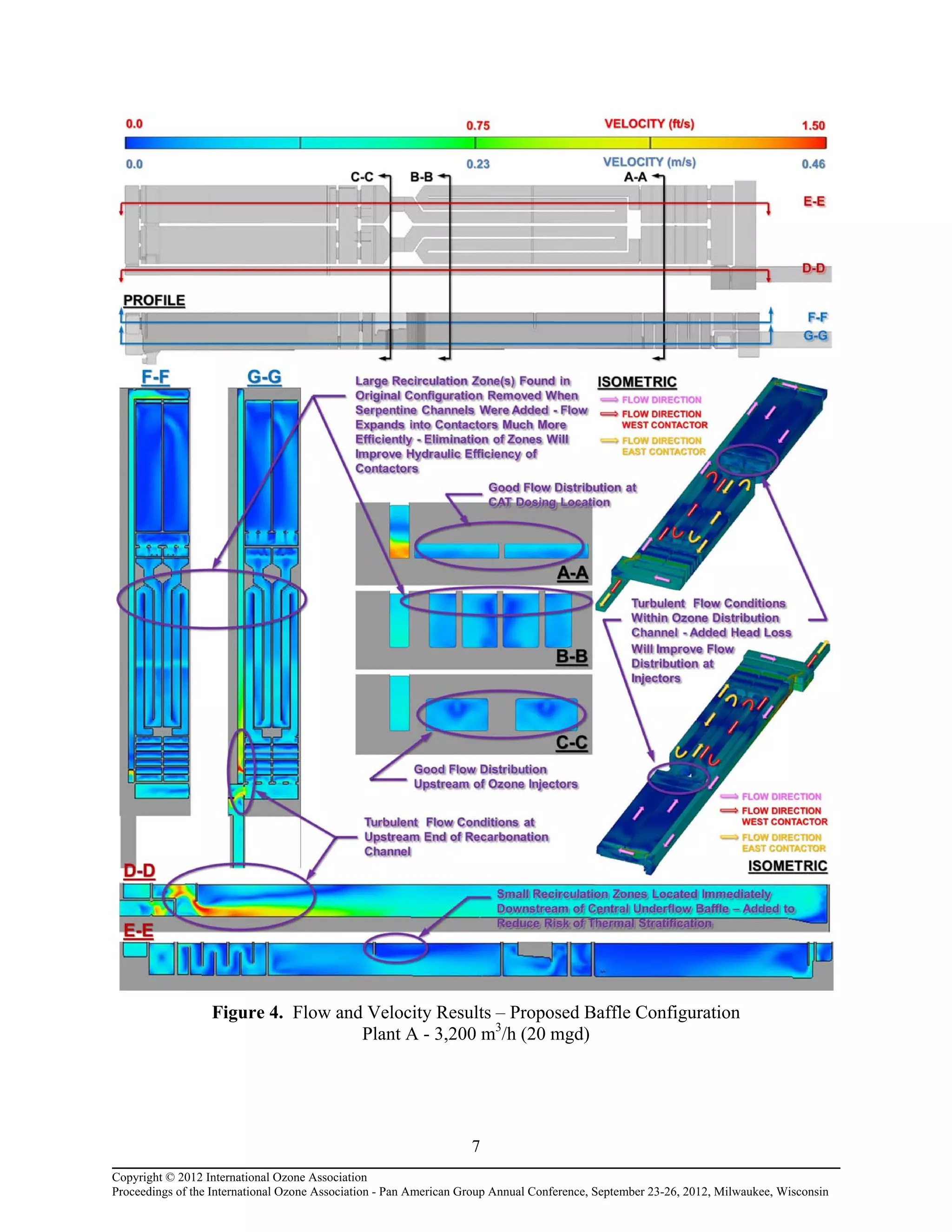

Computational fluid dynamic (CFD) modeling was used to optimize the design of four new ozone contactors being added to an existing water treatment plant. The CFD analysis identified design improvements that increased contactor performance while meeting constraints. Specifically, it minimized dead zones and improved flow transitions, resulting in more uniform flow distribution and reduced head loss. The modified design achieved excellent flow characteristics and contact times within design criteria. The optimized contactor design is expected to provide more effective ozone use and minimize residual levels.

