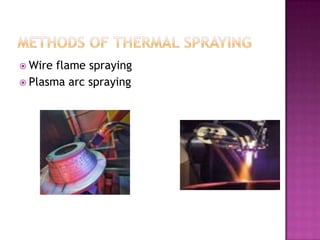

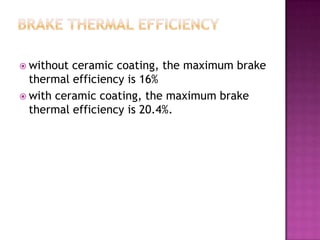

Thermal barrier coatings were originally developed for aircraft engines in 1940 but are now being tested for use in diesel engines. These coatings can reduce the metal temperature of engine components by up to 170 degrees Celsius. There are two main coating techniques - surface preparation and thermal spraying. Thermal spraying techniques like wire flame spraying and plasma arc spraying are used to melt and spray coating materials like metallic wires or powder onto engine components. The use of ceramic thermal barrier coatings on a single cylinder diesel engine resulted in increased brake thermal efficiency from 16% to 20.4%.