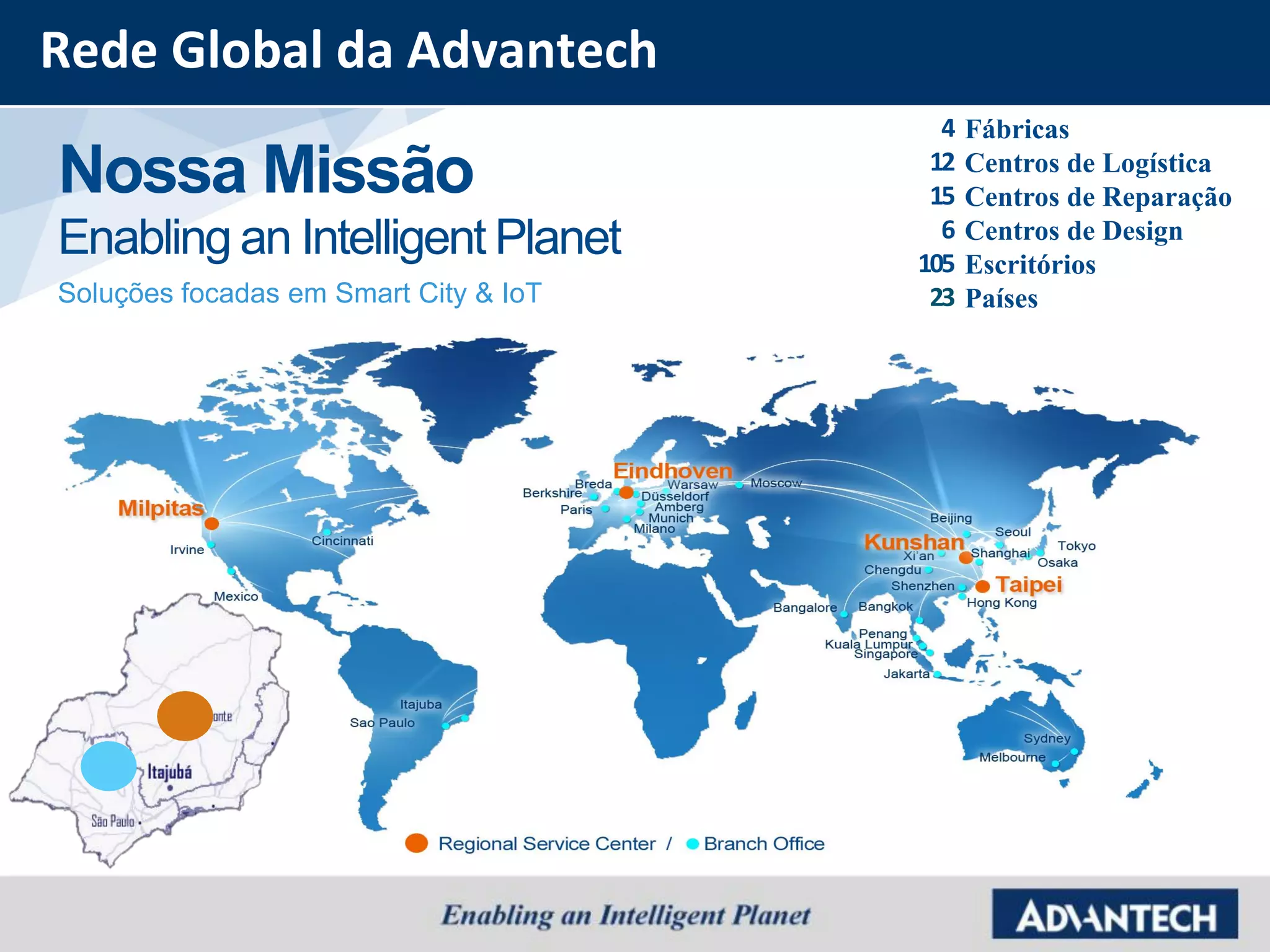

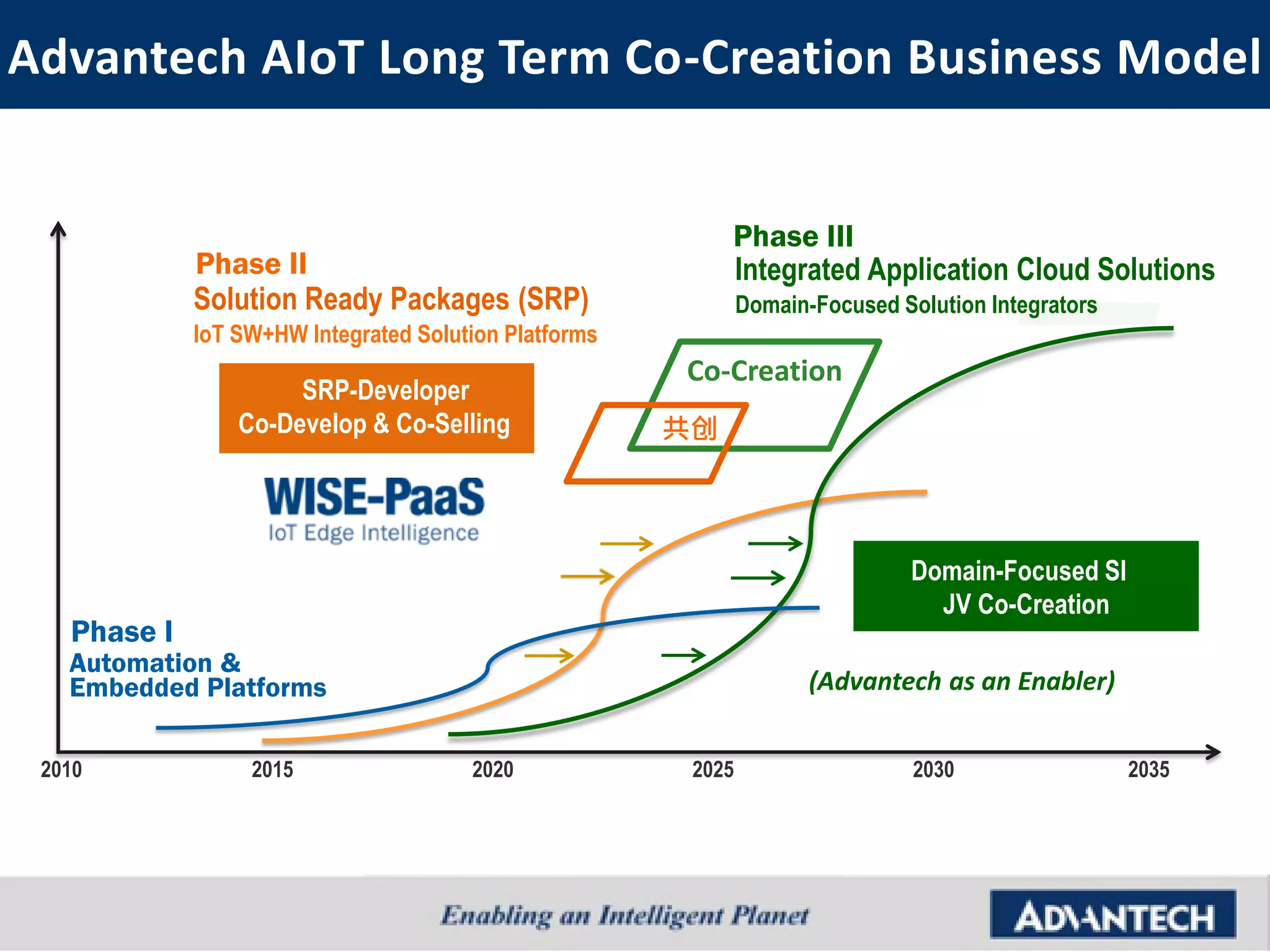

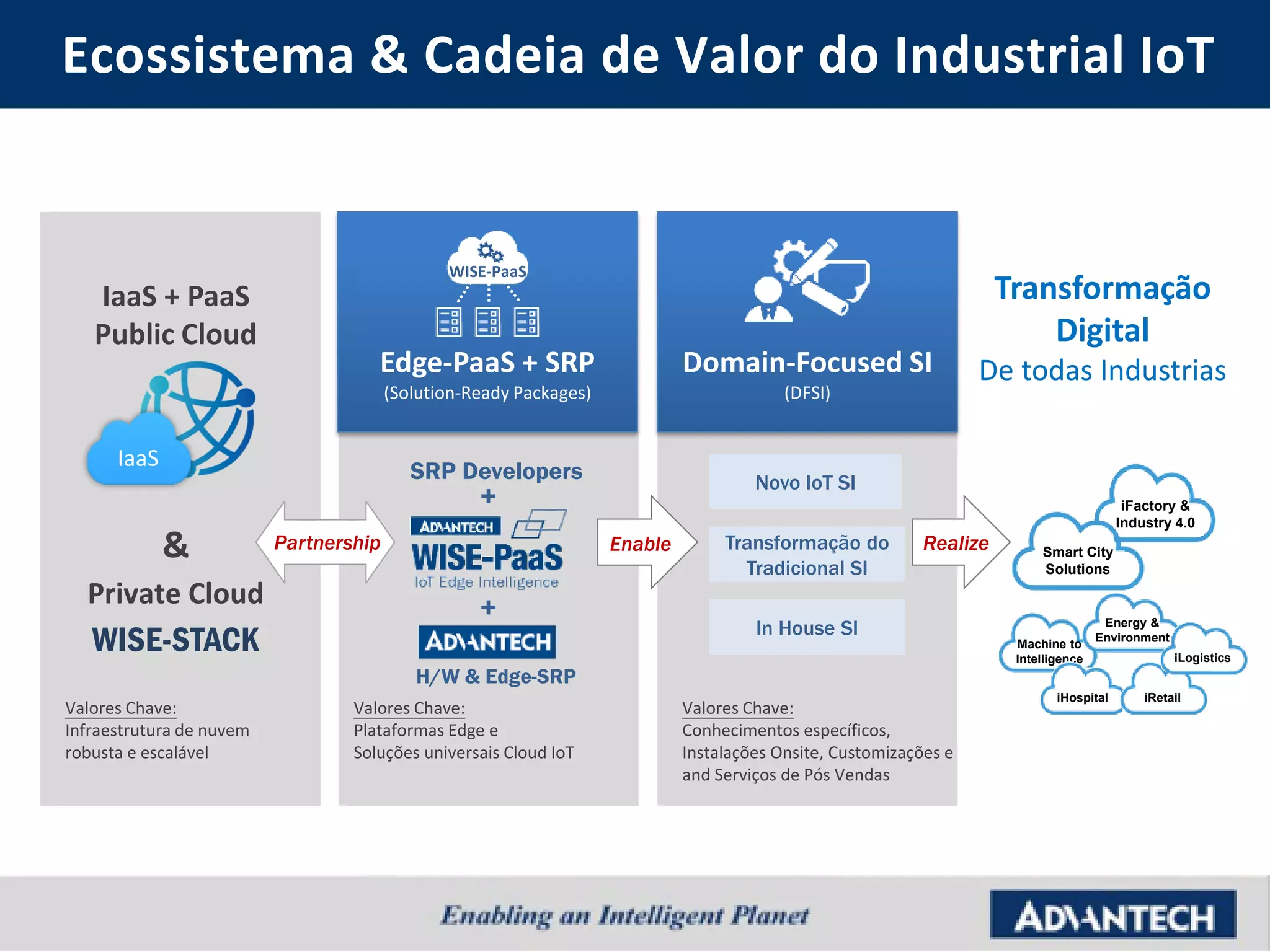

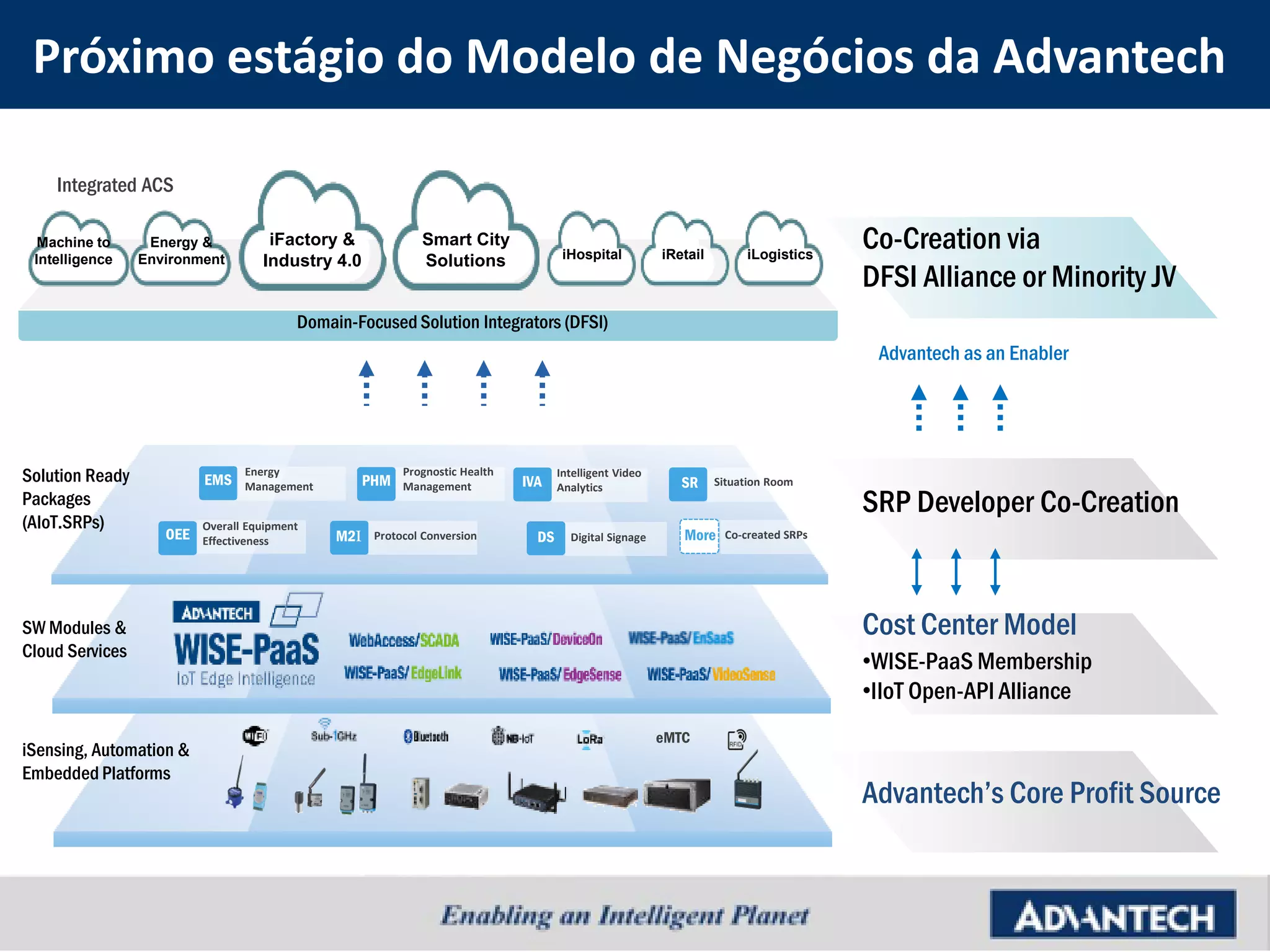

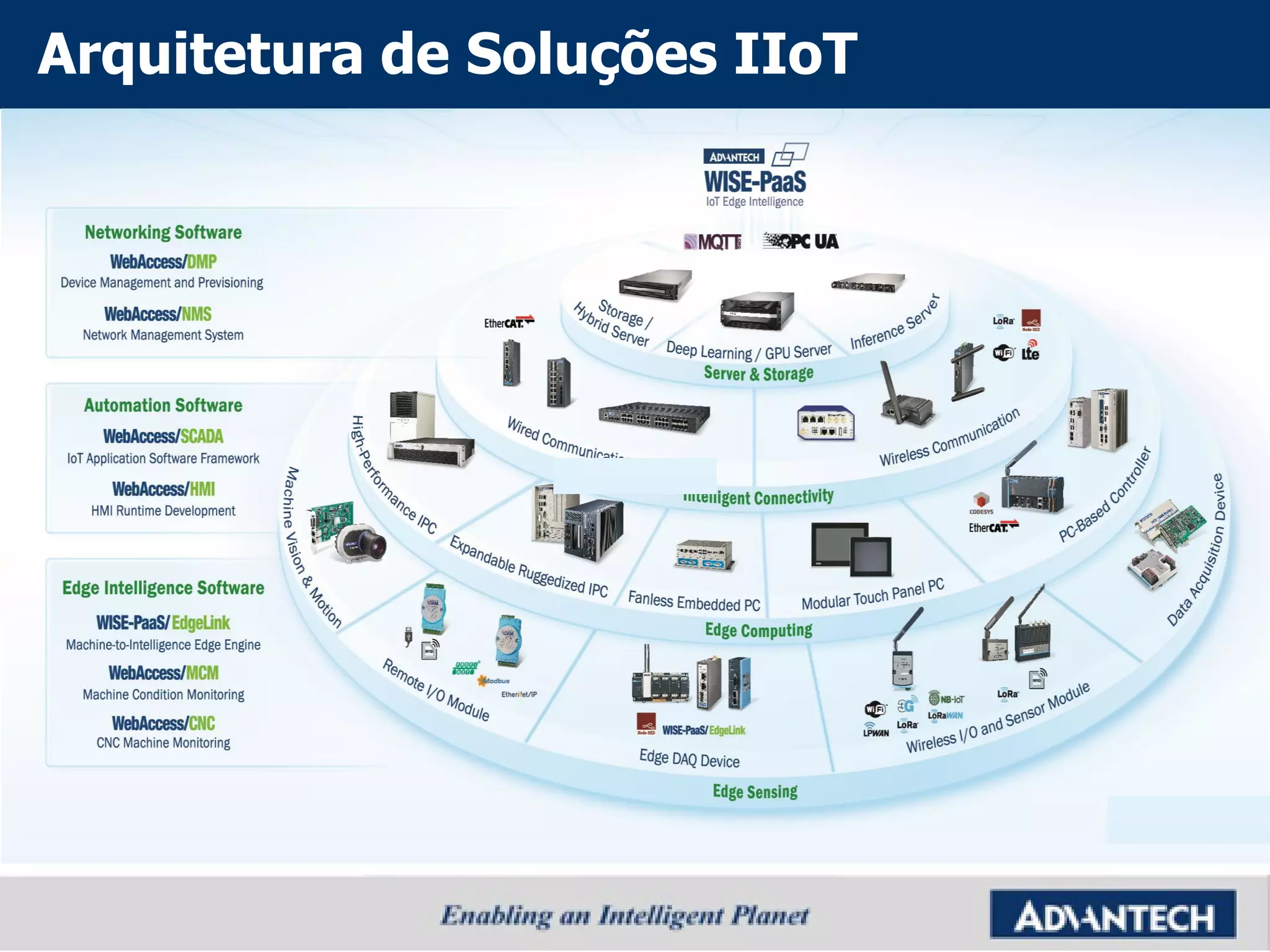

