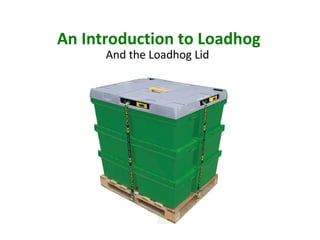

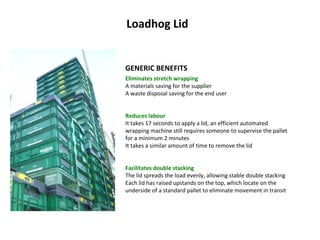

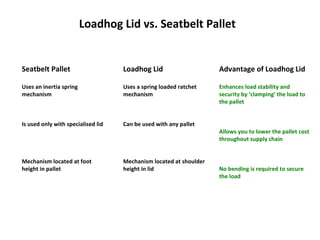

Loadhog Lid is a plastic pallet lid with retractable straps that secures pallet loads quickly without the need for disposable wrapping or banding. It takes 17 seconds to apply the lid versus 2 minutes to supervise wrapping. The lid spreads weight evenly to allow for stable double stacking. The Loadhog Lid enhances stability and security by clamping the load to the pallet, and allows lowering pallet costs. It uses a spring-loaded ratchet mechanism located at shoulder height and can be used with any pallet type.