Oracle Enterprise Asset Management Command Center

This chapter covers the following topics:

• Overview

• Assets Dashboard

• Open Work Orders Dashboard

• Materials Dashboard

Enterprise Asset Management Command Center User Interface

Overview

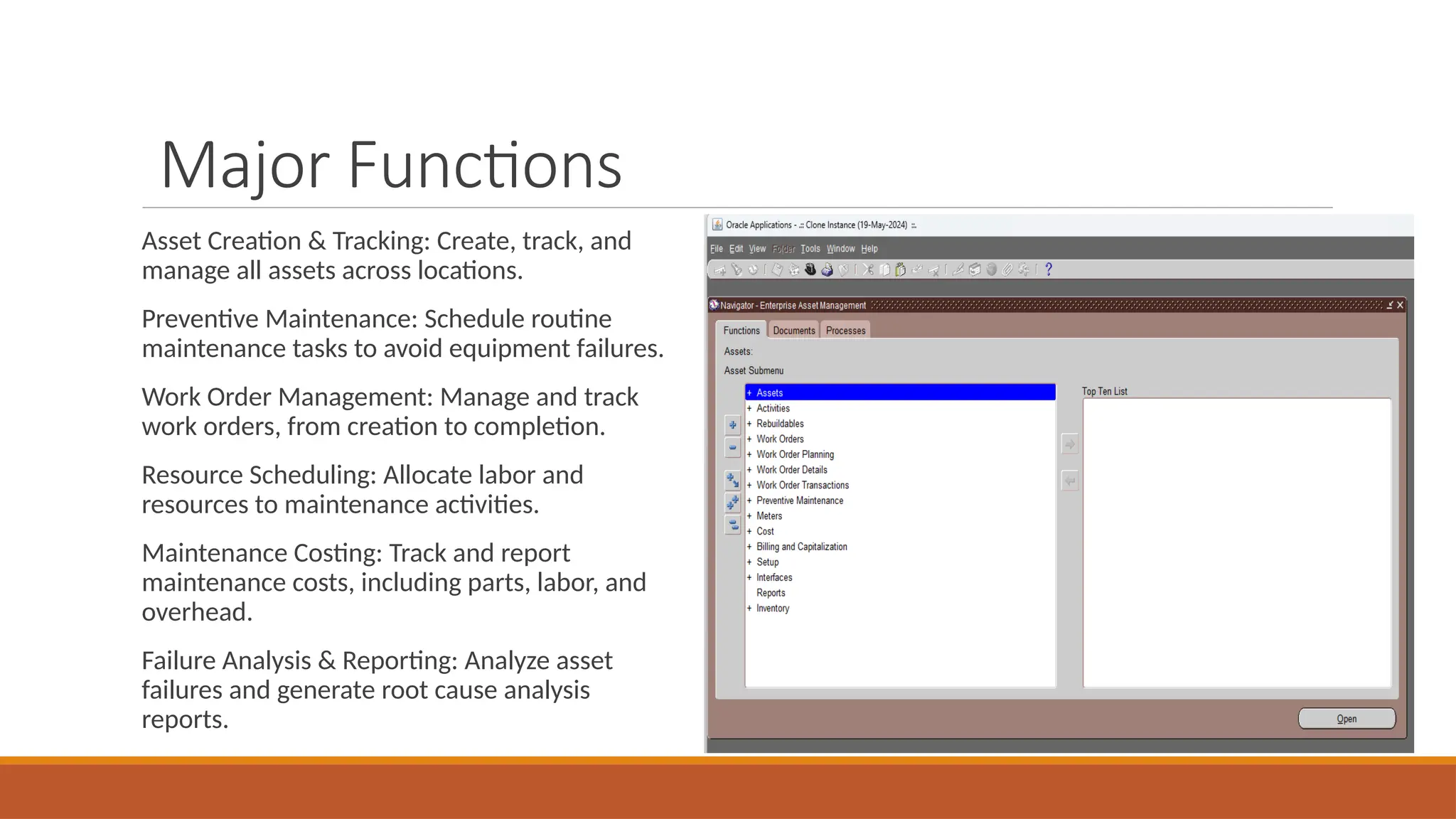

The Enterprise Asset Management Command Center enables increased asset reliability while reducing

operational costs, and improves the visibility of key focus areas that enable Enterprise Asset

Management supervisors to take quick actions in asset maintenance. You can use the Enterprise Asset

Command Center to:

• Maximize asset availability:

o Analyze asset performance metrics.

o Identify recurring failures and expedite resolution.

• Prioritize work order exceptions:

o Adjust resource scheduling to avoid schedule delays and cost overruns.

• Respond quickly to material shortages:

o View spare part requirements and usage trends.

o Prioritize critical work orders and update material allocations to resolve out-of-stock

conditions.