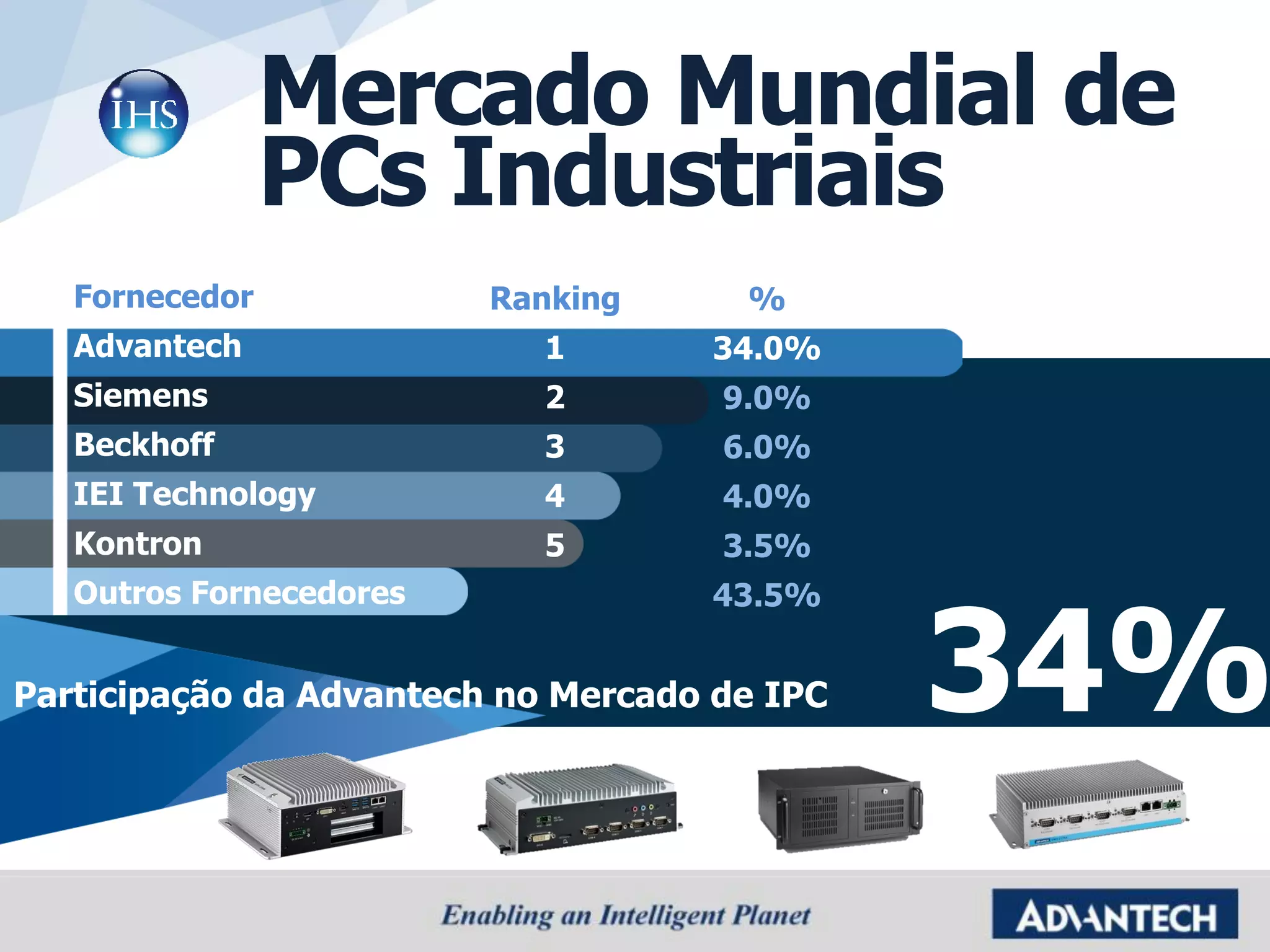

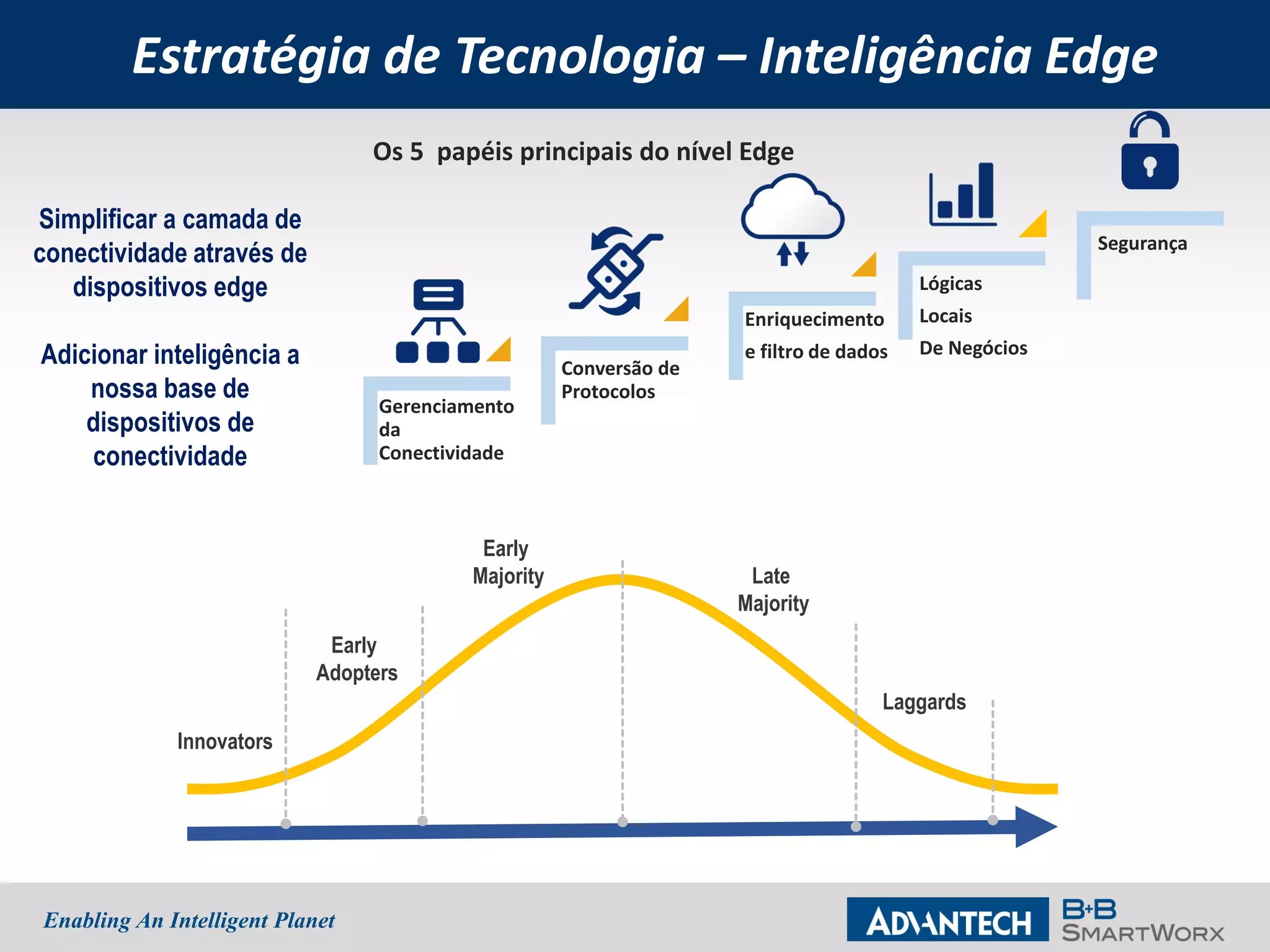

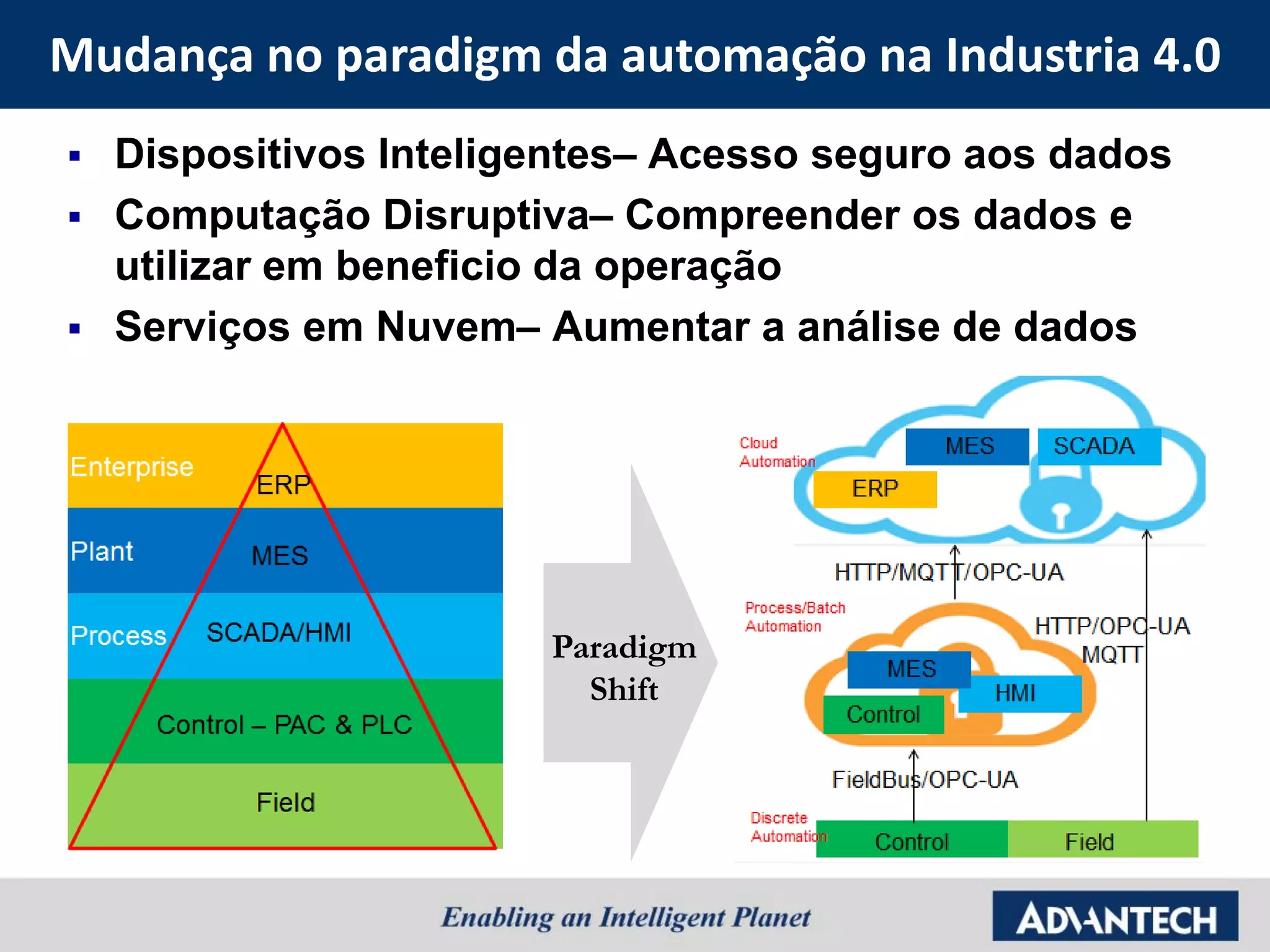

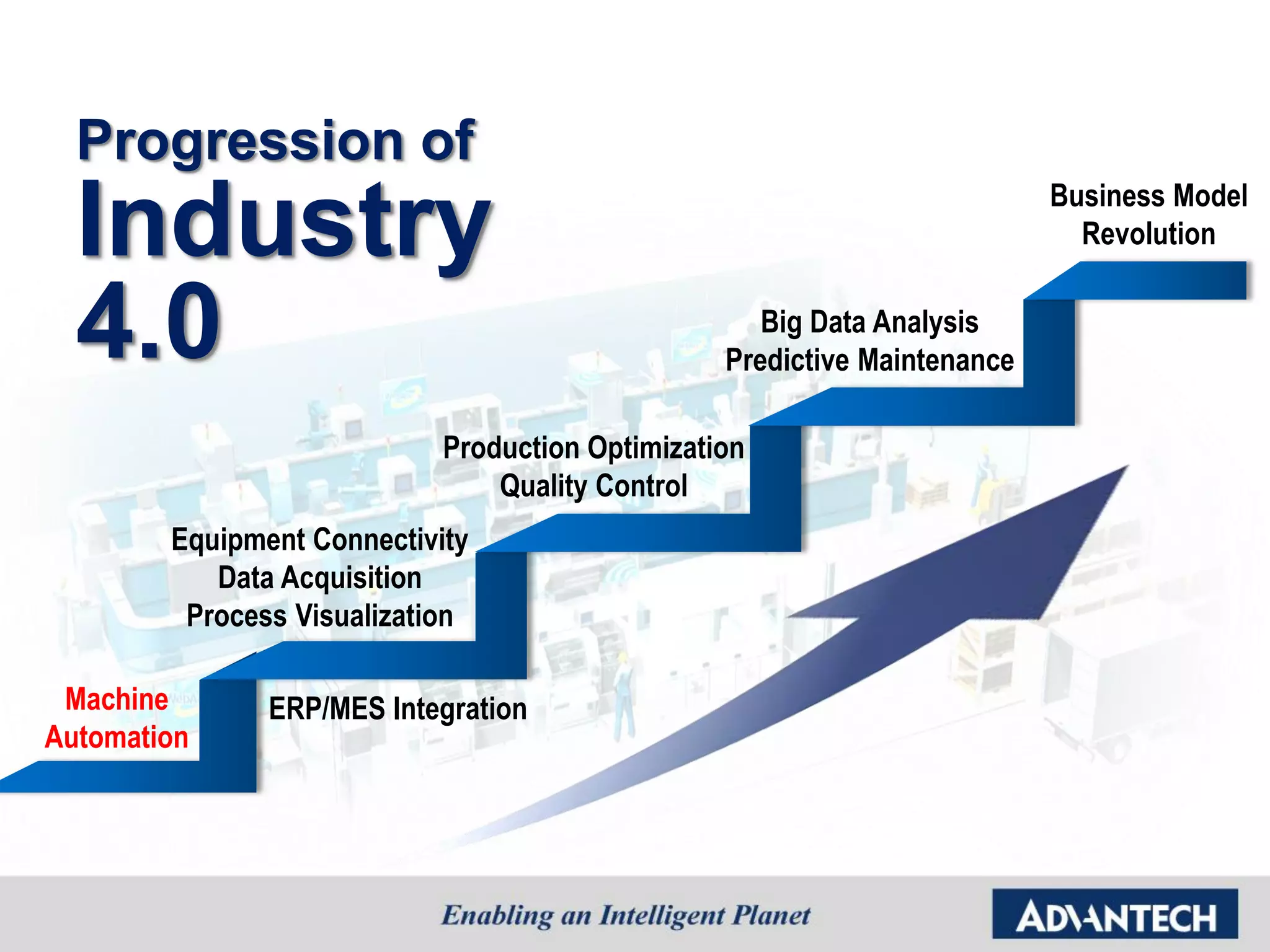

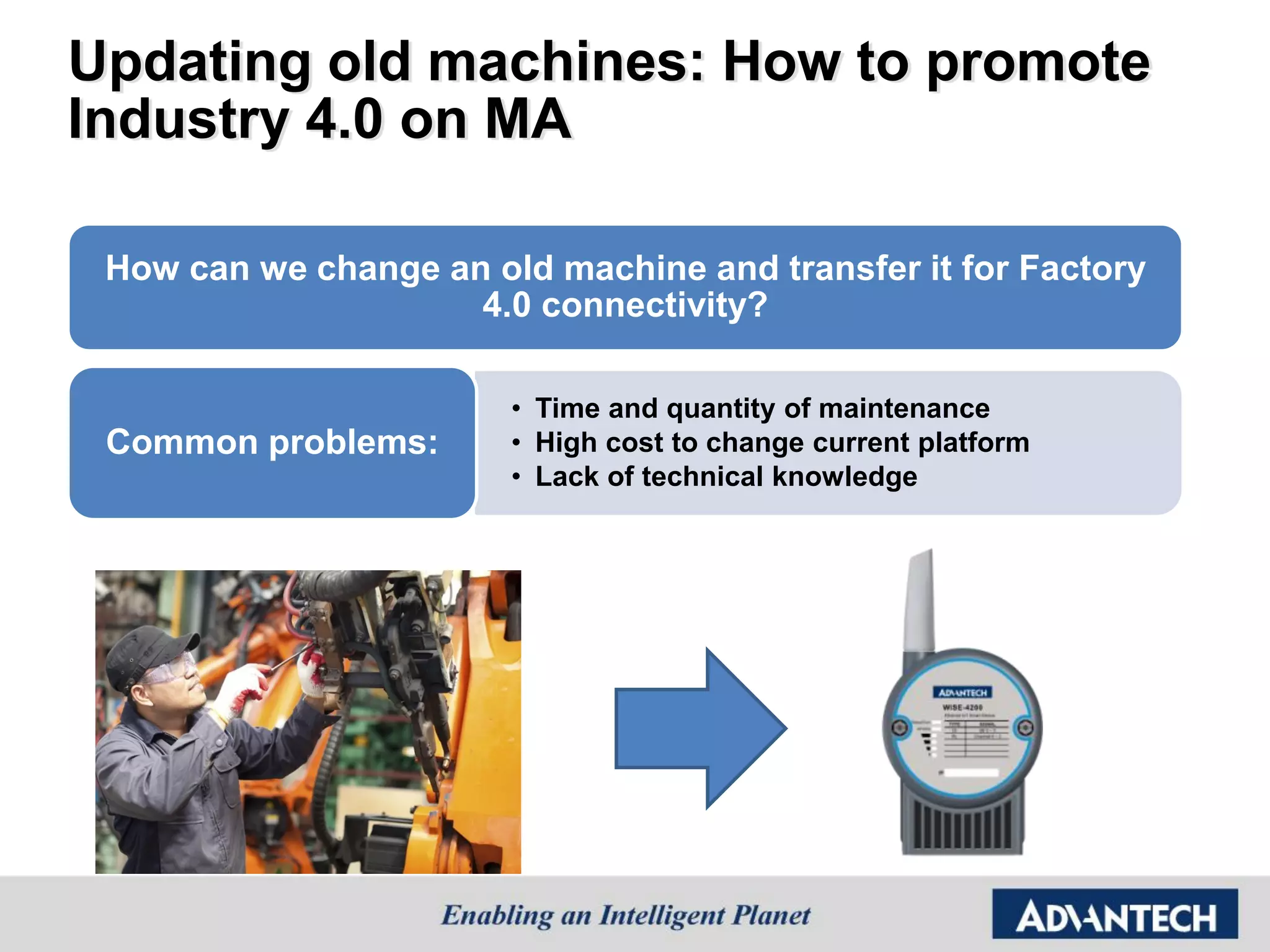

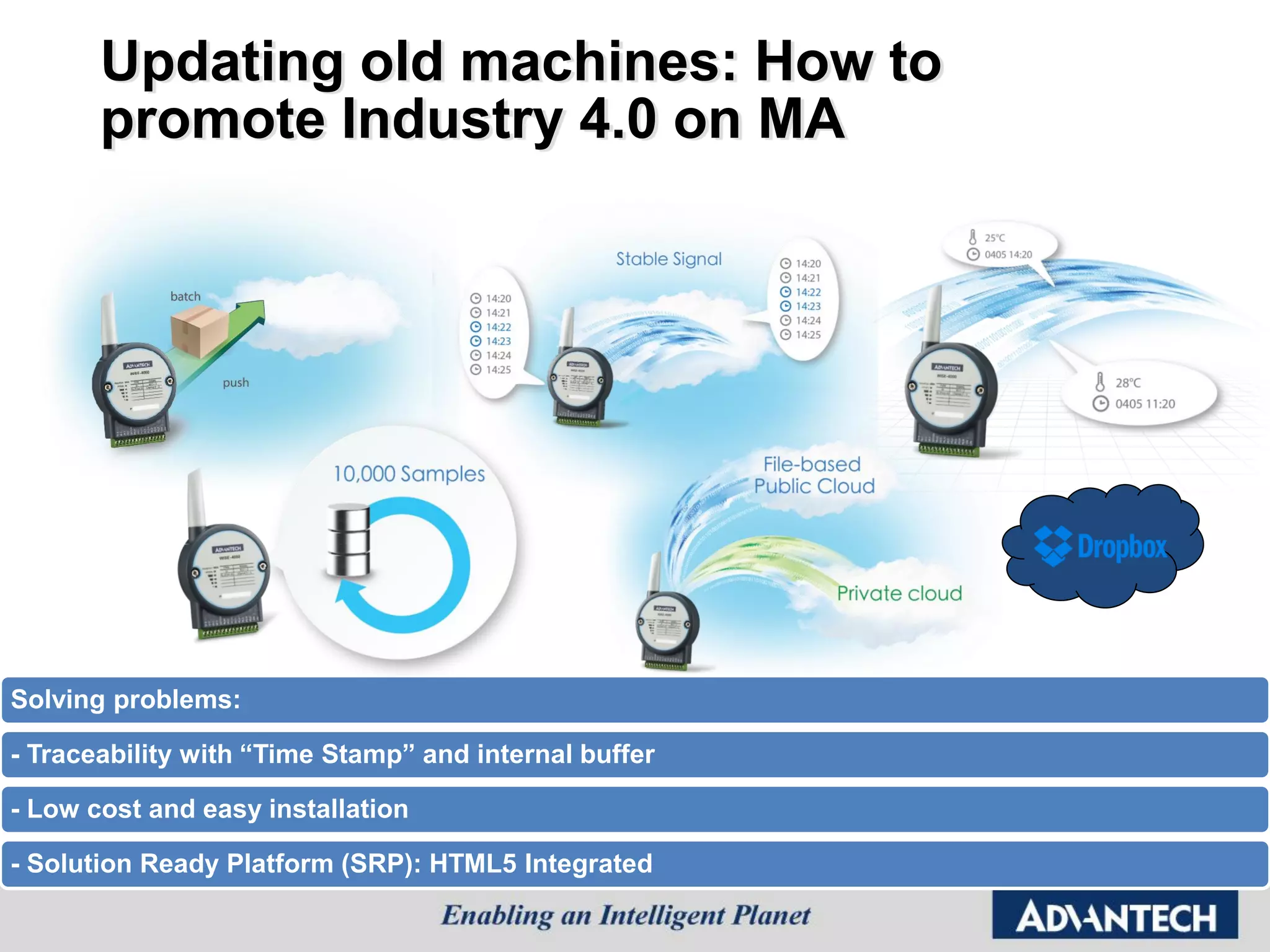

