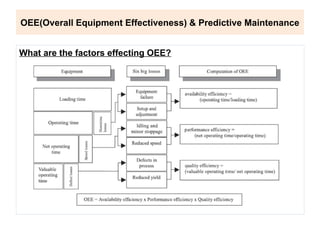

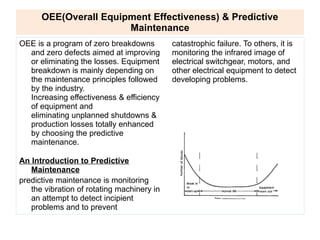

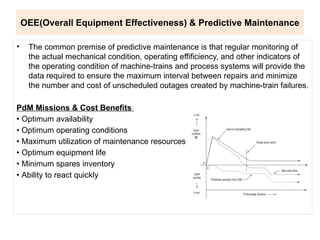

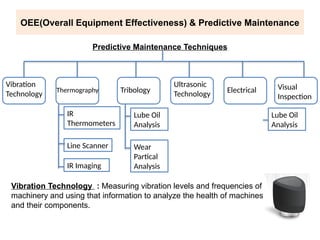

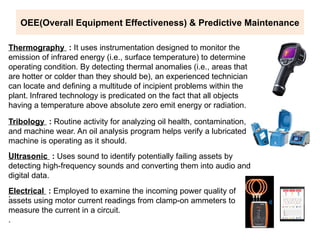

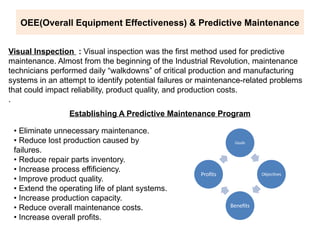

Overall Equipment Effectiveness (OEE) is a KPI for measuring productivity in manufacturing, focusing on asset availability, performance, and quality, with a world-class benchmark of 85%. Factors affecting OEE include unplanned downtimes, speed losses, and quality losses, with predictive maintenance techniques like vibration analysis and thermography helping to minimize these issues. Establishing a predictive maintenance program aims to enhance efficiency, reduce costs, and improve equipment life, ultimately supporting OEE improvements.