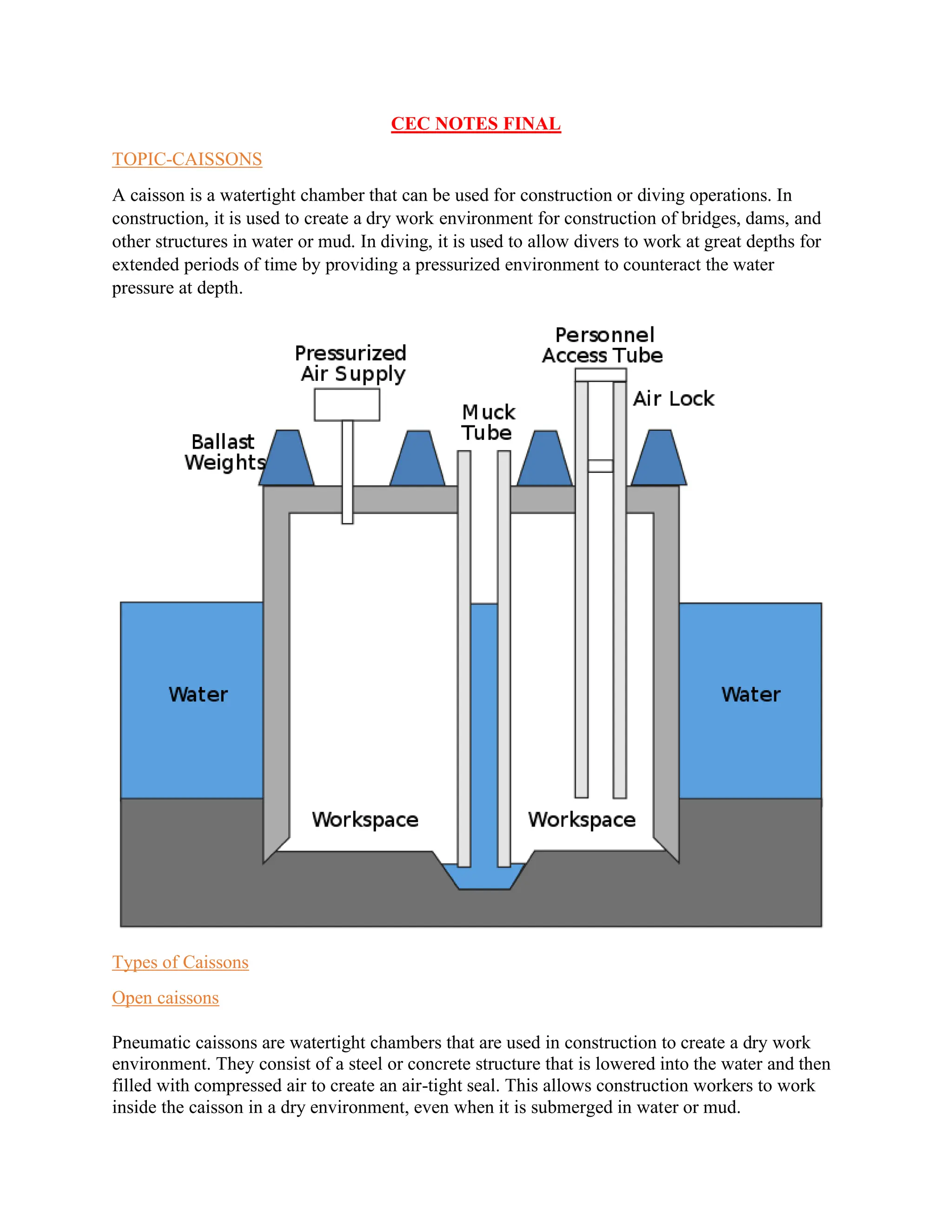