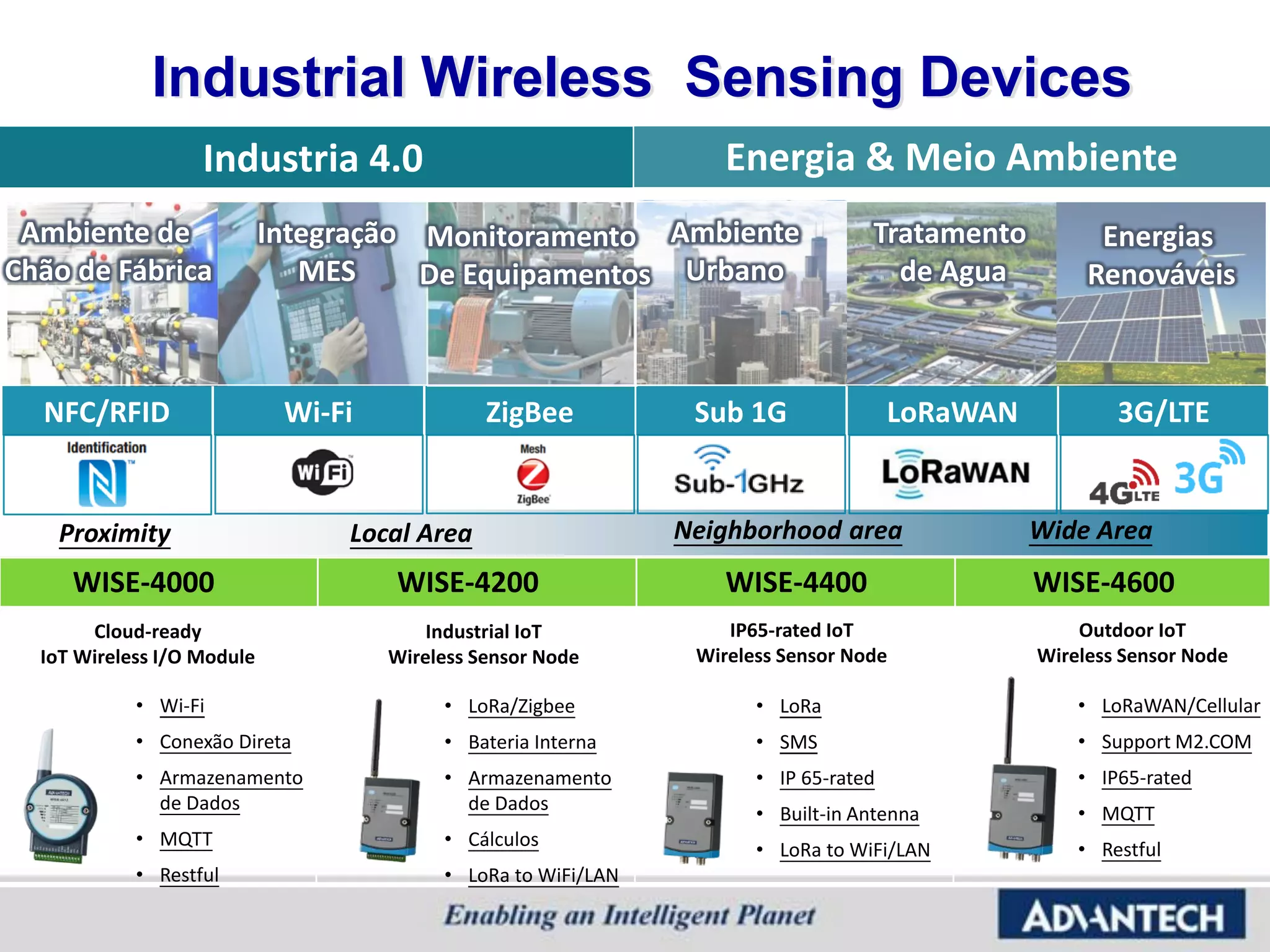

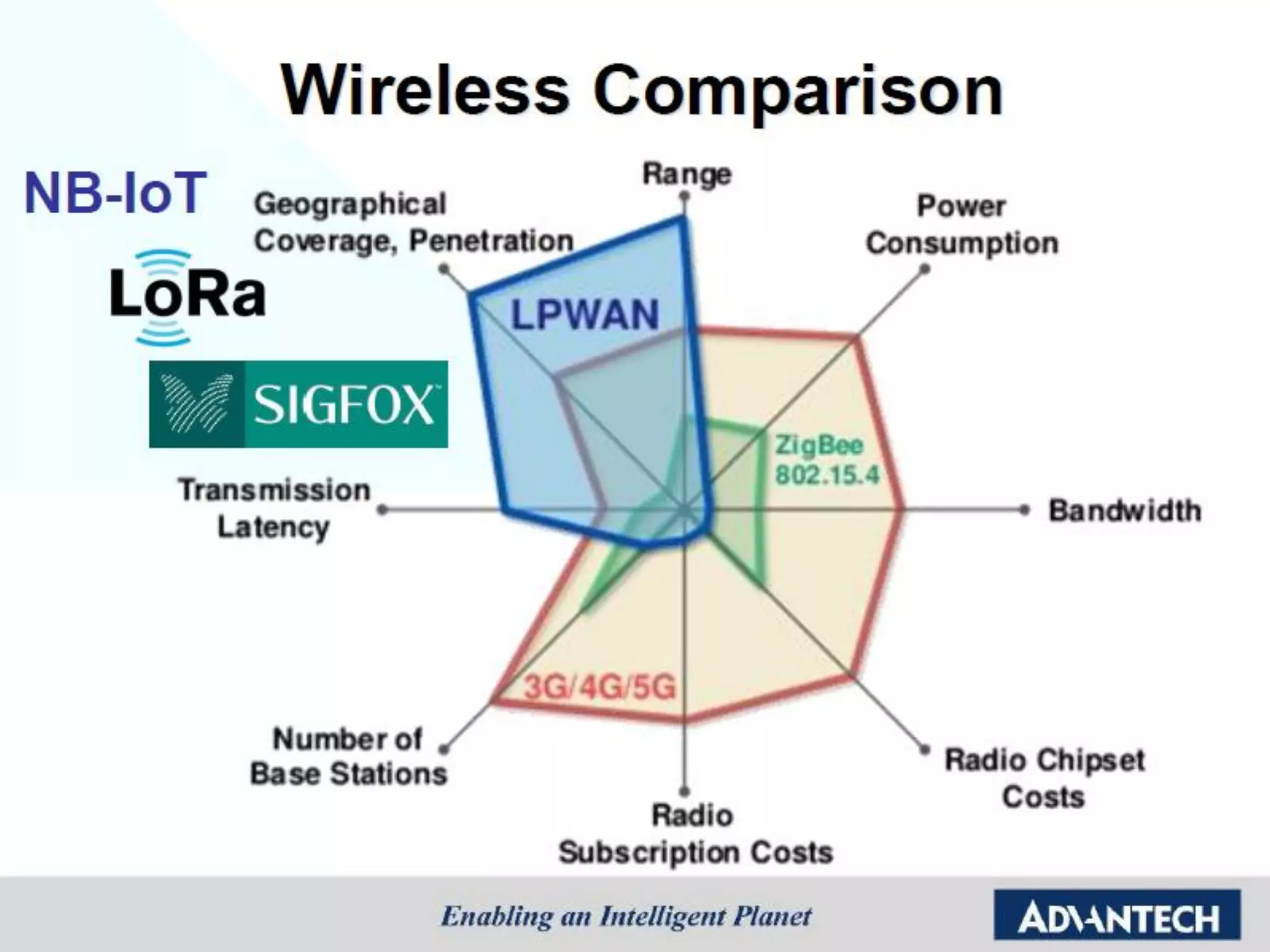

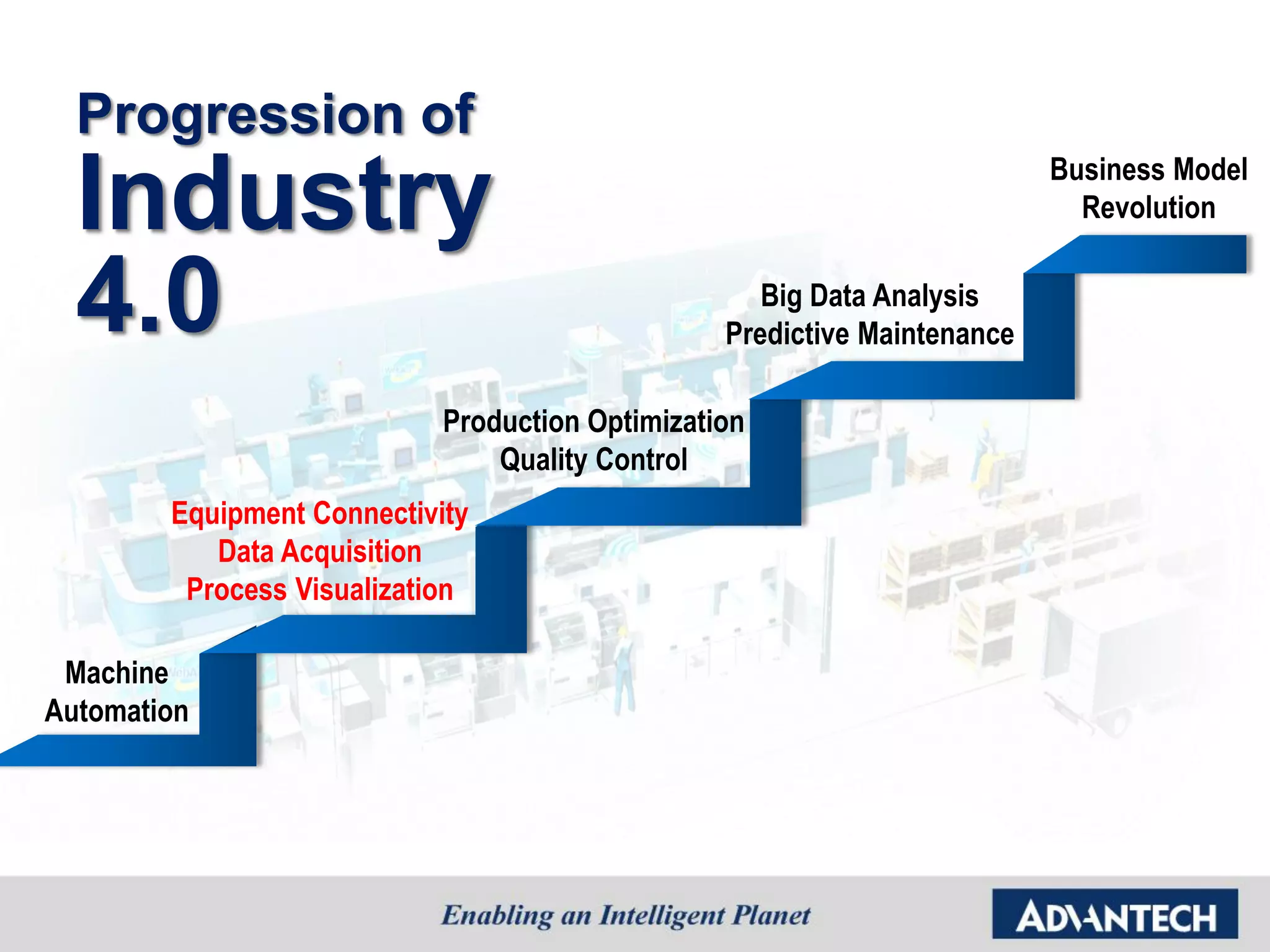

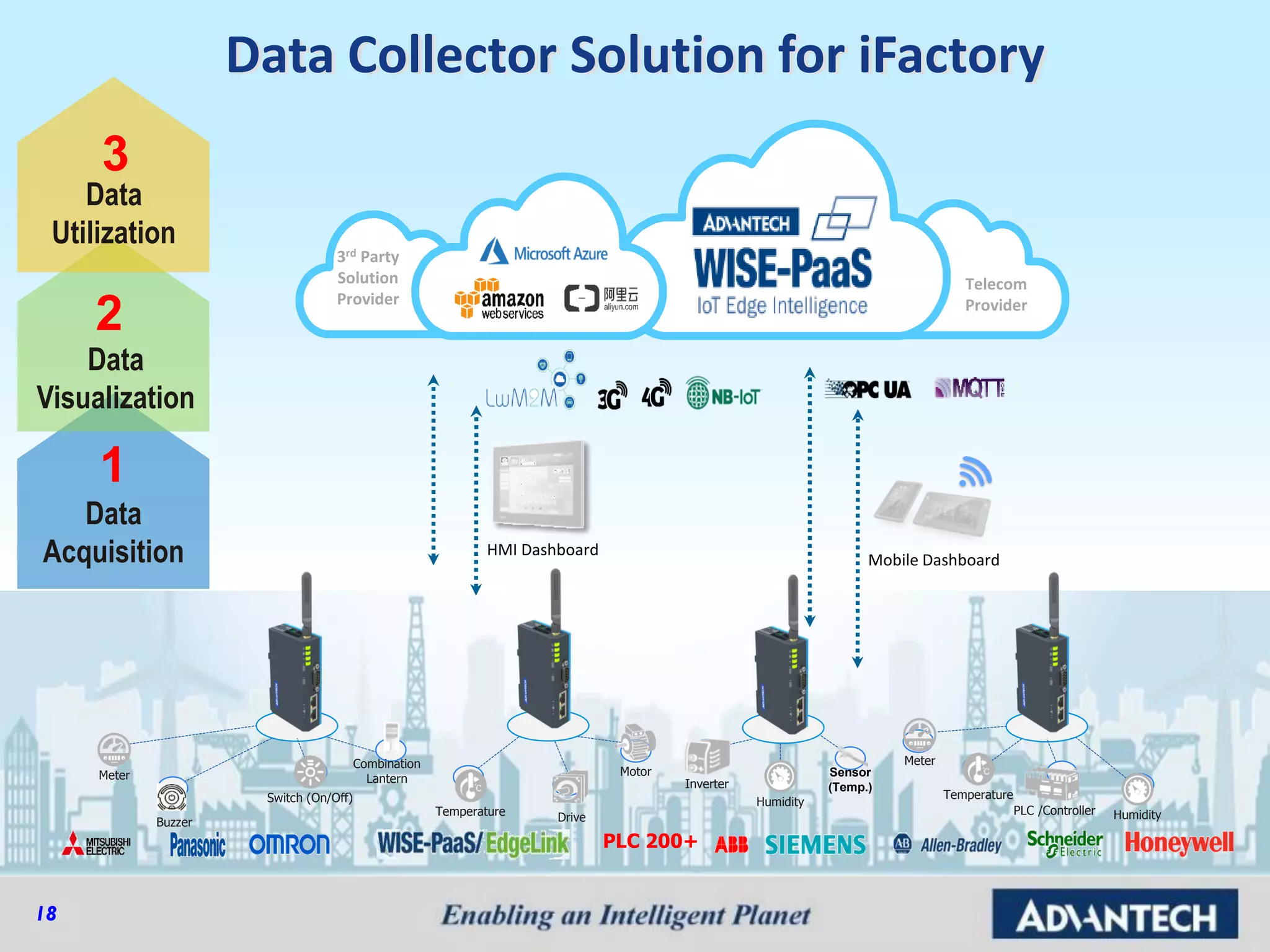

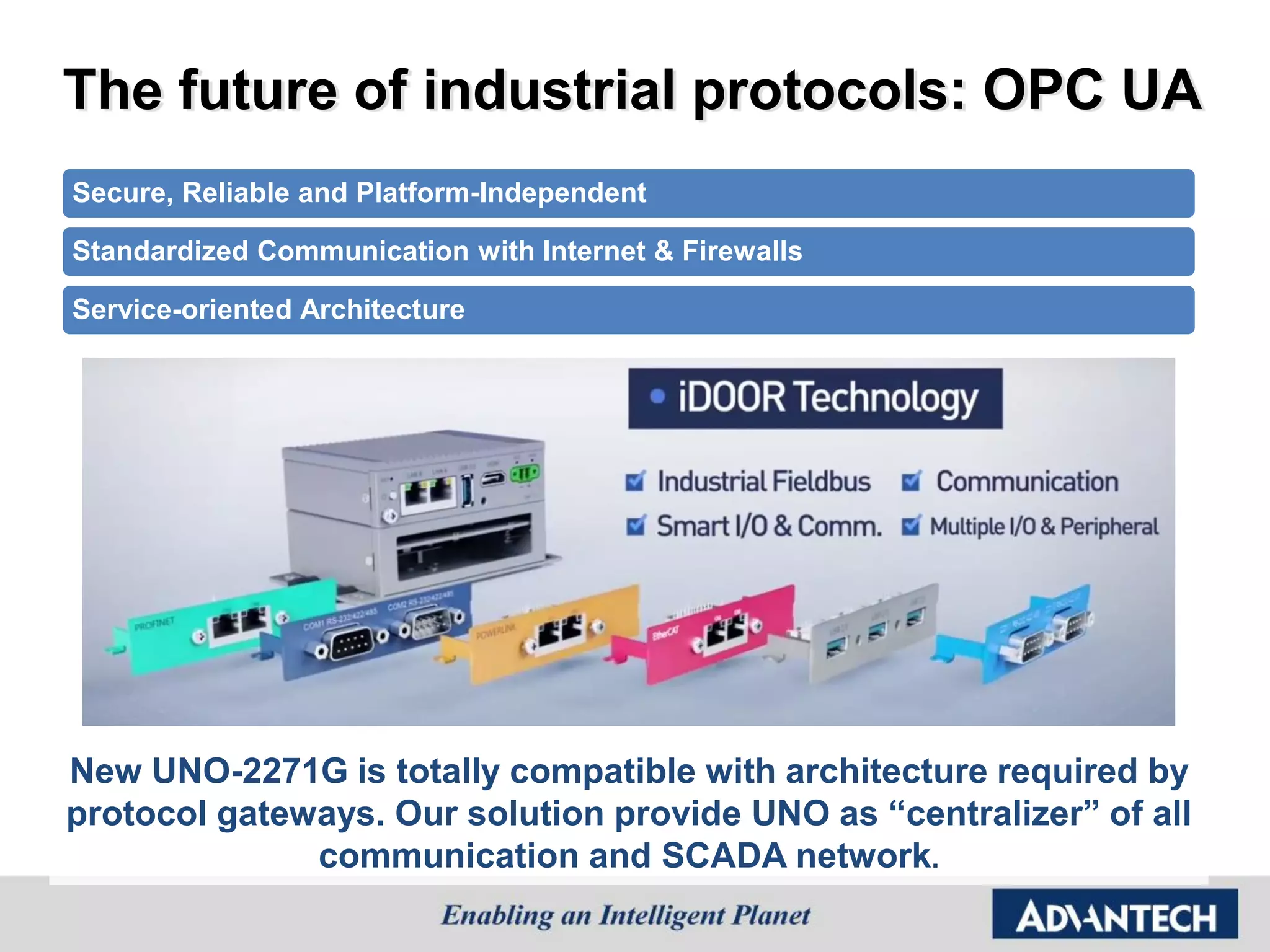