![2

Copyright © 2012 International Ozone Association

Proceedings of the International Ozone Association - Pan American Group Annual Conference, September 23-26, 2012, Milwaukee, Wisconsin

Introduction

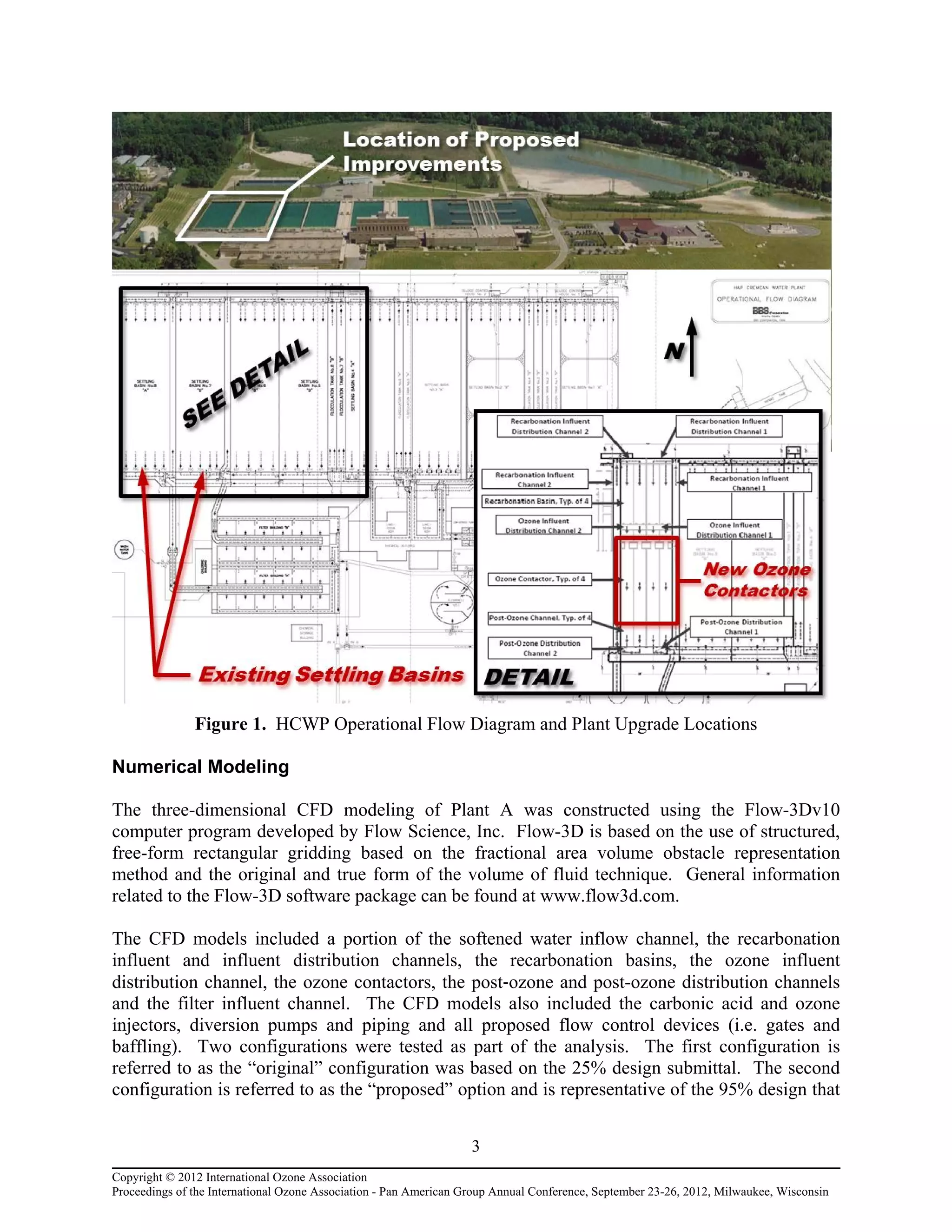

The existing Hap Cremean Water Plant (HCWP) is located east of I-270 off Morse Road in

Columbus, Ohio. It is currently the largest water treatment facility in the City of Columbus

(City), serving a population of more than 500,000 people. The treatment facility consists of two

parallel treatment trains, Plant A and Plant B, beginning at a raw water influent screening station

and continuing through all treatment processes including mechanical screening, low‐service

pumping, alum coagulation/ flocculation/sedimentation, lime softening, recarbonation, dual-

media rapid sand filtration, and chlorine disinfection. Flows for Plants A and B each have an

approved rated capacity of 236.6 cubic meters per hour (m3

/h) (62.5 million gallons per day

[mgd]) and are typically segregated although flow streams can be periodically joined and then re‐

divided during routine maintenance activities.

