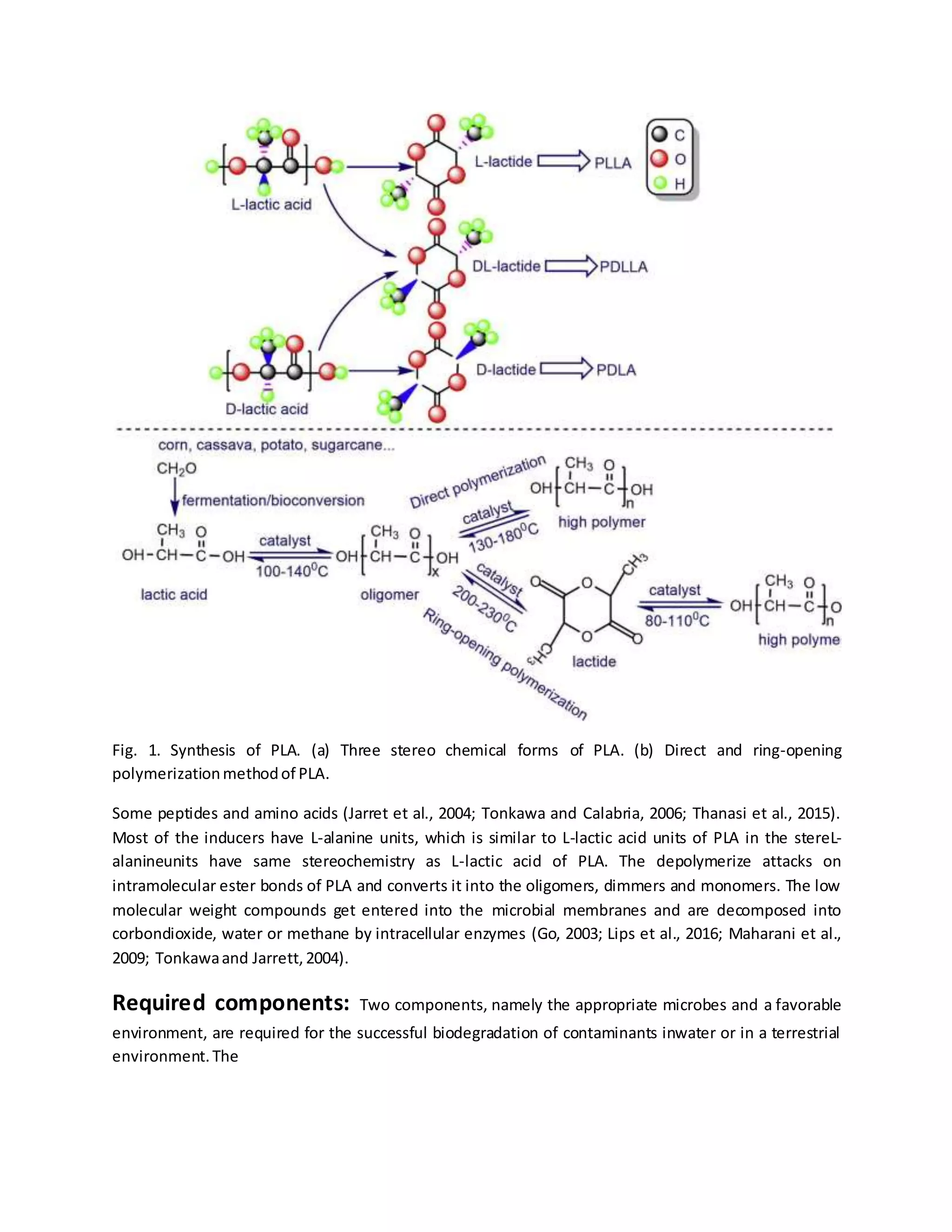

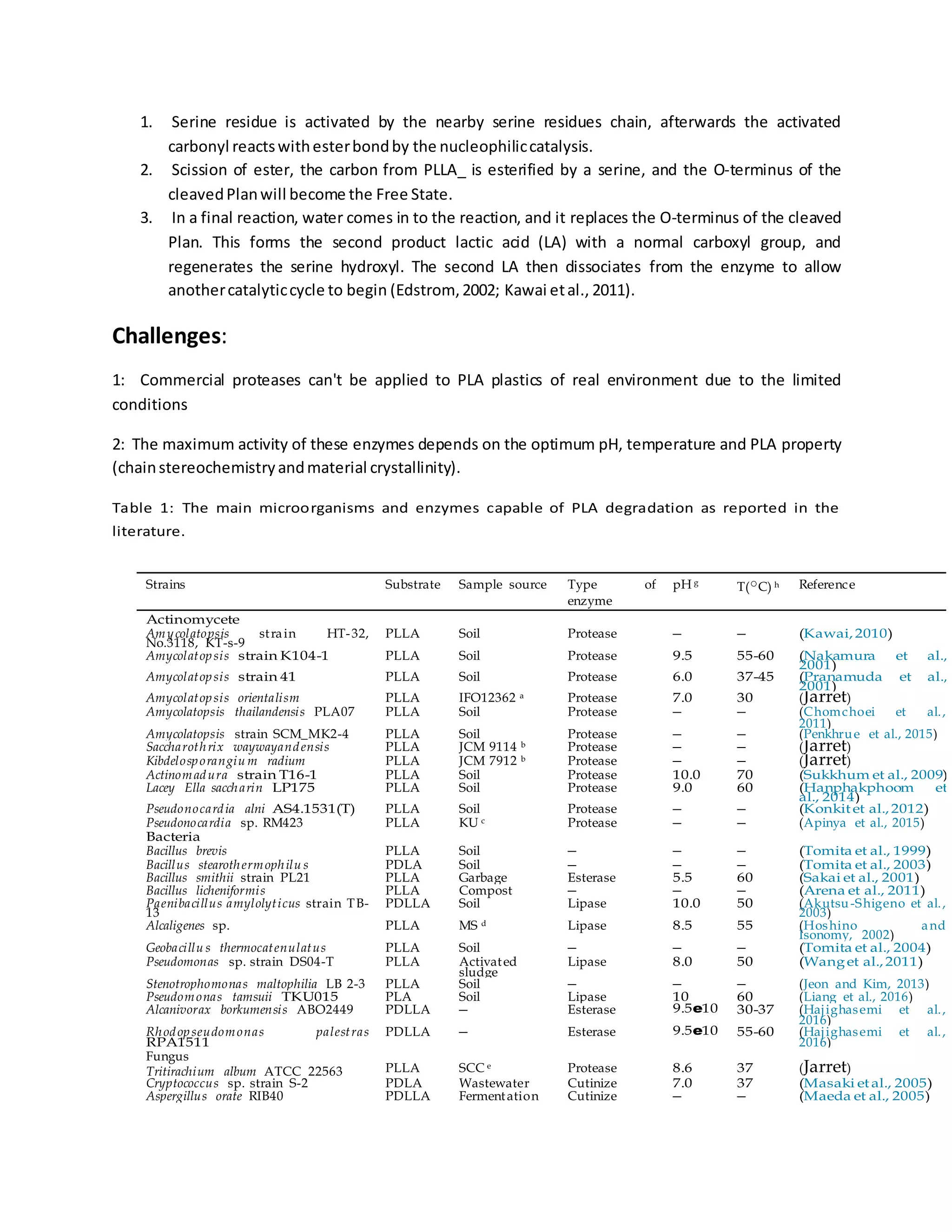

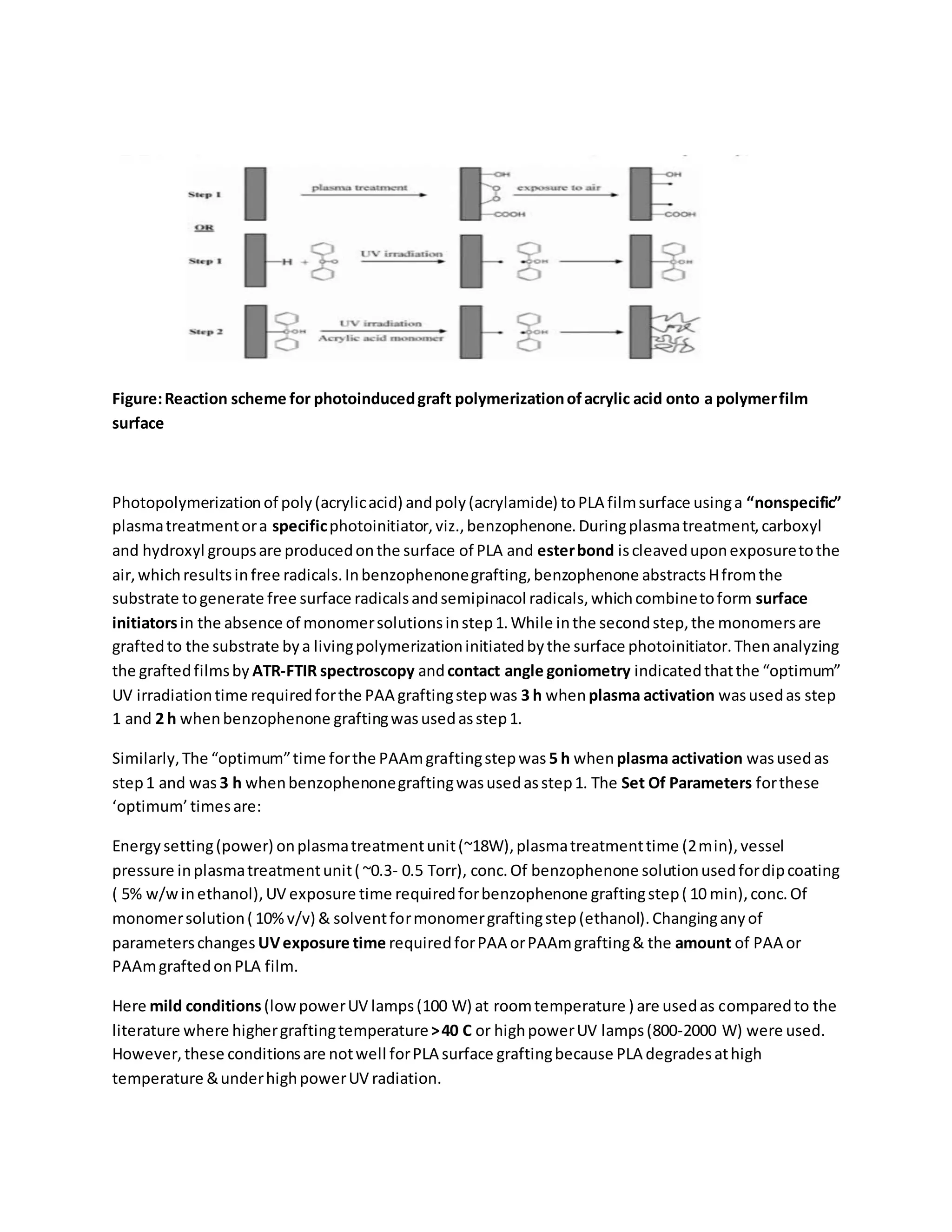

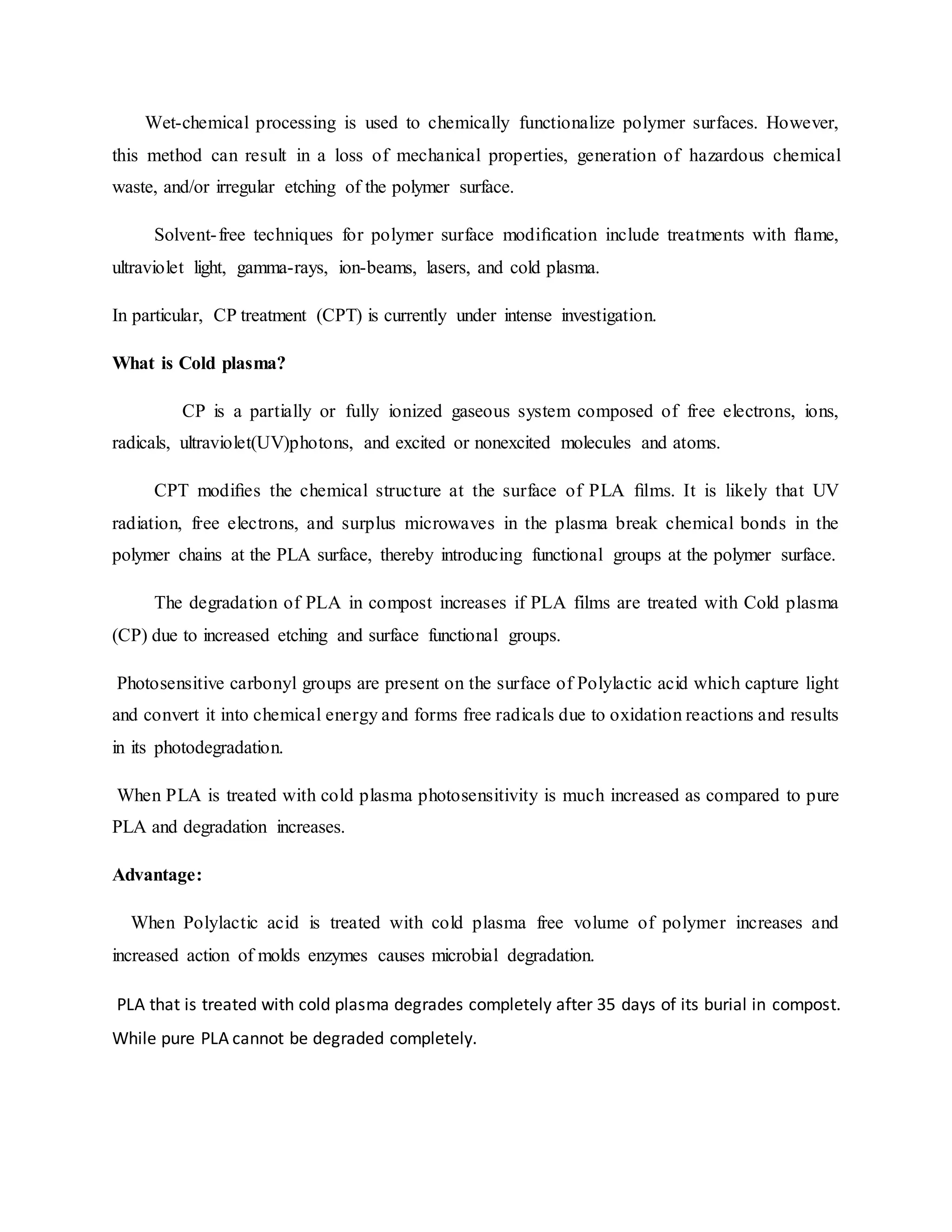

The document discusses methods to enhance the biodegradation of polylactic acid (PLA). It analyzes modifications to PLA's physical properties and amending the environment with various factors like stimulants. It summarizes that biodegradation of PLA mainly occurs through hydrolysis of ester bonds and is induced by microorganisms like certain actinomycetes, bacteria, and fungi. Key factors like temperature, pH, humidity, and oxygen levels also affect the degradation rate. While PLA is biodegradable, the process is often slow under natural conditions.