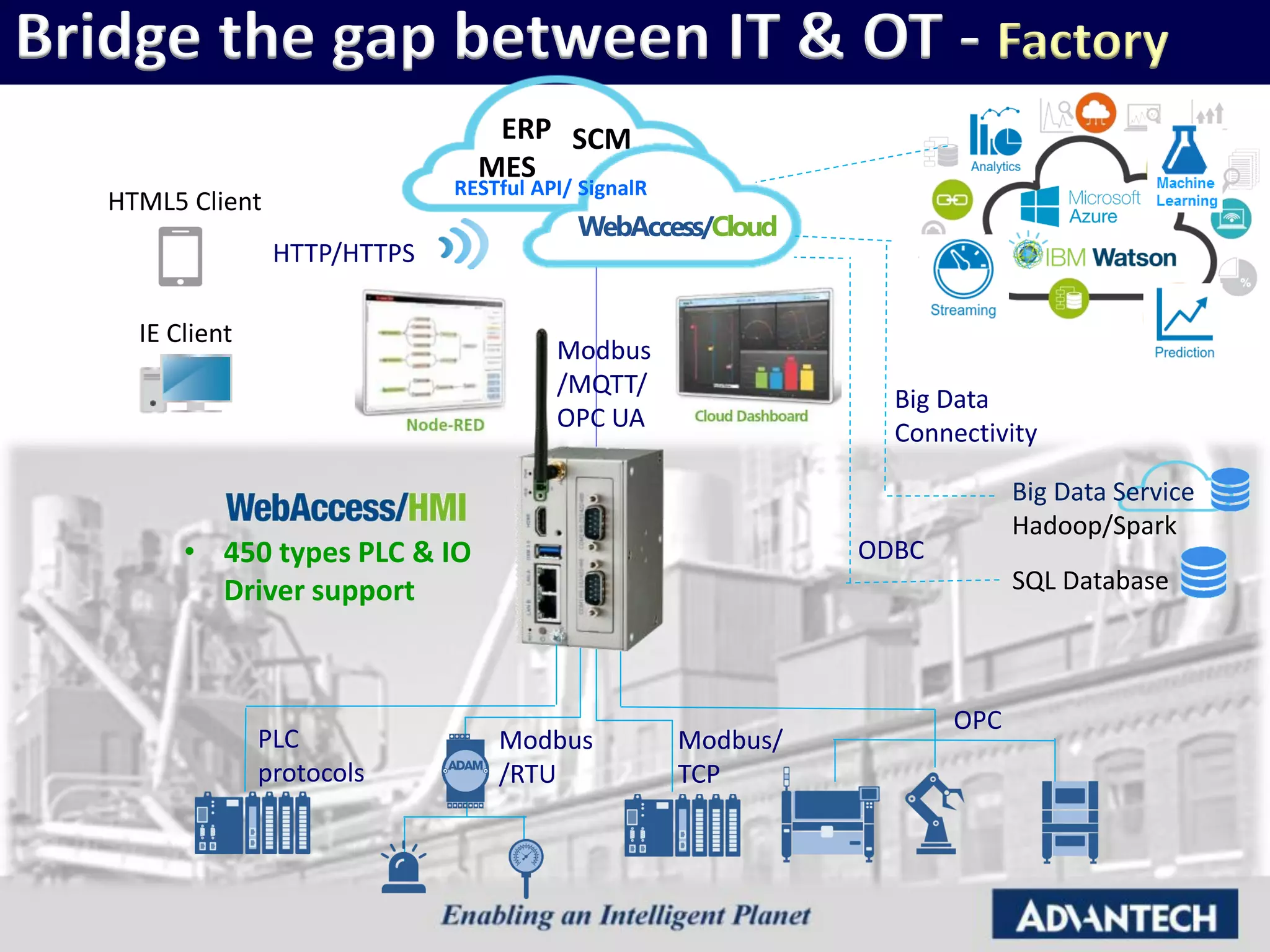

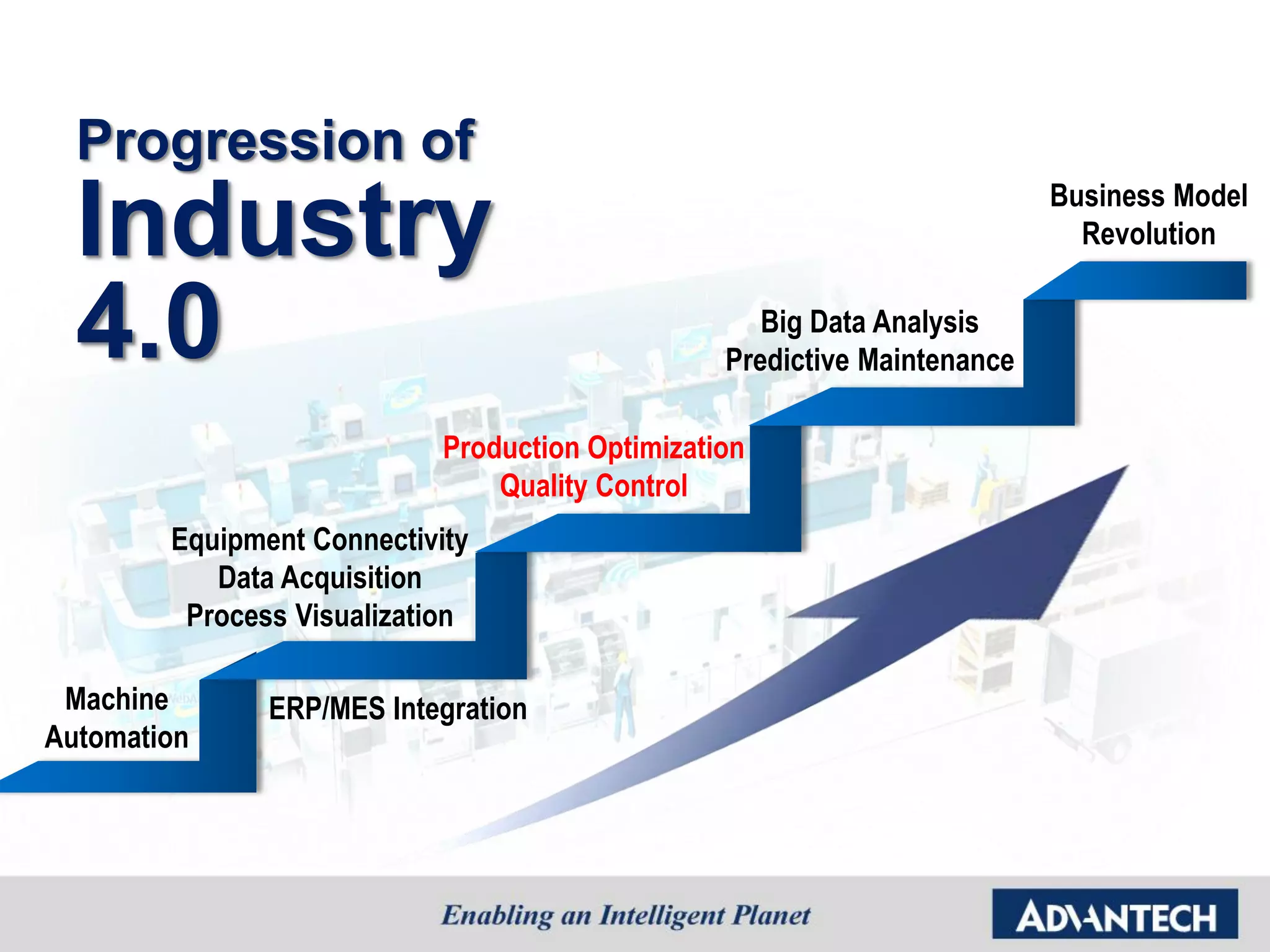

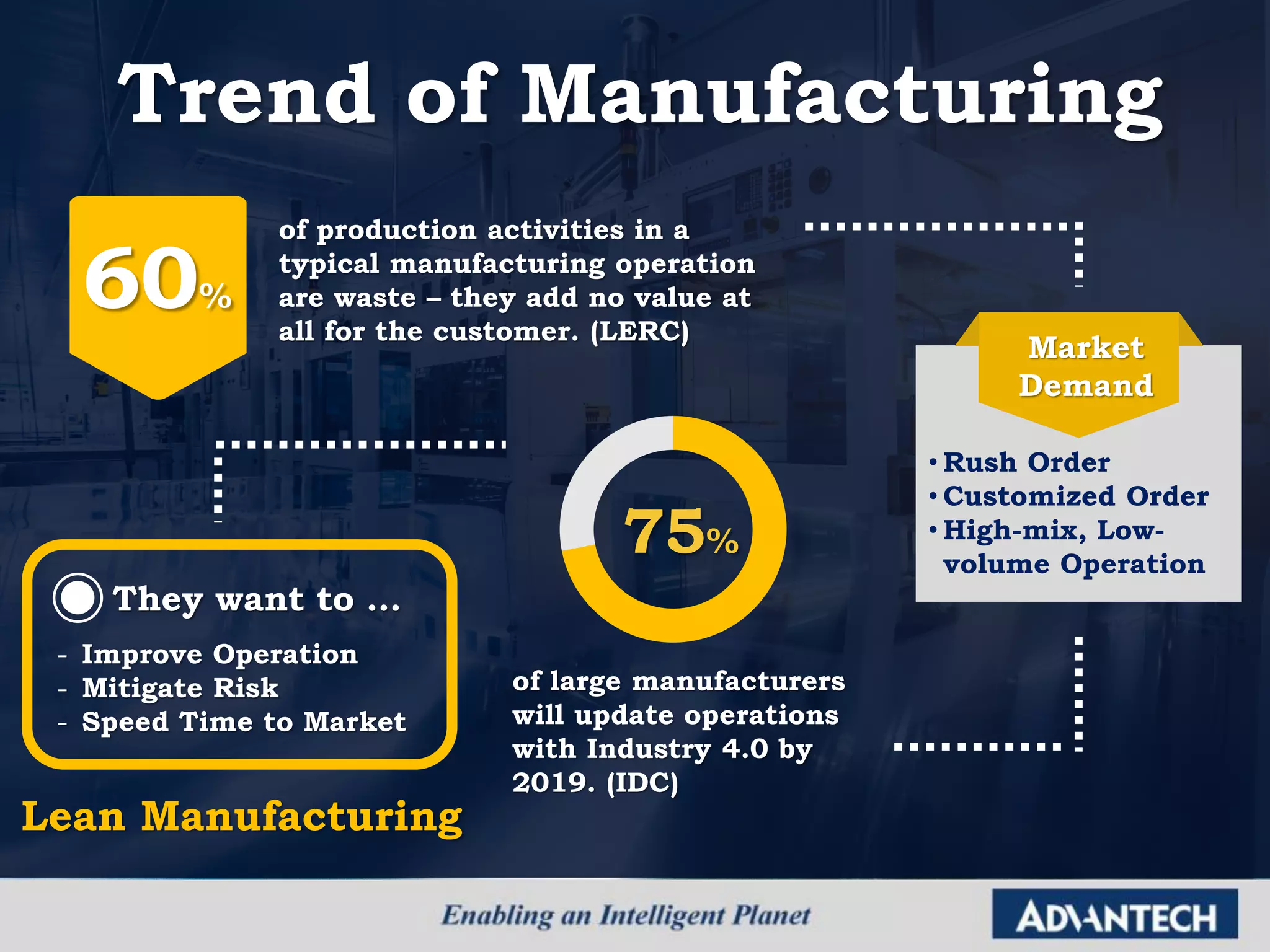

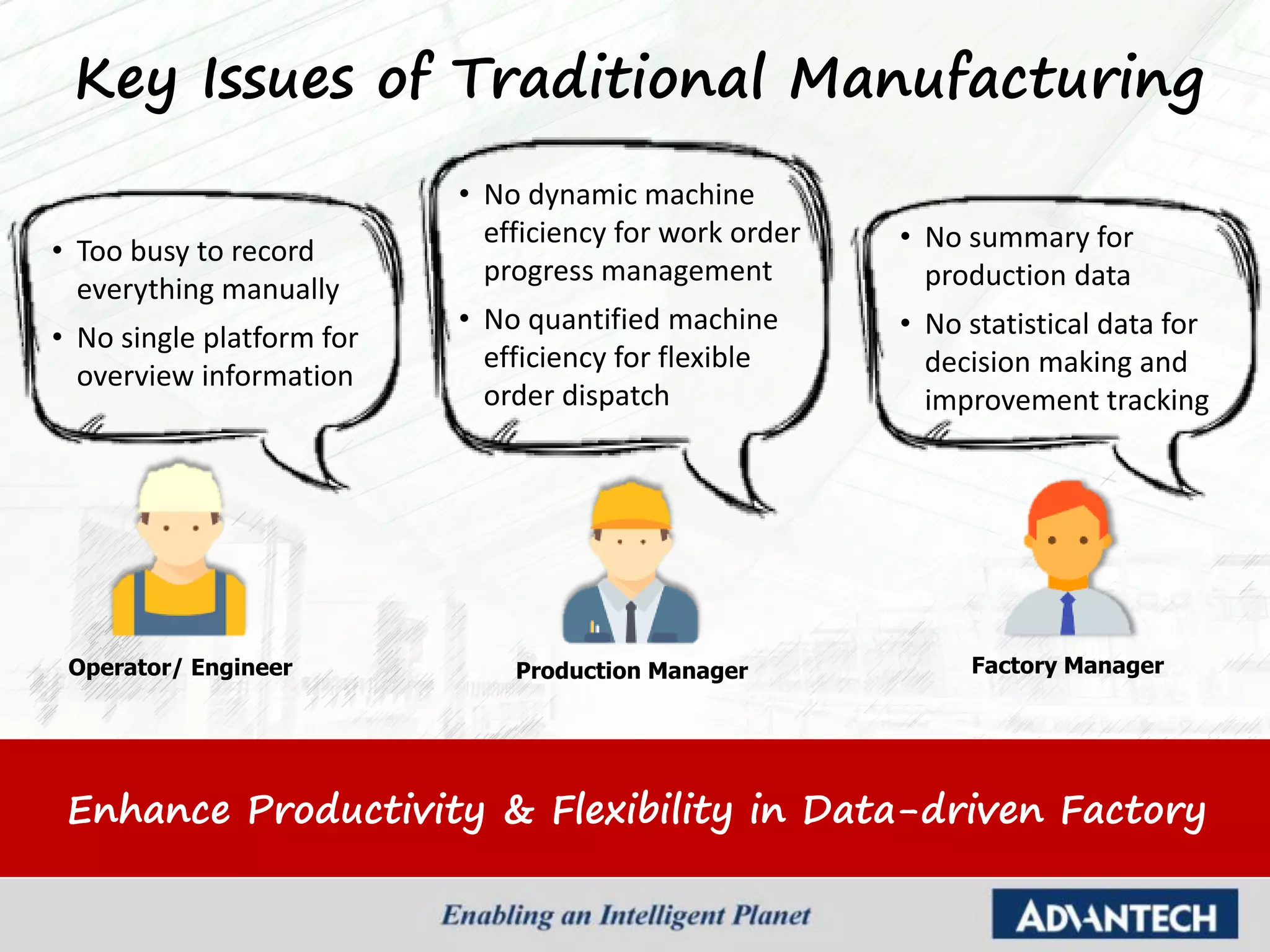

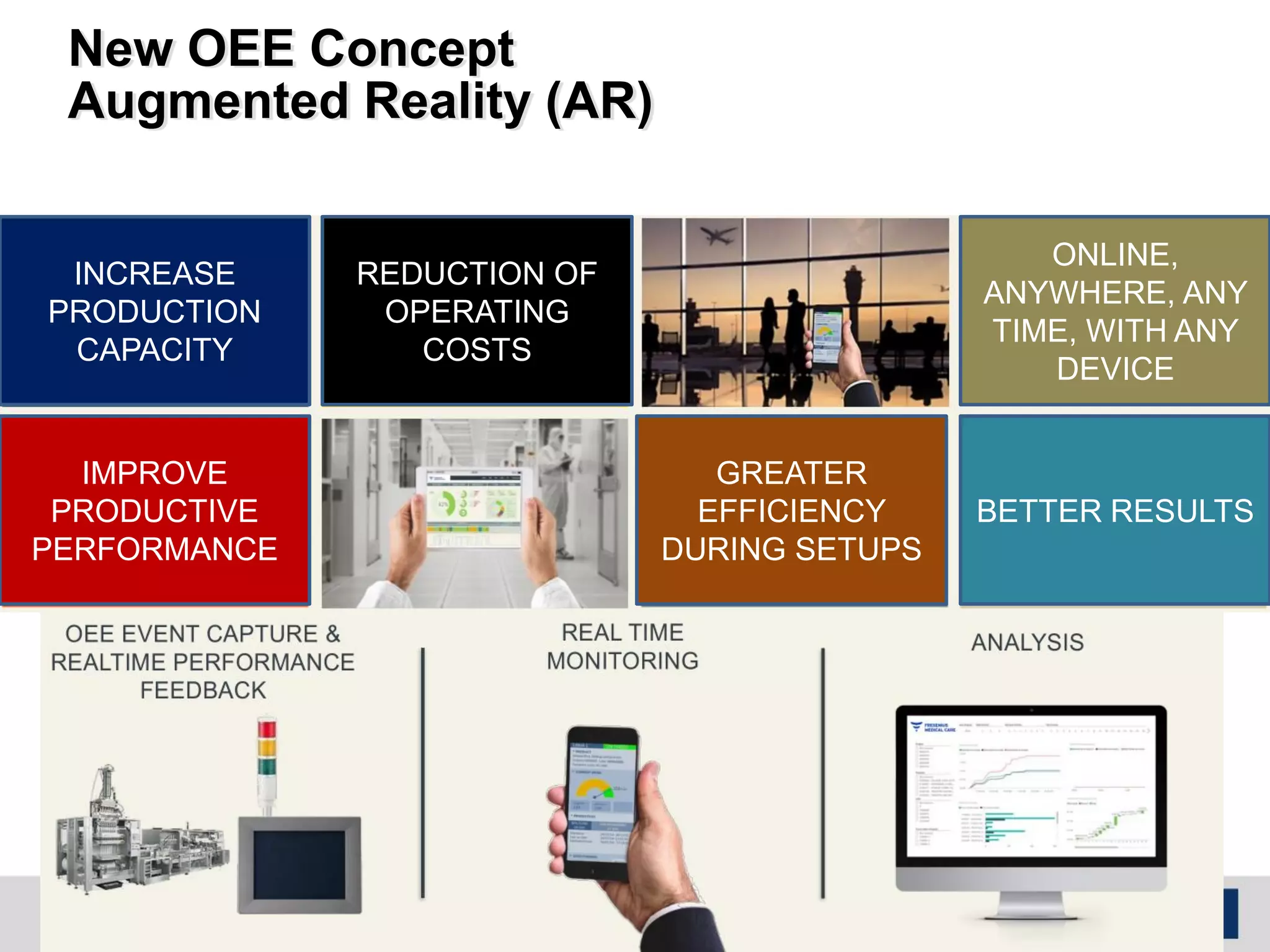