In April 2010 the City authorized a capital improvement project that included an upgrade of the

existing recarbonation system, addition of intermediate ozonation following recarbonation, and

conversion/rehabilitation of the existing sand filters for operation as biologically active filters.

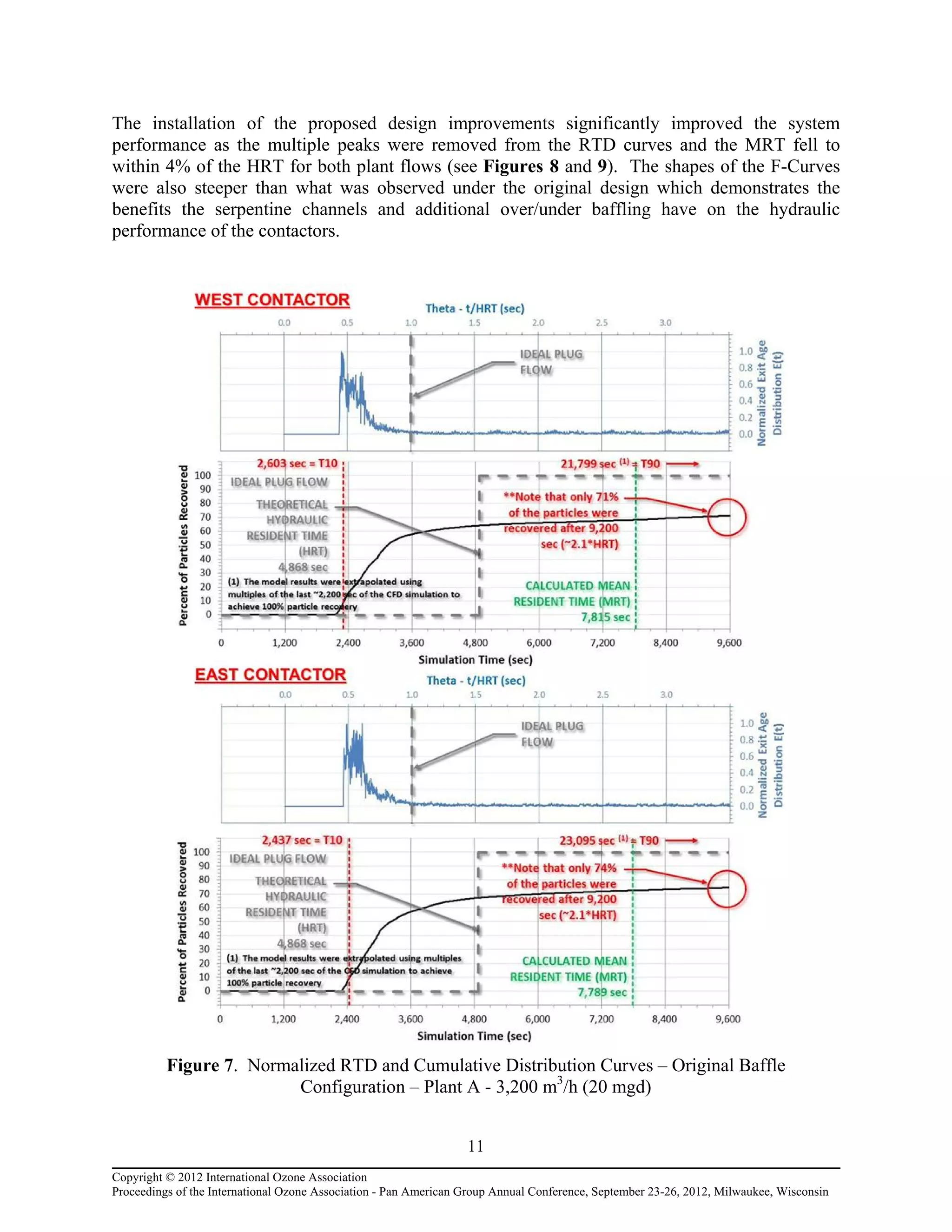

