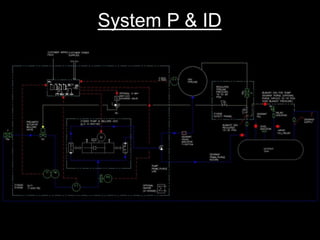

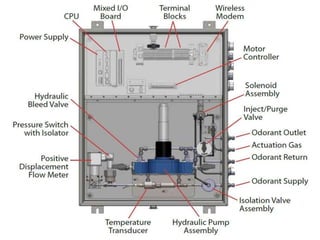

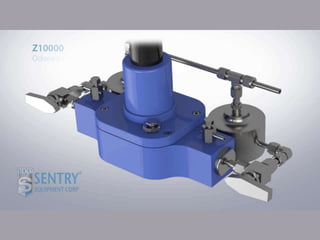

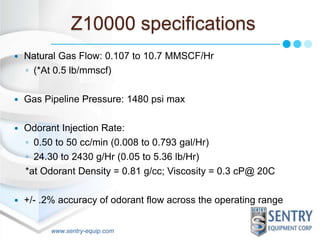

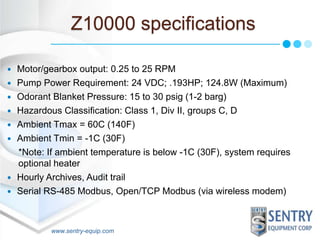

The Sentry Z10000 odorant injection system design meets the demands for accurately injecting odorants into natural gas transmission lines, handling flow rates up to 10 mmscf/hr and pressures up to 1480 psig. It features a metal bellows pump for infinite cycle life, minimal gas entrainment, and extensive monitoring capabilities. The system is maintenance-friendly and operates in a closed-loop to prevent exposure to atmosphere.