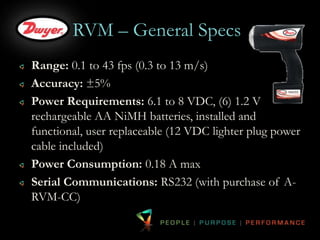

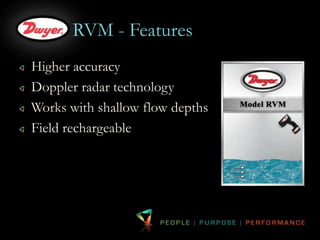

The document provides an overview of open channel flow panel meters developed by Dwyer Instruments, Inc., detailing various products that utilize Doppler radar and ultrasonic technology for accurate flow and level measurements. Each product, including specifications, features, and applications, is designed for specific environments such as wastewater facilities and river flow measurement. Usage guidelines emphasize that proprietary company materials are not to be reproduced without permission.