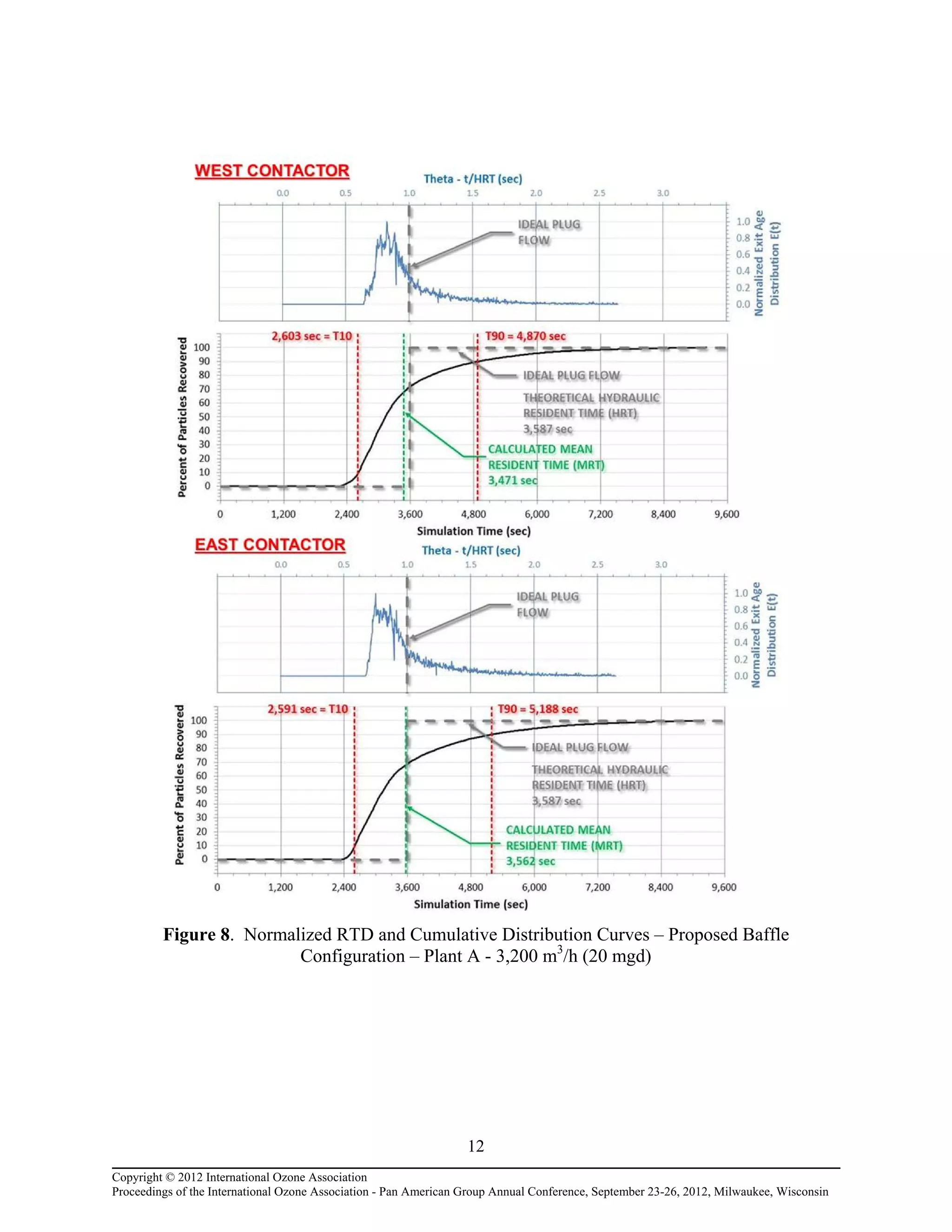

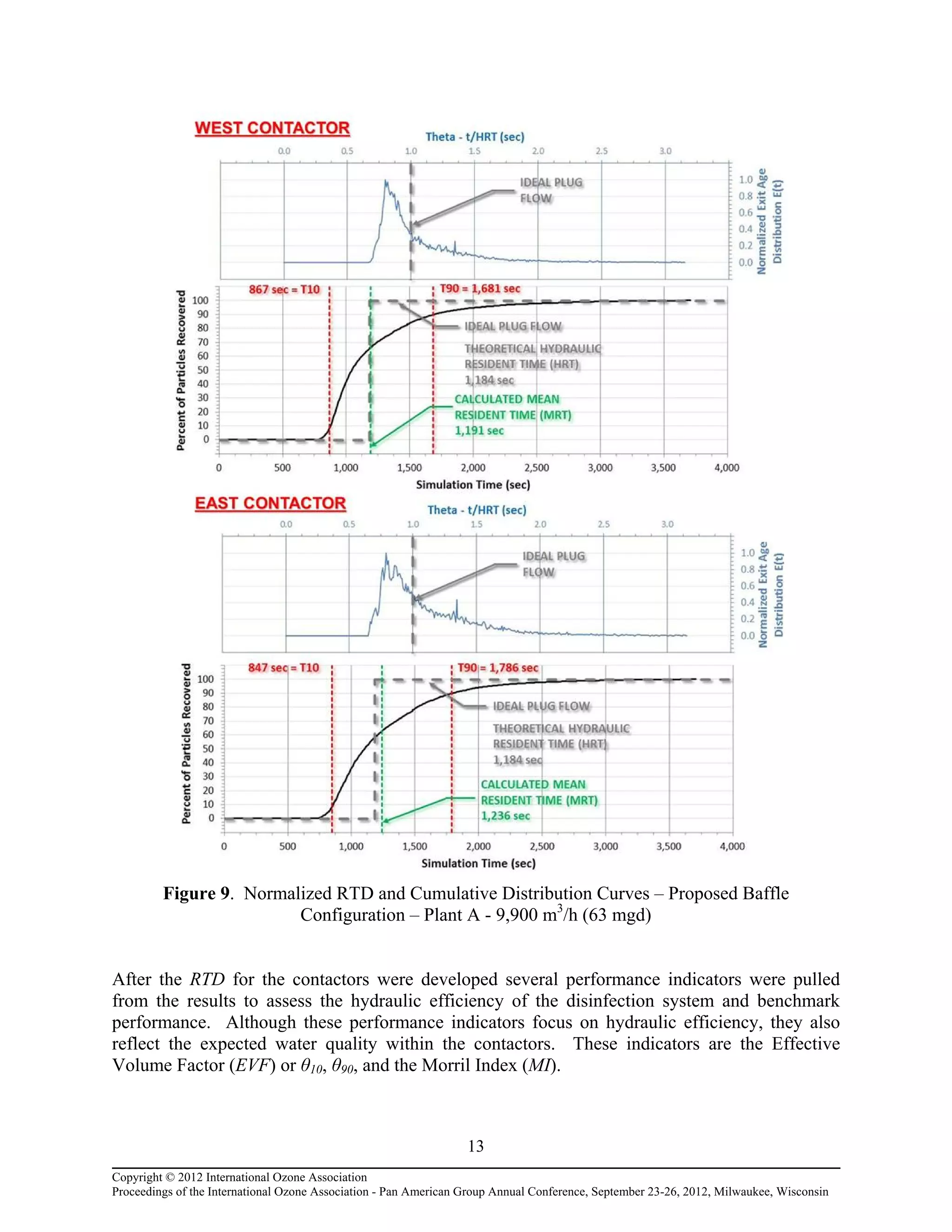

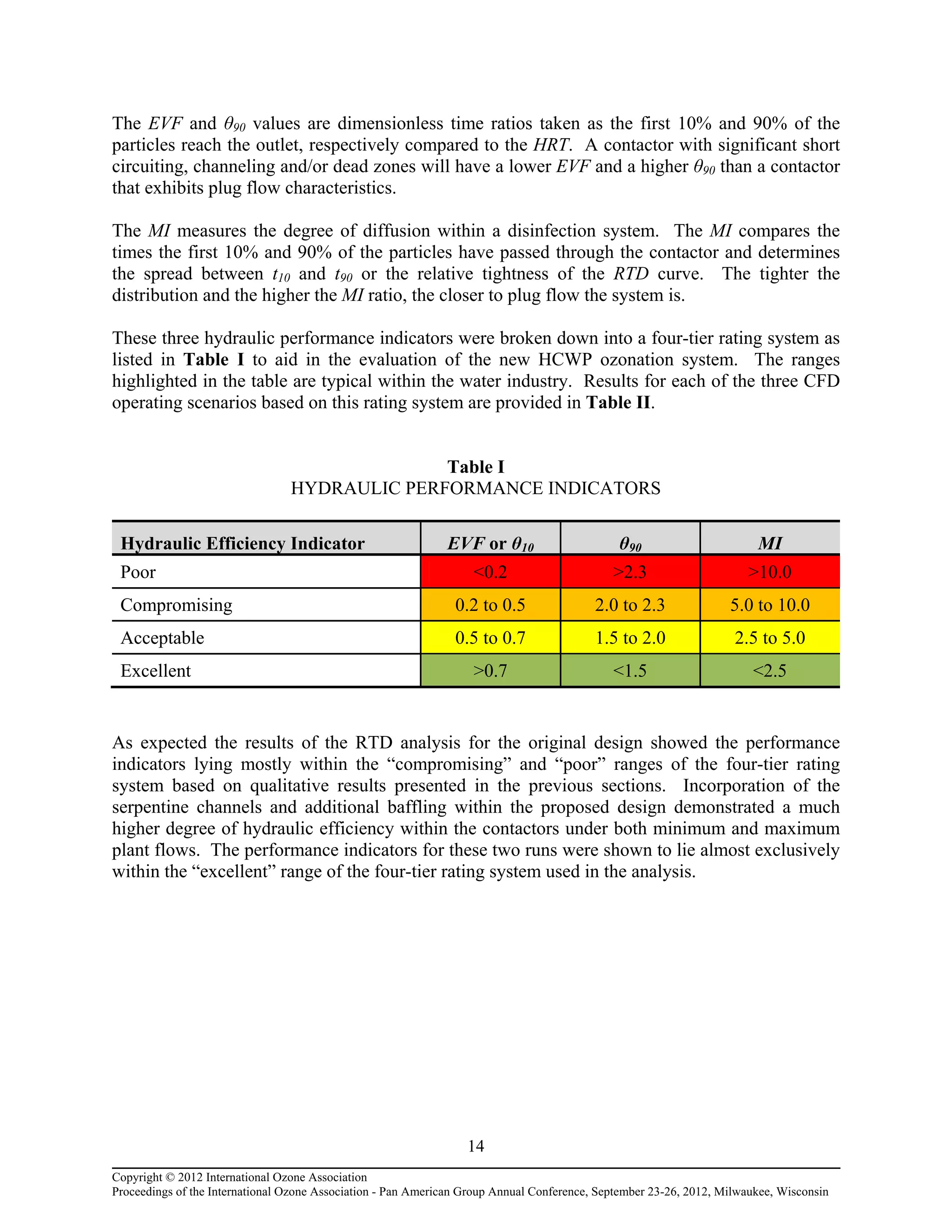

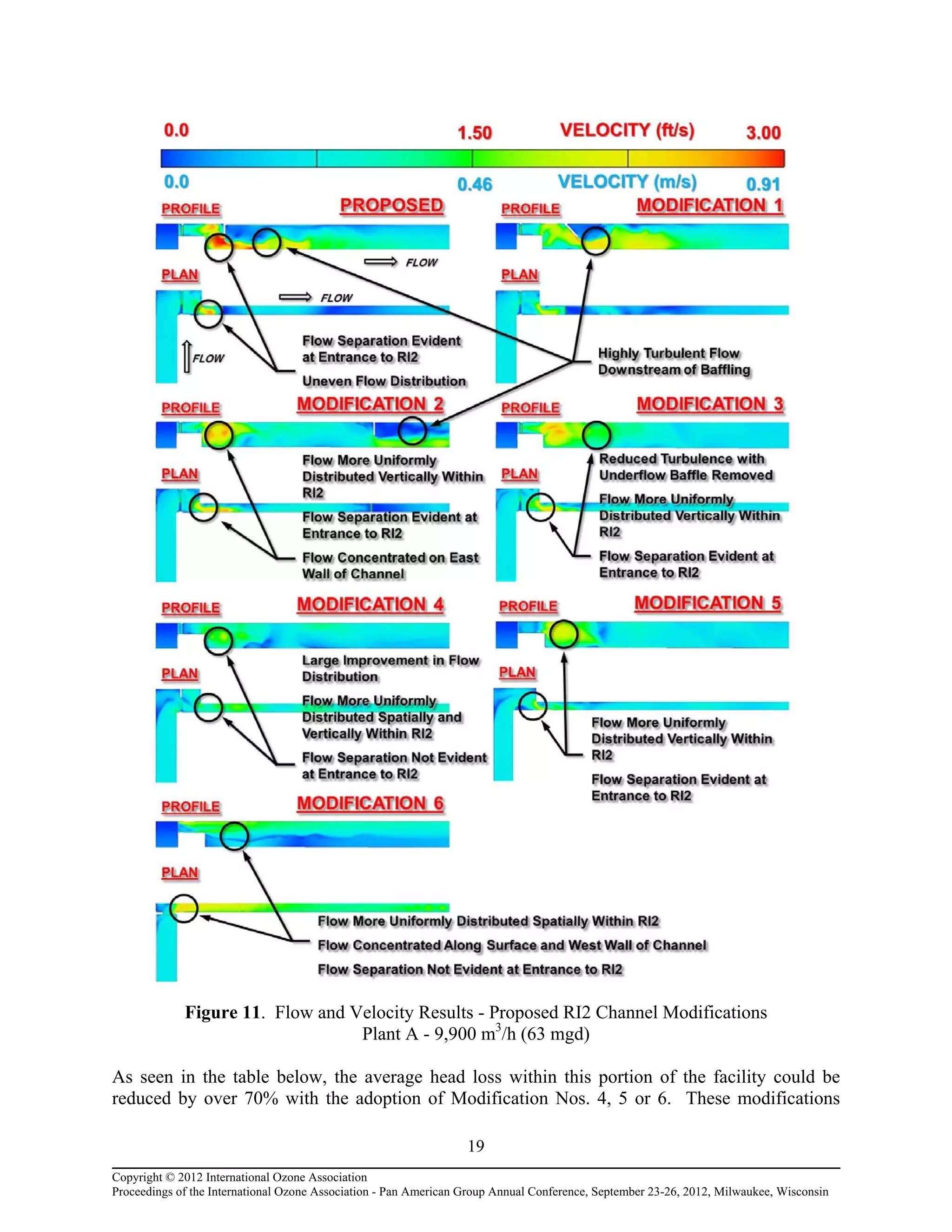

Figure 1 shows the operational flow diagram of the plant with the location of the proposed

upgrades. The new treatment plant improvements were designed to ensure compliance with

upcoming water quality regulations, specifically addressing the Stage 2 Disinfection By-Products

Rule. The new ozonation system is the focus of this paper.

