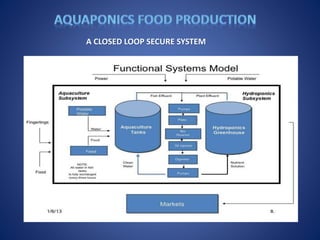

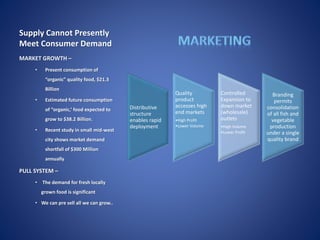

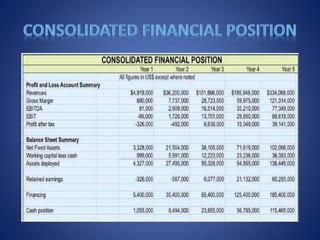

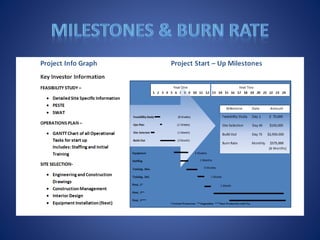

This document presents a business plan for an aquaponics startup called the Family Fish Farms Network. The plan outlines the company's mission to address demand for locally grown food through aquaponics farms, introducing an innovative and sustainable business model. Key points include micro-franchising aquaponics systems nationally, producing a variety of fish and vegetables, achieving positive cash flow within 18 months, and creating over 200 new green jobs.