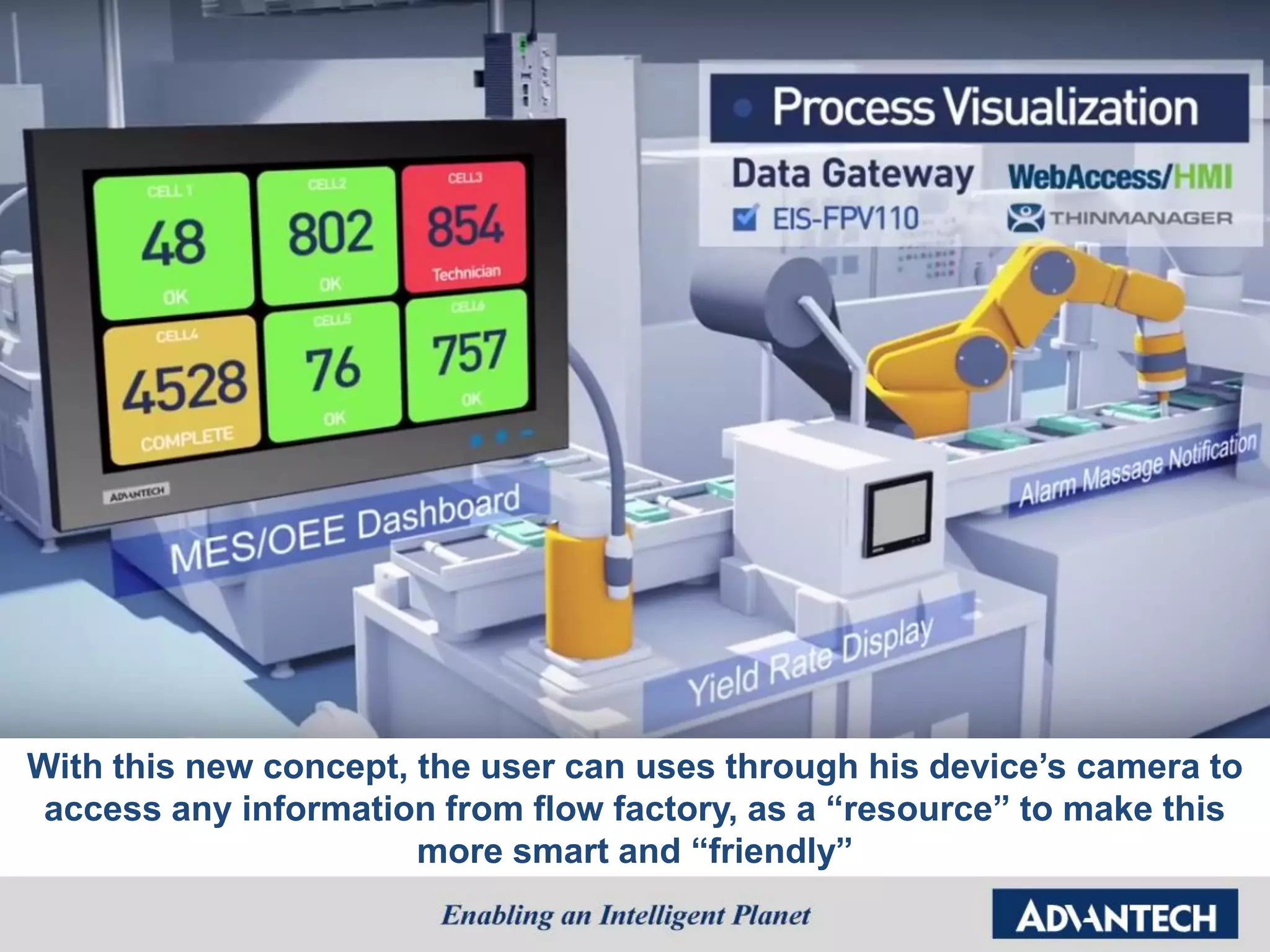

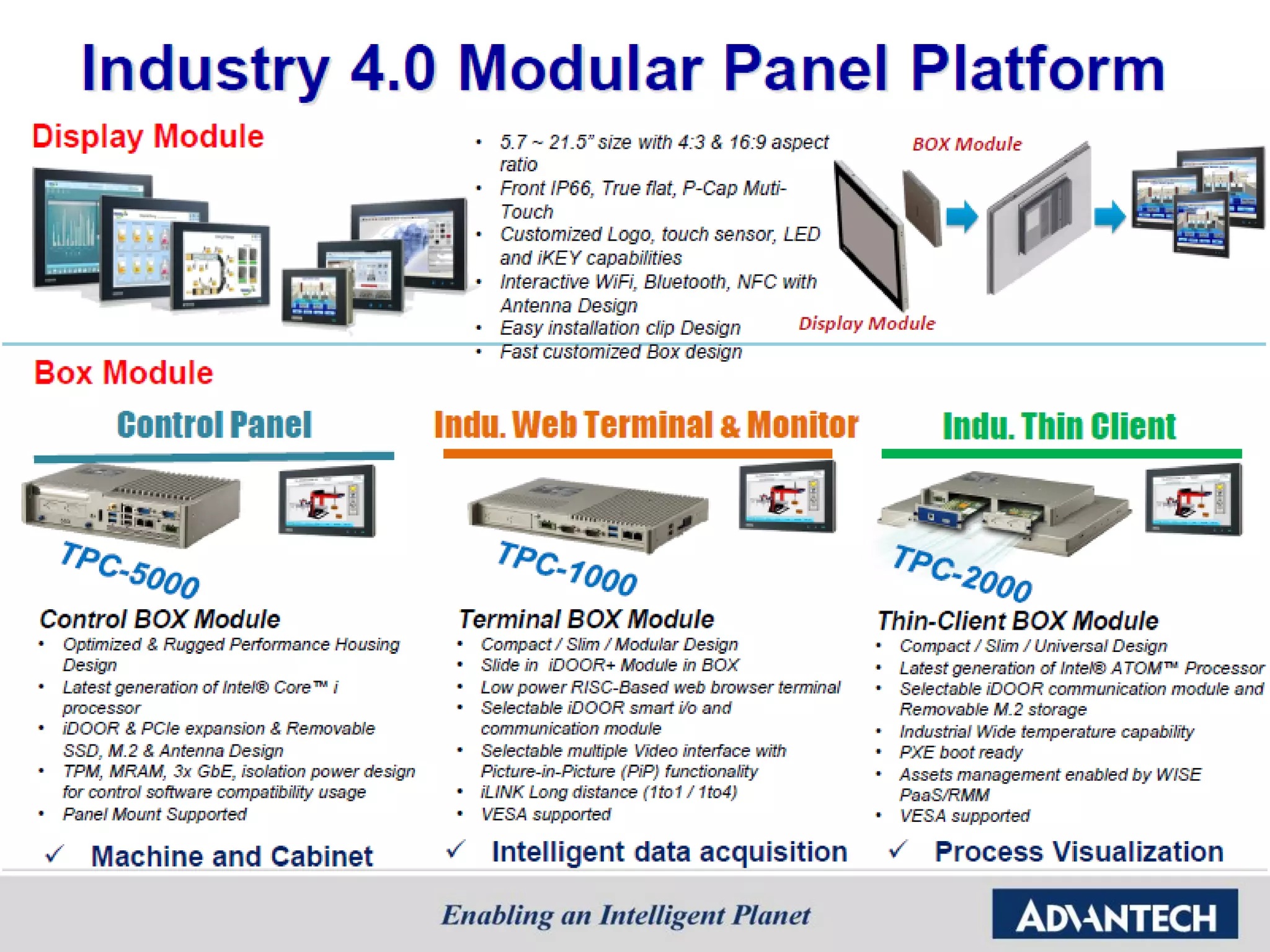

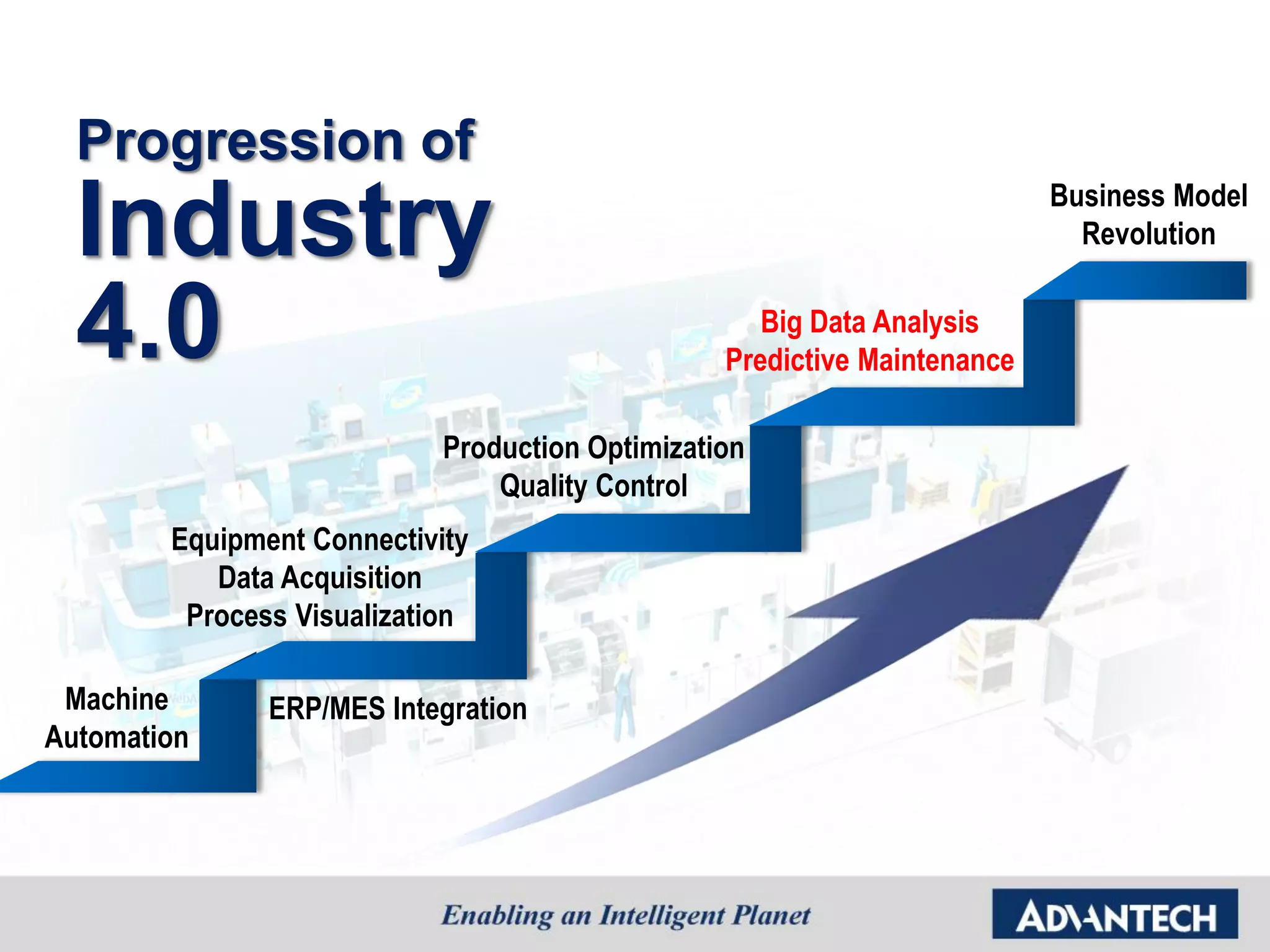

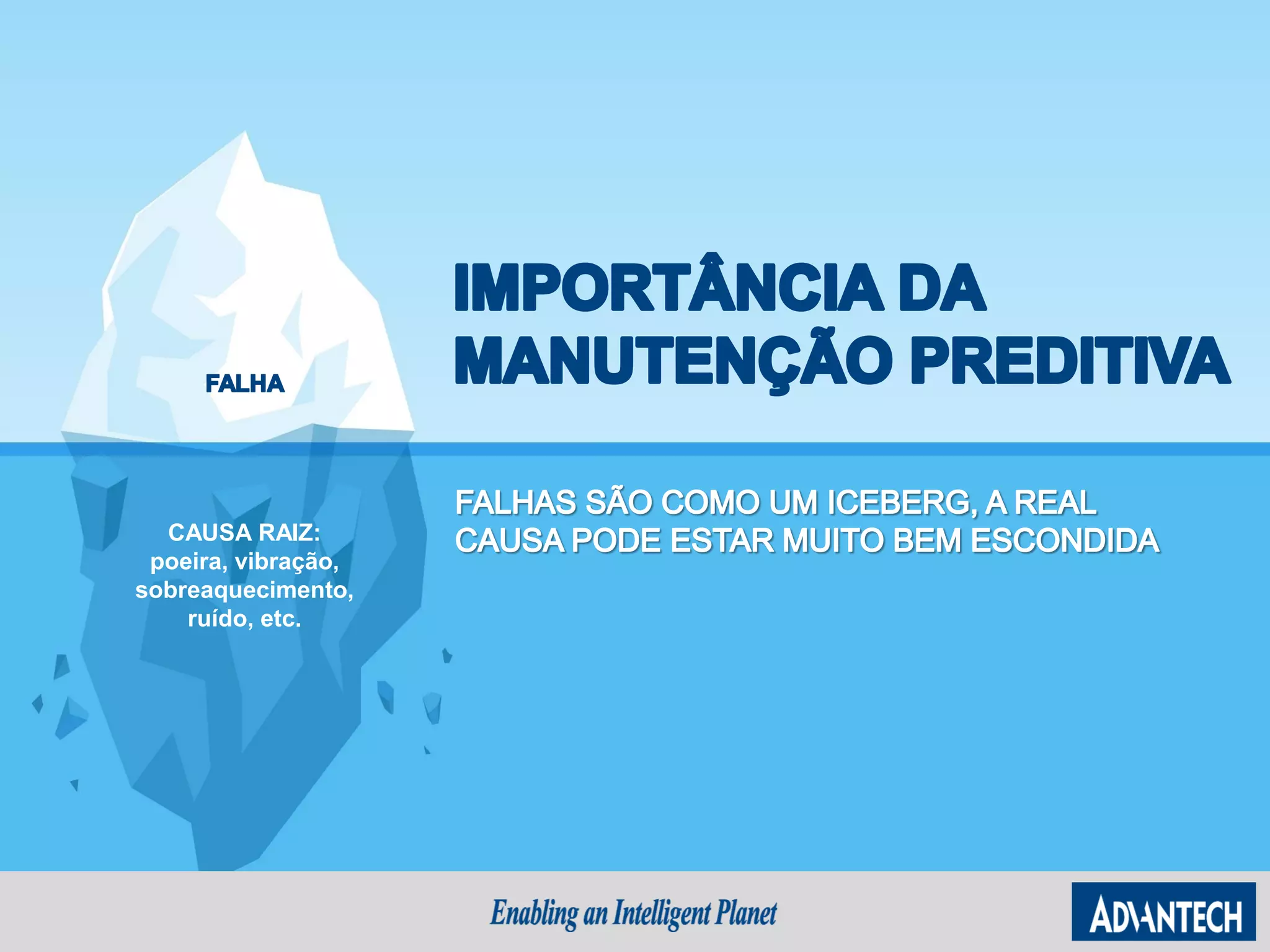

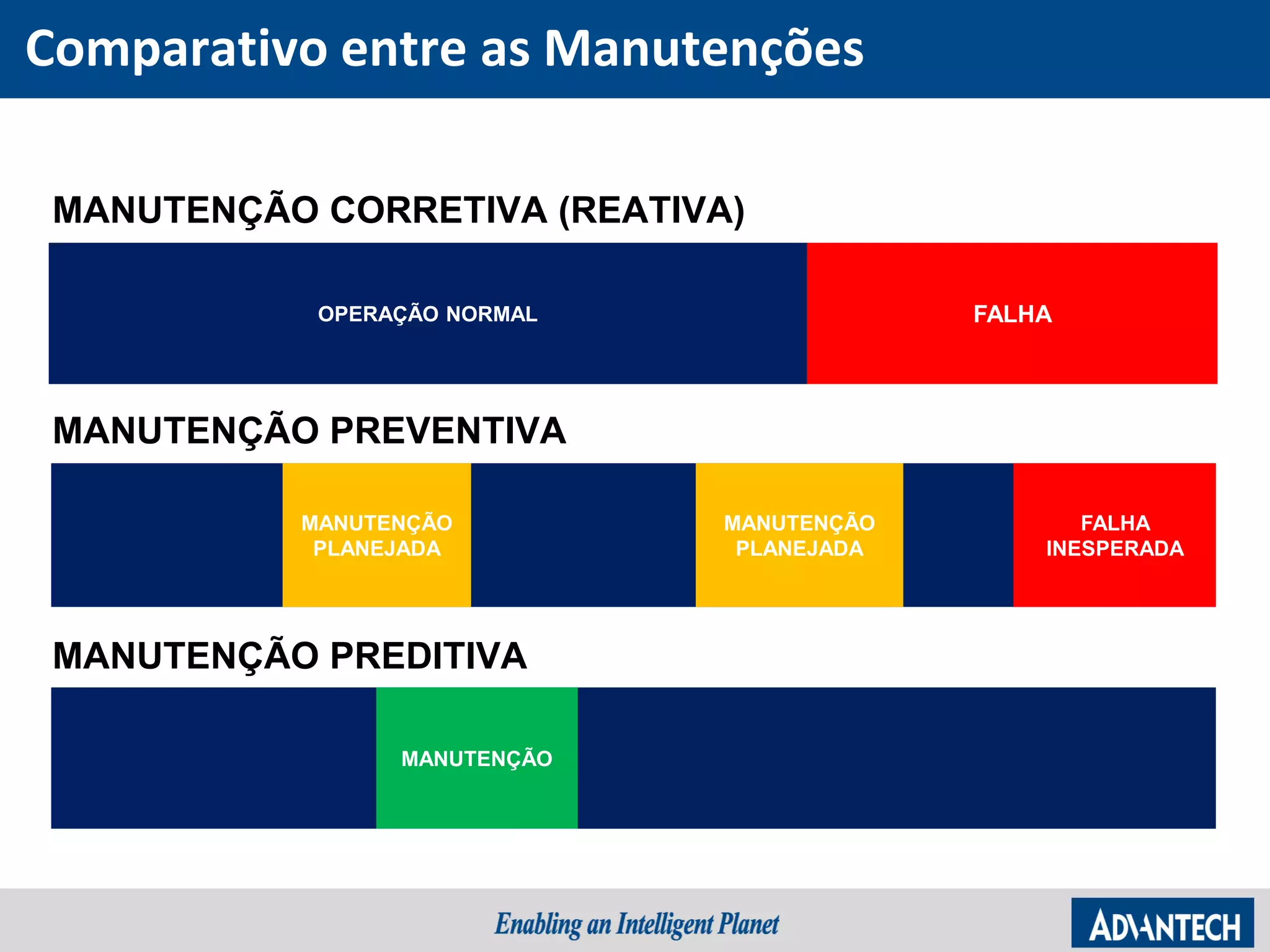