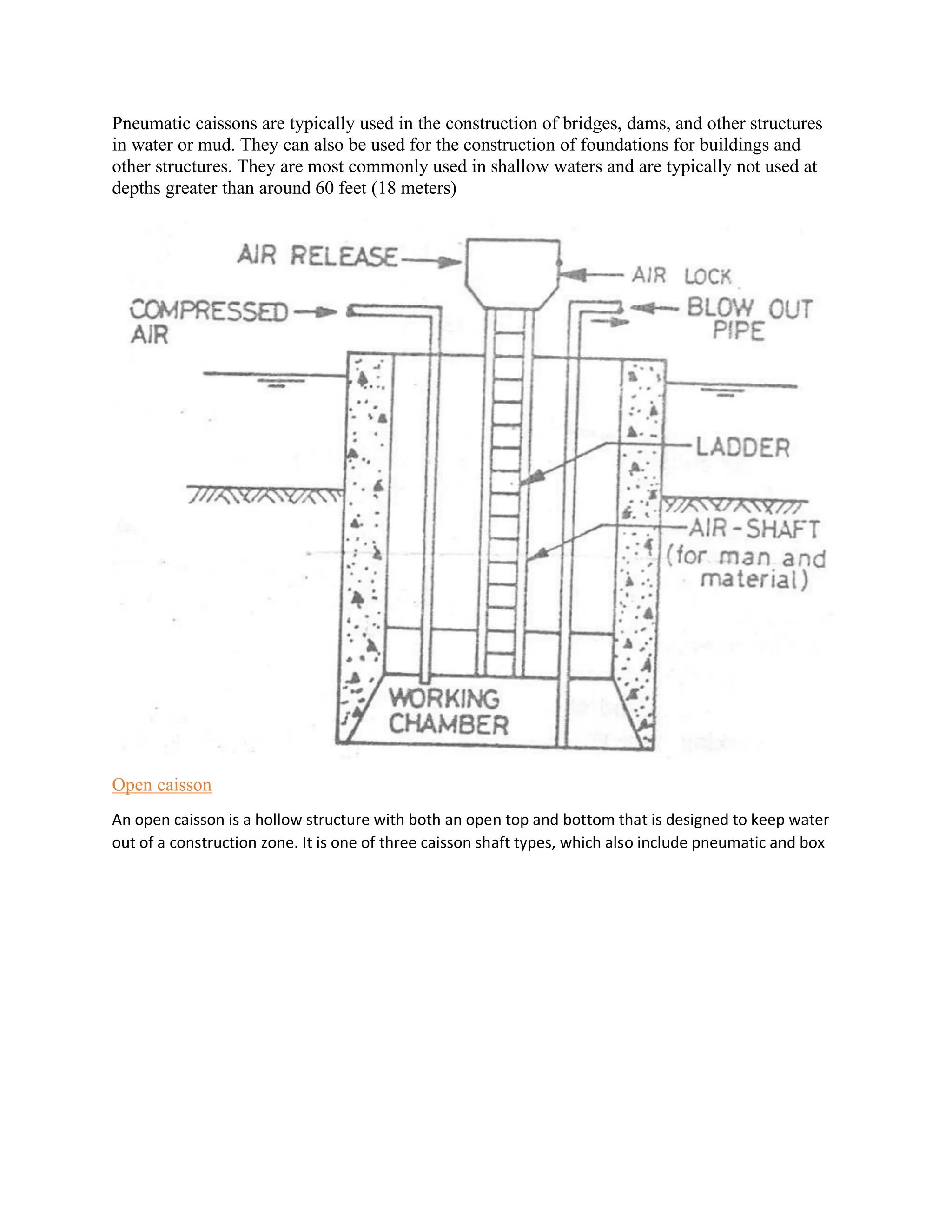

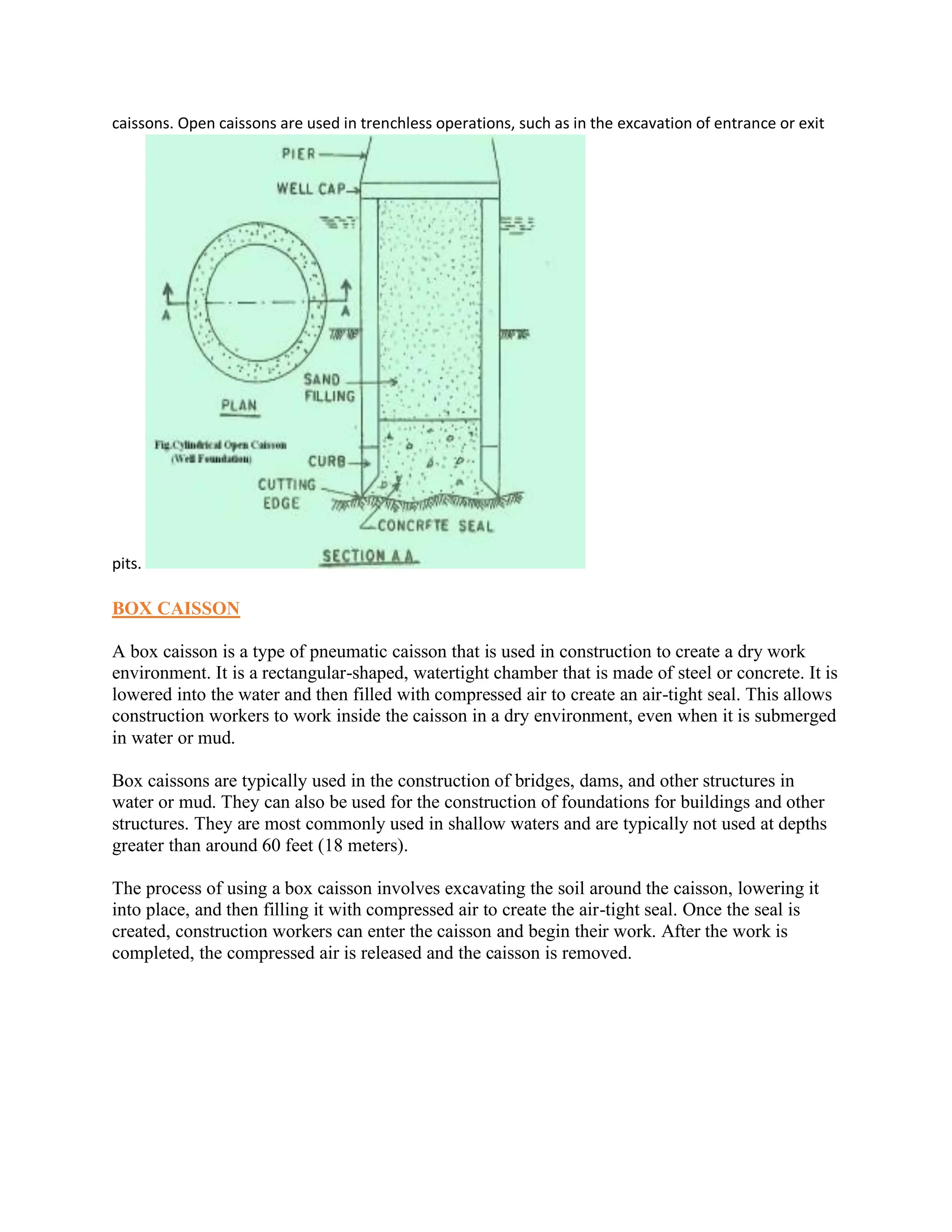

