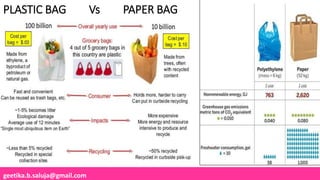

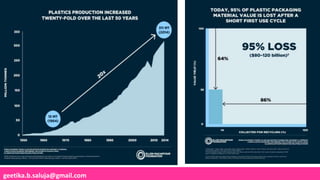

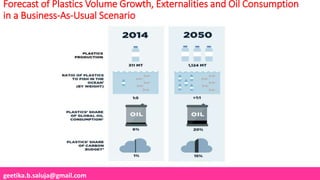

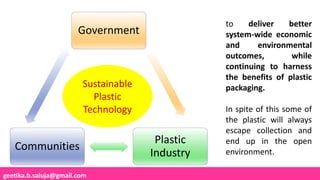

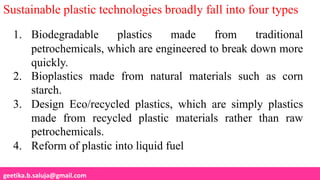

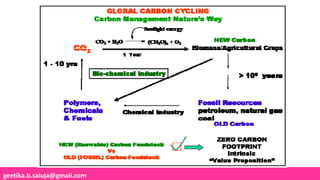

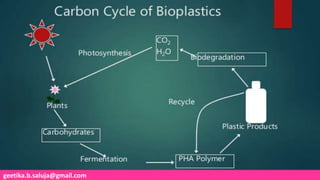

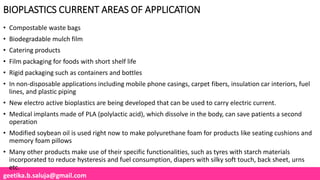

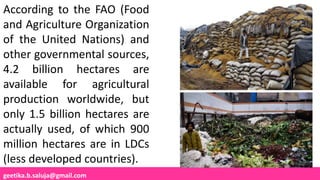

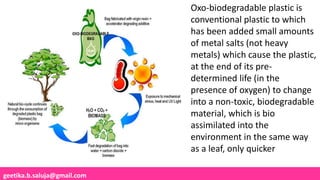

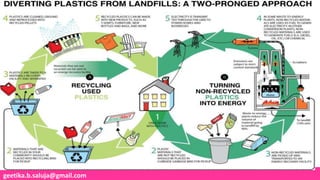

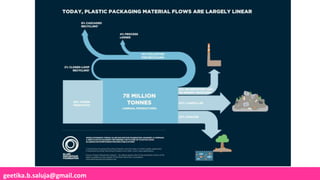

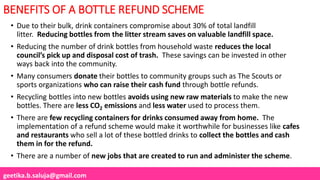

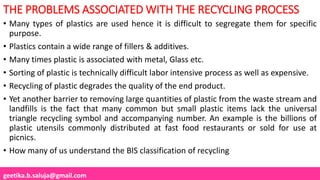

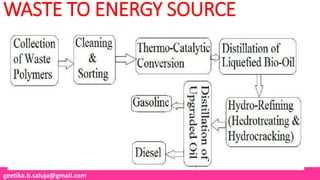

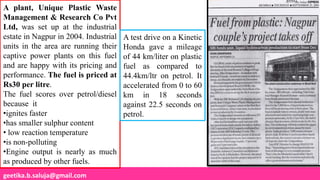

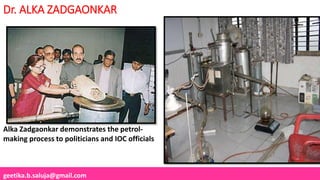

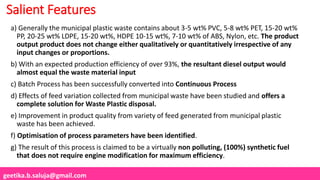

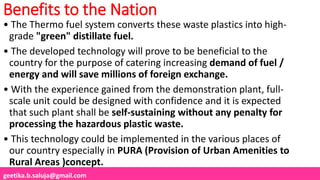

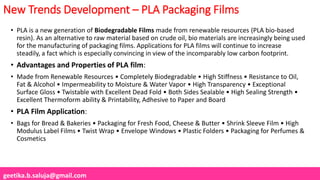

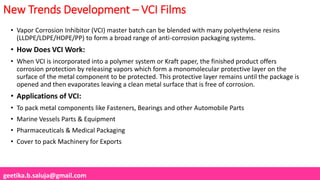

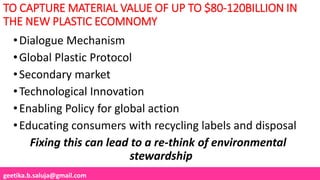

The document discusses different approaches to making plastics more sustainable, including using sustainable plastic technologies in packaging, regulating end-of-life plastics, and commercializing recycling. It addresses bioplastics and biodegradable plastics as alternatives, challenges with plastic waste, and the benefits of recycling to reduce environmental impacts.