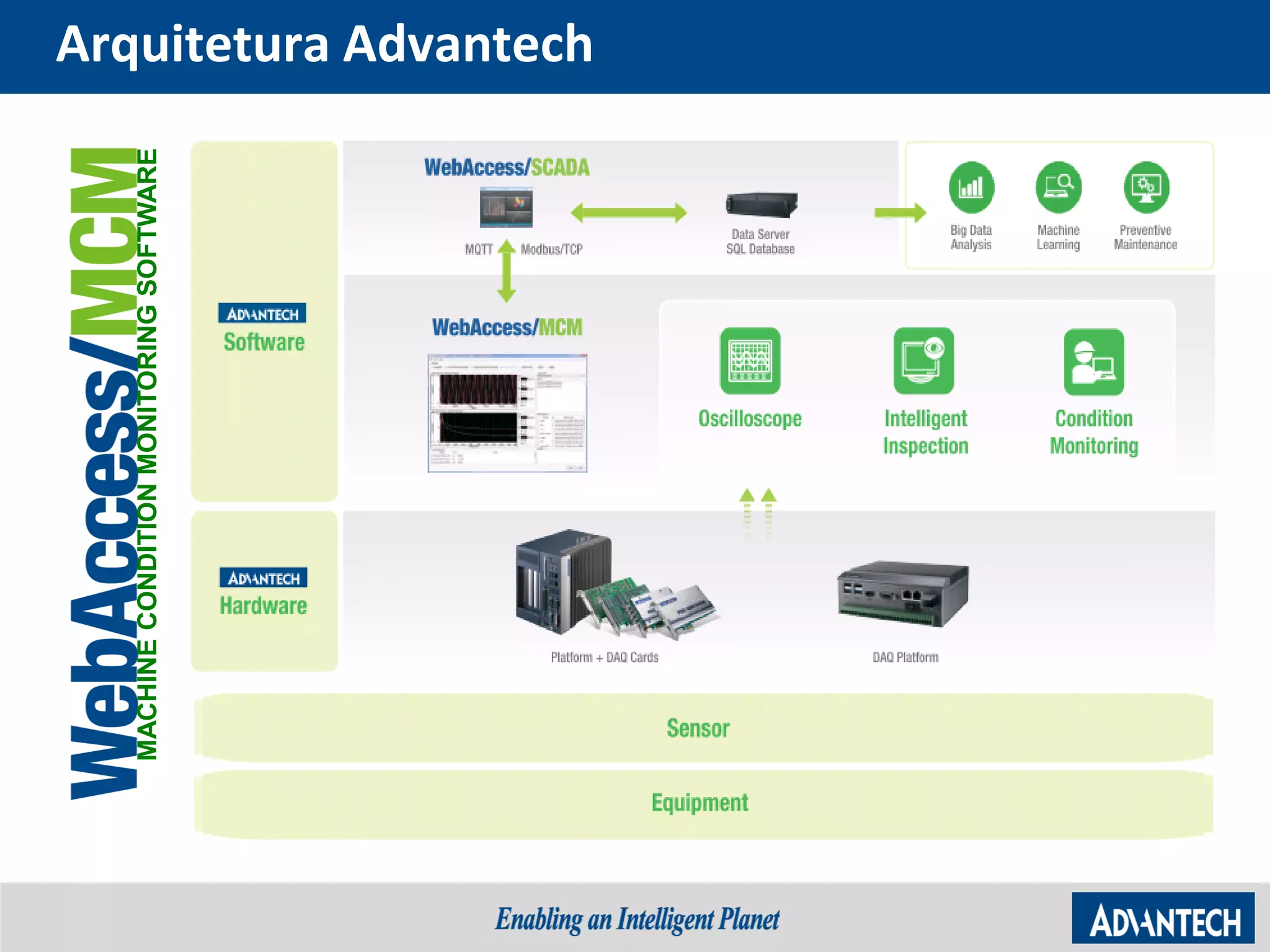

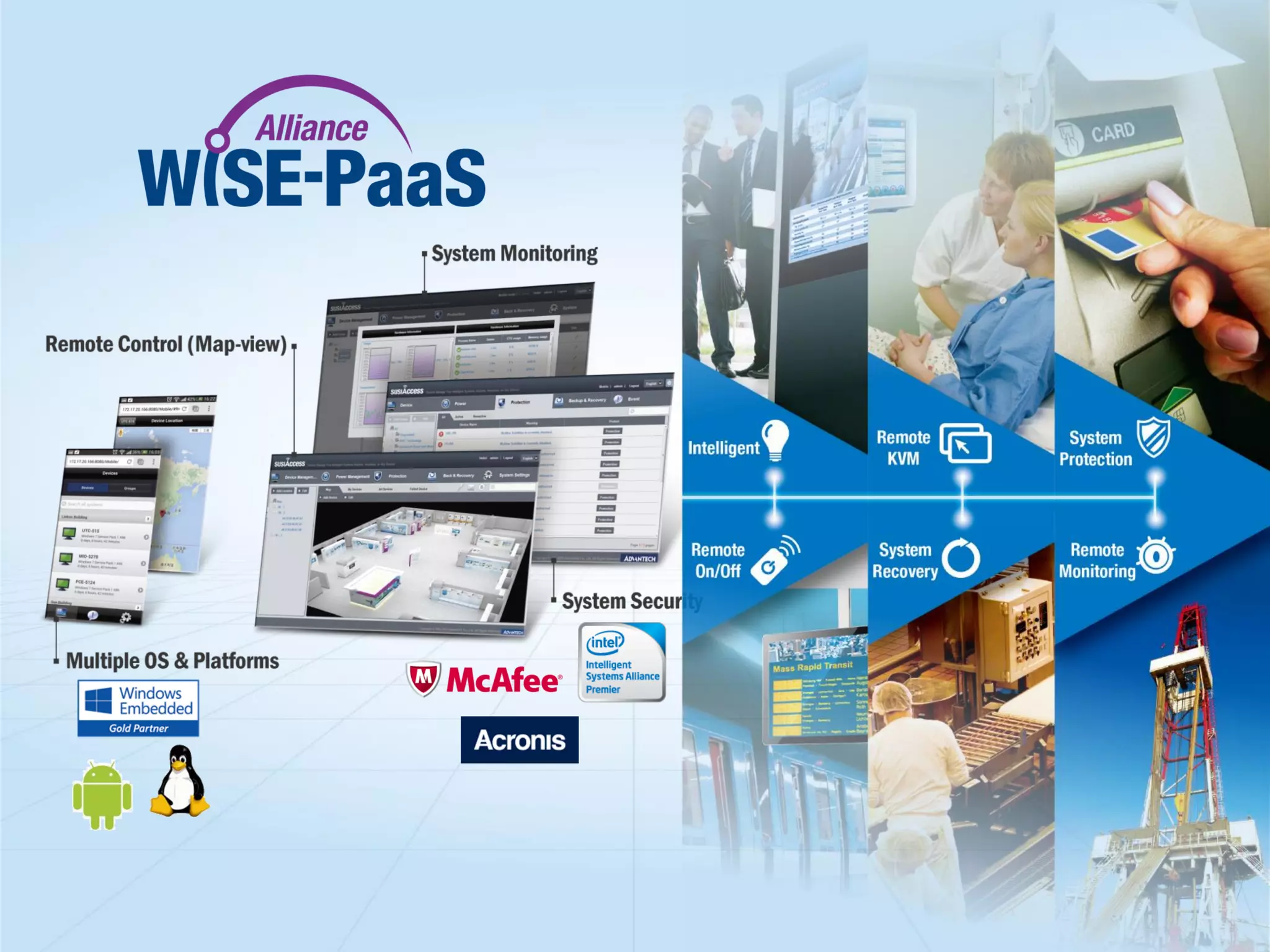

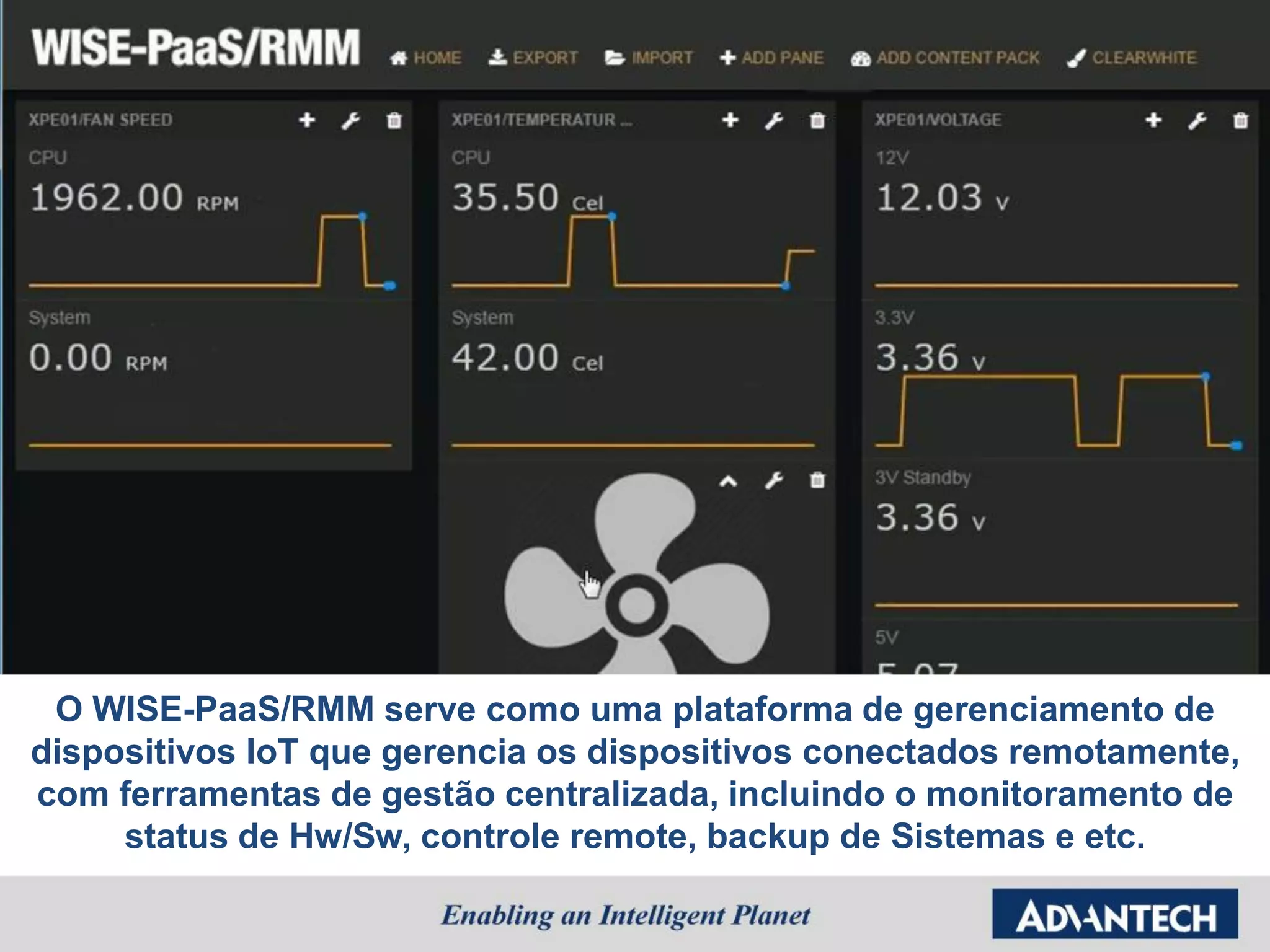

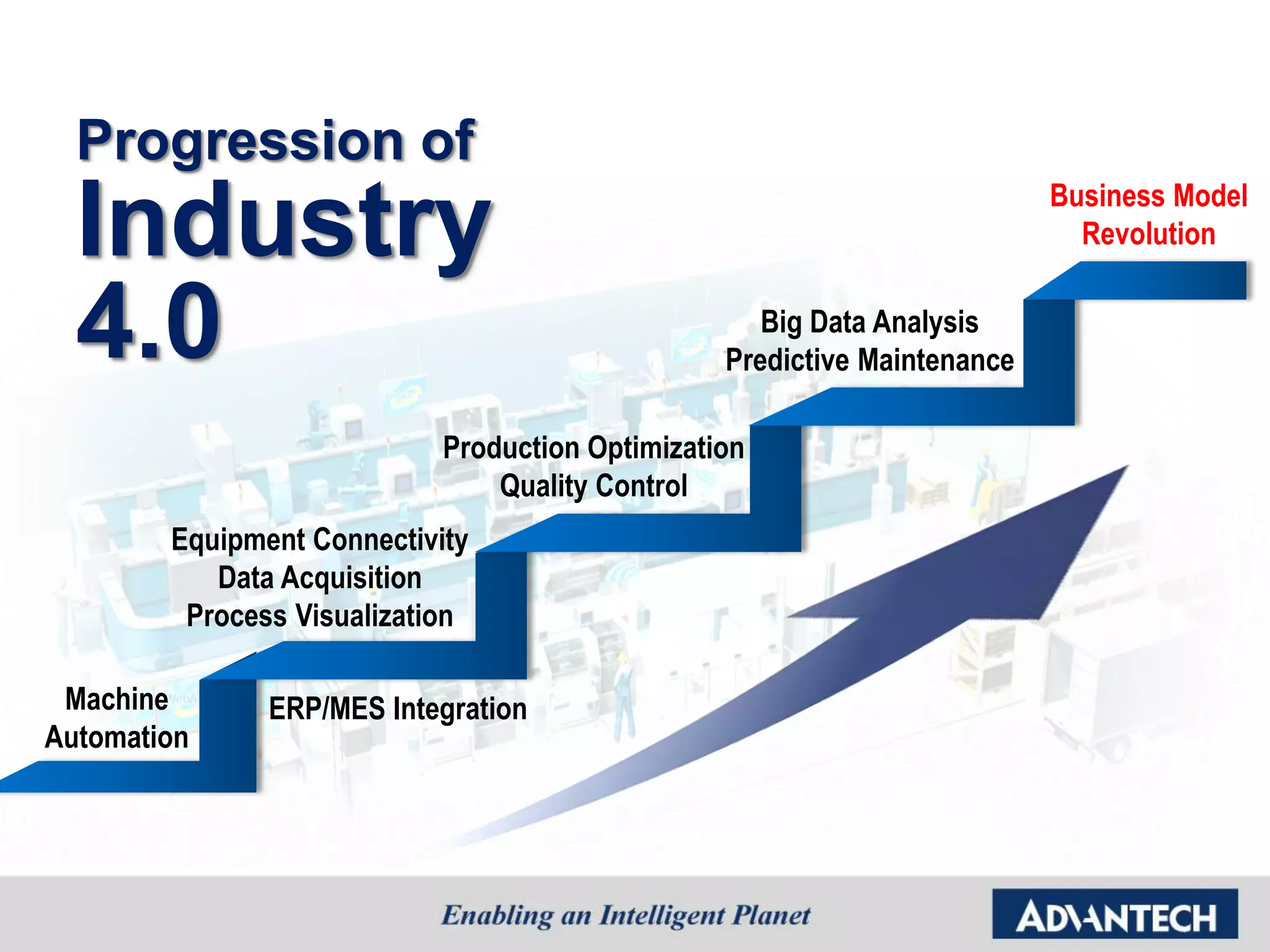

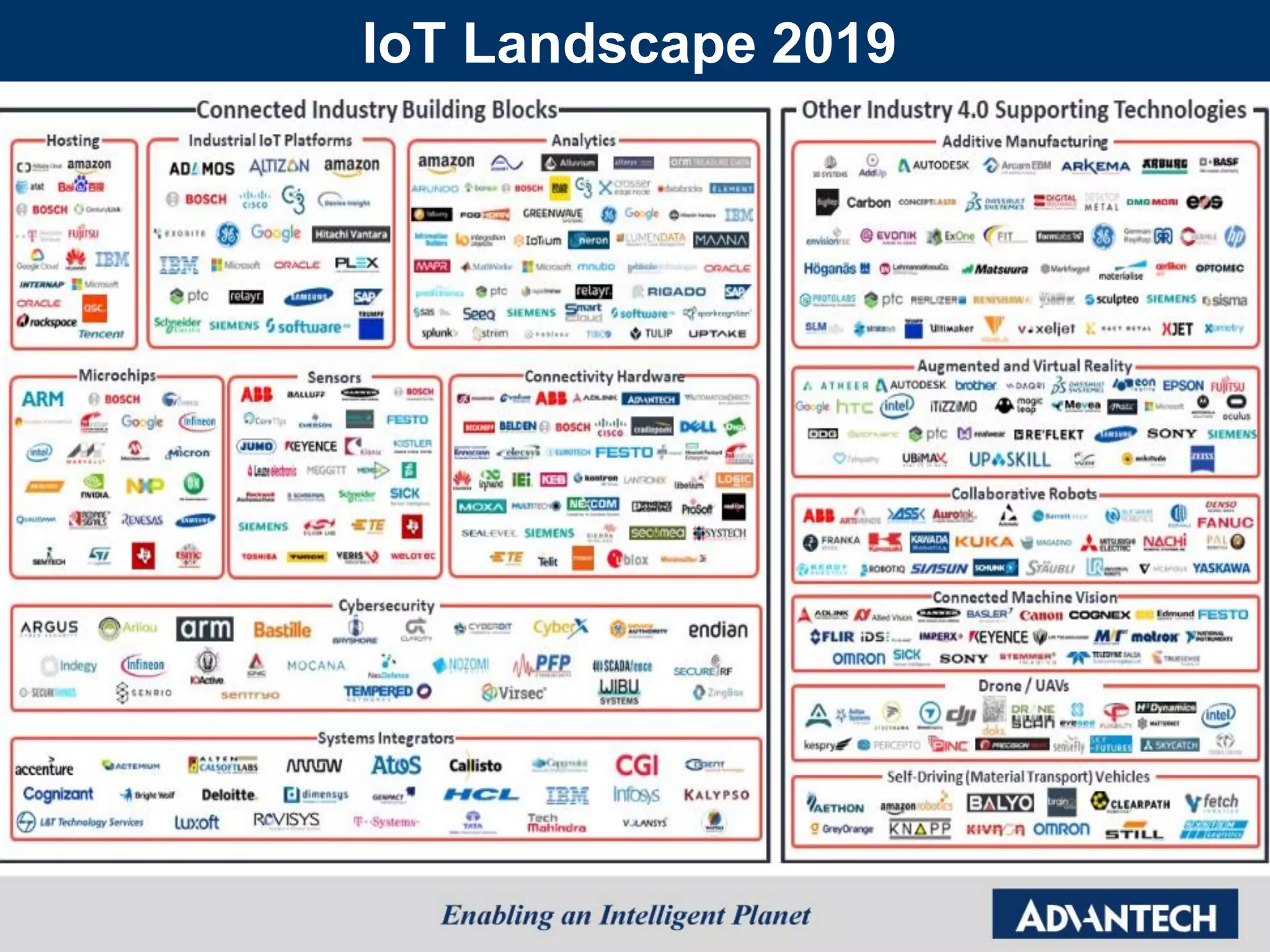

The document outlines Advantech's role in the Industrial Internet of Things (IIoT) sector, focusing on data connectivity and the transition to Industry 4.0. It discusses Advantech's solutions for smart cities and integrated cloud platforms while highlighting market challenges such as the lack of connectivity for legacy devices. The text also details historical and future strategies for optimizing industrial operations through enhanced data analytics and management systems.