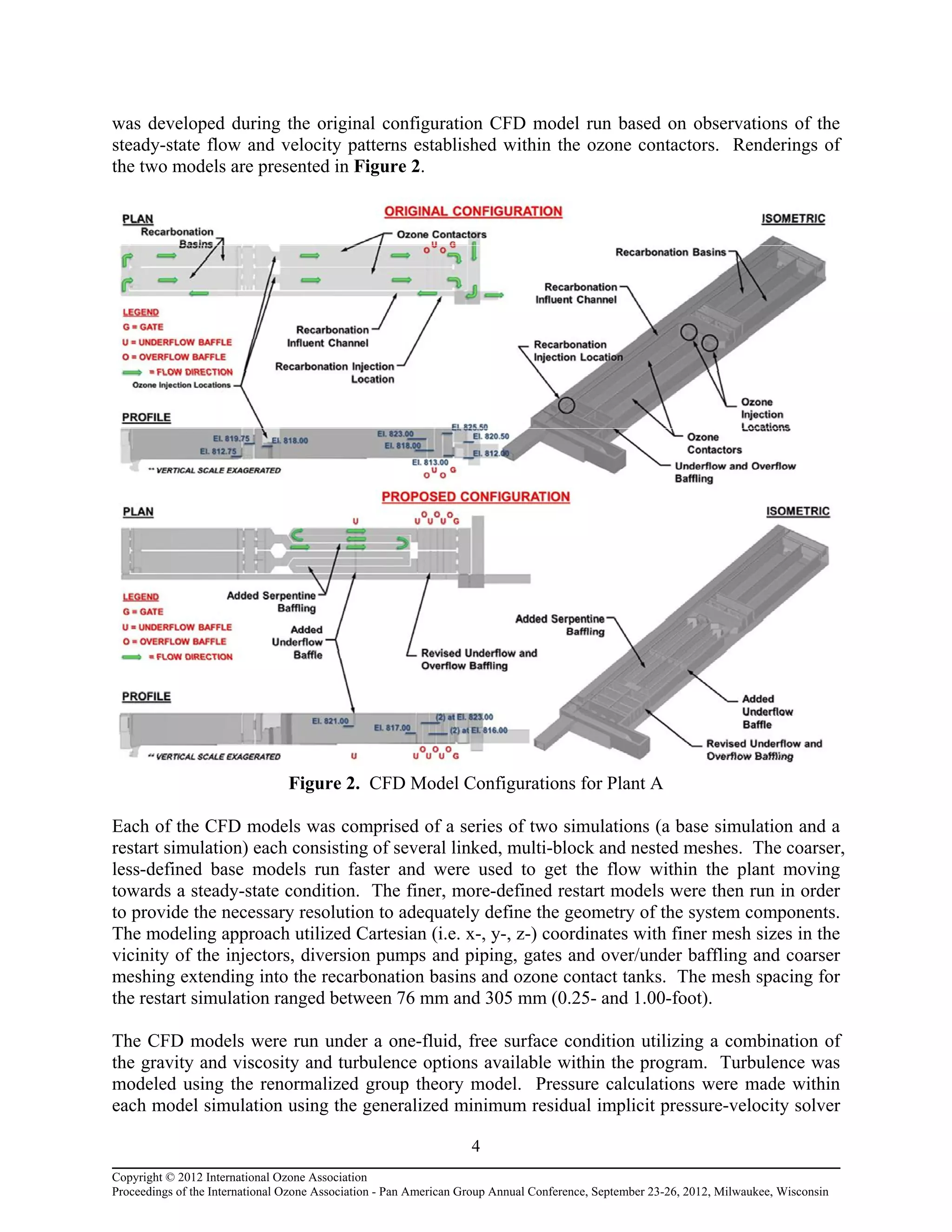

Due to the location and nature of the modifications within the existing system (i.e. converting

existing settling basins to ozone contactors), the main focus of the HCWP design became its

ability to maximize the efficiency of the ozonation process and limiting head loss trough the

plant.

To confirm that the new ozonation system would meet performance requirements, the design

team determined that Computational Fluid Dynamic (CFD) modeling was required in order to

develop the final locations and configurations of the new contactors, injectors, gates, and baffling

system(s). This conclusion was based on the site constraints at the plant and considered the

potential for the City to pursue post-construction treatment credits.

The CFD analysis was performed on the new ozonation system for Plant A. This plant was

chosen due to the symmetrical layout of the two plants and the lower degree of available

freeboard versus Plant B. The key issues to be resolved through the numerical modeling

approach included: 1) Developing necessary modifications to the contactor geometry and gate

and baffling system(s) to minimize short-circuiting and areas of recirculation/stagnation; 2)

Creating uniform flow distribution within the ozone influent and post-ozonation channels to

maximize dosing efficiency; 3) Determining the resident time distribution (RTD), mean resident

time (MRT) and the hydraulic efficiency of the new ozone contactors; and 4) Minimizing head

loss through the recarbonation and ozonation systems to limit structural modifications to the

upstream portion of the plants.](https://image.slidesharecdn.com/755241d1-464d-4a1b-a9ae-298016ab20b9-150413080802-conversion-gate01/75/Ozone-Contactor-Design-Improvements-using-CFD-Modeling-2-2048.jpg)