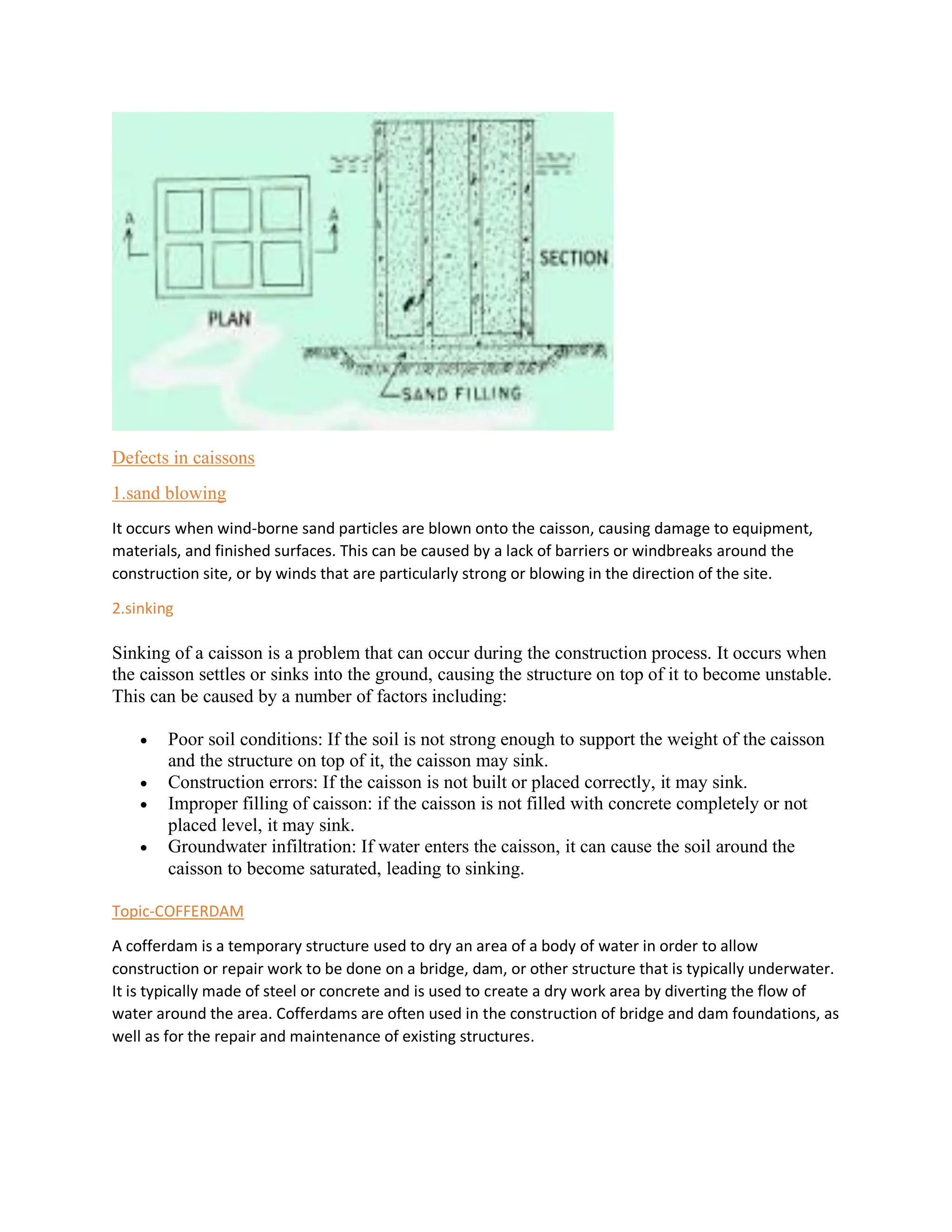