The Enterprise Asset Management Command Center improves the visibility of key focus areas, enabling

Enterprise Asset Management supervisors to take quick actions in asset maintenance.

Searching Enterprise Command Center Dashboards

Use the dashboard sidebar to refine (filter) the data on each dashboard. You can also Search using a

keyword, value, or a specific record. You can also search using Descriptive Flexfield (DFF) attributes for

the following dashboards:

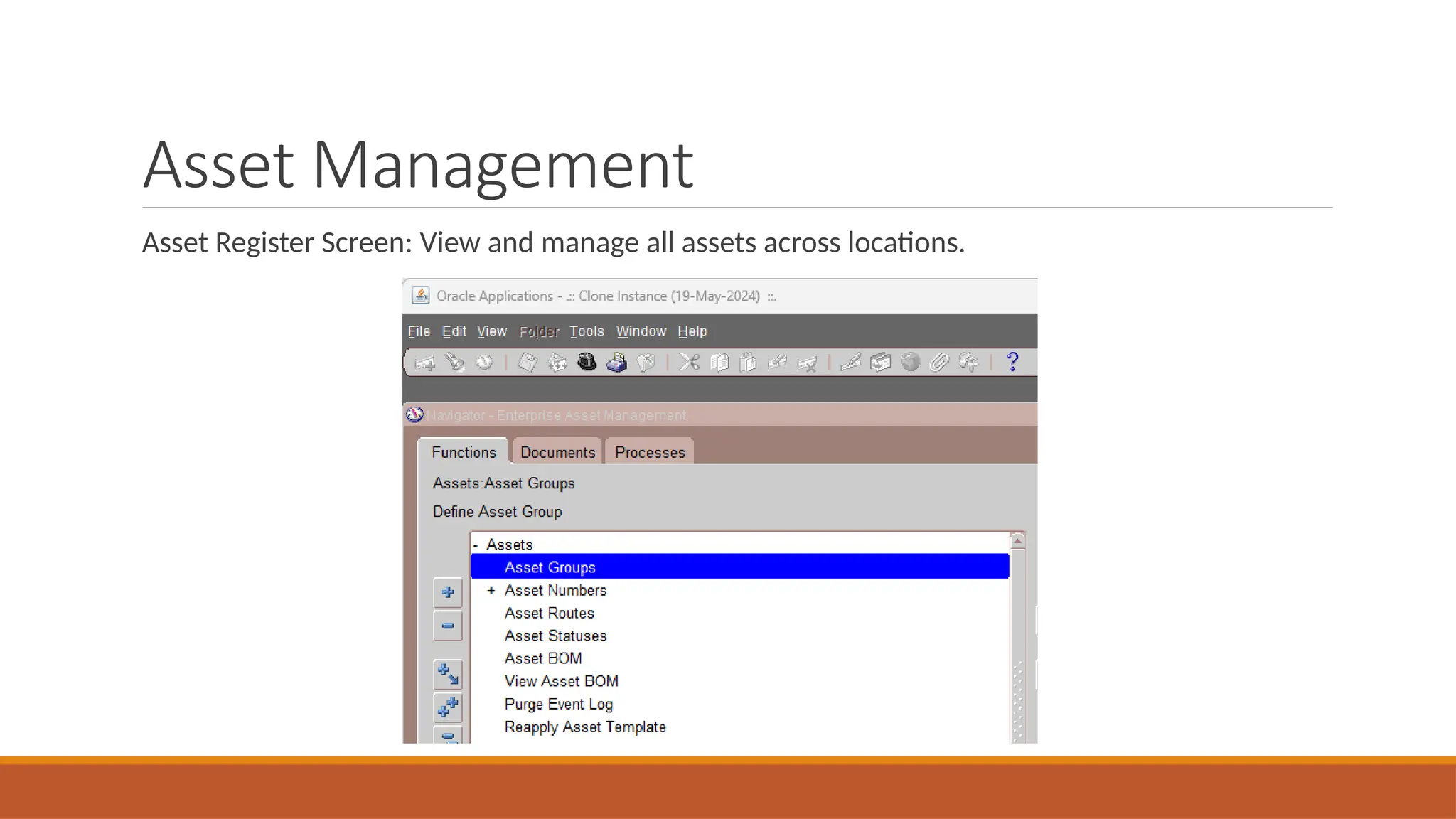

• Assets Dashboard - Available Refinements: Asset Attributes, Item Instance Flexfield Details

