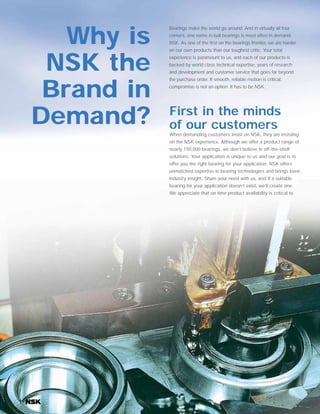

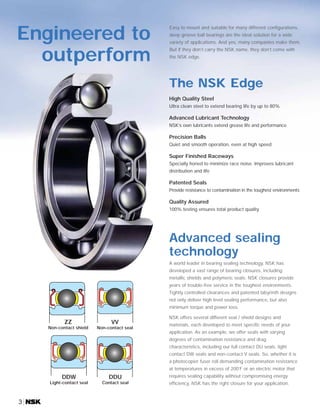

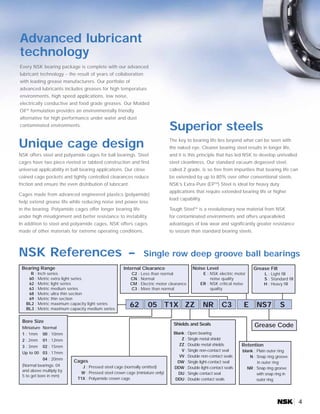

NSK produces deep groove ball bearings that offer outstanding performance in a wide range of applications. NSK prides itself on providing customized bearing solutions and high quality products, ensured by rigorous testing. Key aspects of NSK's bearings include advanced steel, lubrication, sealing technologies, and a focus on meeting unique customer needs.