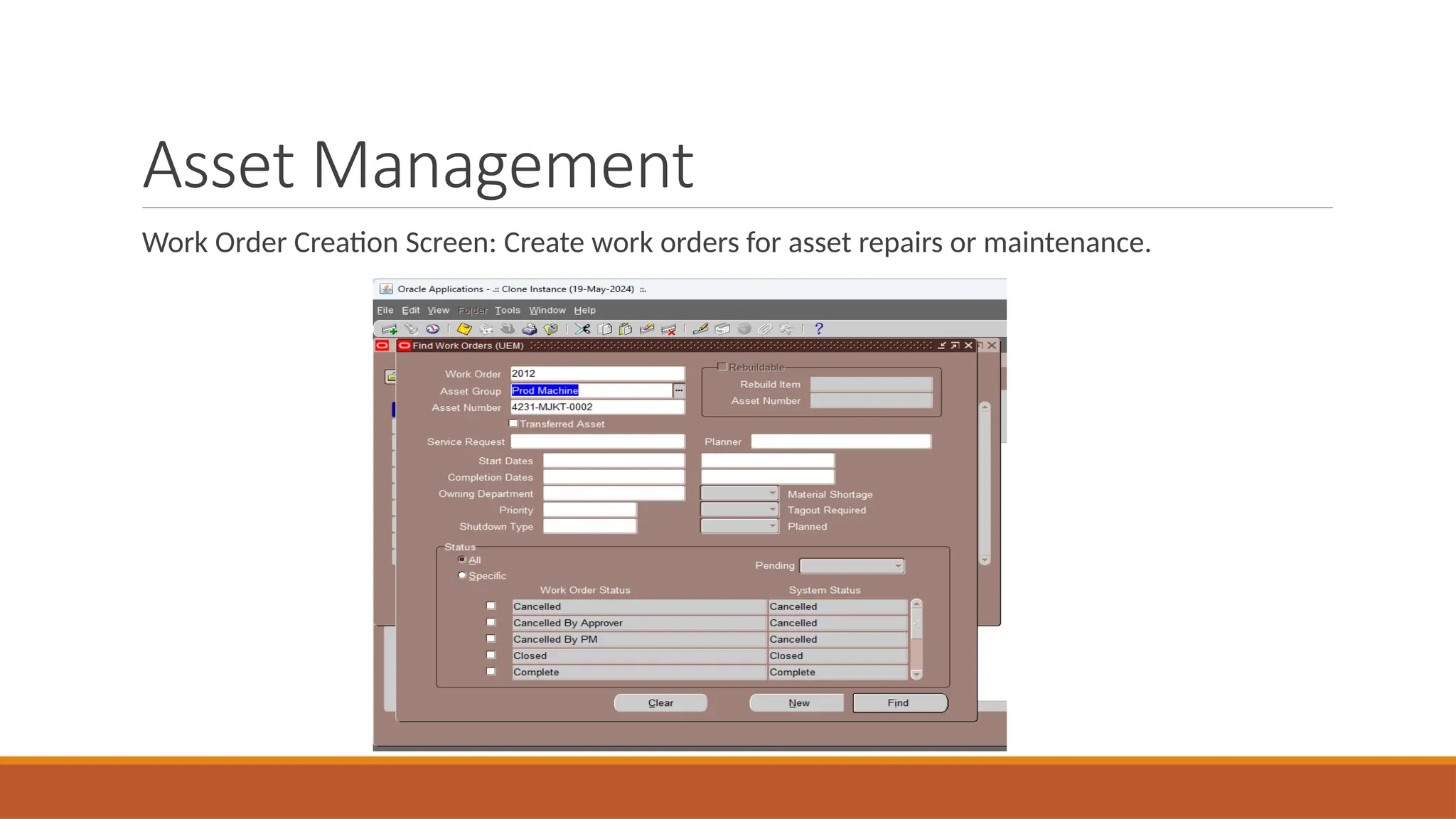

• Open Work Orders Dashboard - Available Refinement: Work Order Flexfields

• Materials Dashboard - Available Refinement: Component Information Flexfields

In certain dashboards, you can further refine information by searching multiple data sets at once. From

the Available Refinements component, click the Options icon and select data sets for the following

dashboards:

• Assets Dashboard - Assets, Asset Attributes, Work Order Assets, Asset Attributes, Collection

Results

• Open Work Orders Dashboard - Work Orders, Work Requests, Collection Results

• Materials Dashboard - Stores Materials, Stores Work Order, Inventory On-Hand

The type-ahead feature suggests matches for your entry that correspond to the selected data set. When

you submit a search, the search term is added to the Selected Refinements list, and the dashboard data

is refined to include only records that match the search. You can add multiple refinements and remove

any of them at any time. Using Saved Searches, you can create and save your searches and refer to them

later. You can also edit and delete saved searches.

Use an asterisk (*) or percent sign (%) to perform a partial keyword or record search that matches any

string of zero or more characters. You can also use a question mark (?) to perform a partial search that

matches any single character.

Assets Dashboard

Use the Assets Dashboard to analyze metrics and refine asset performance. Using the Assets

Dashboard