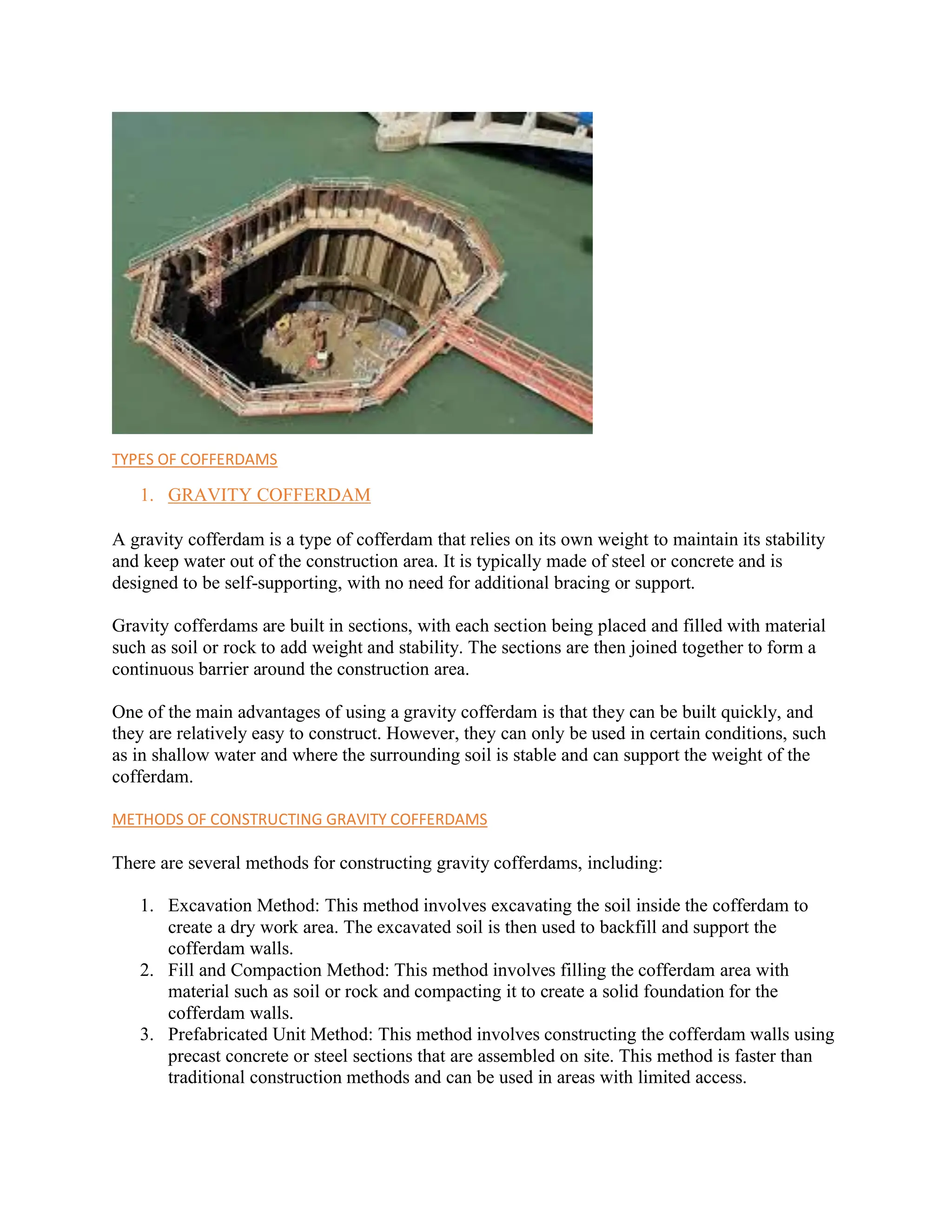

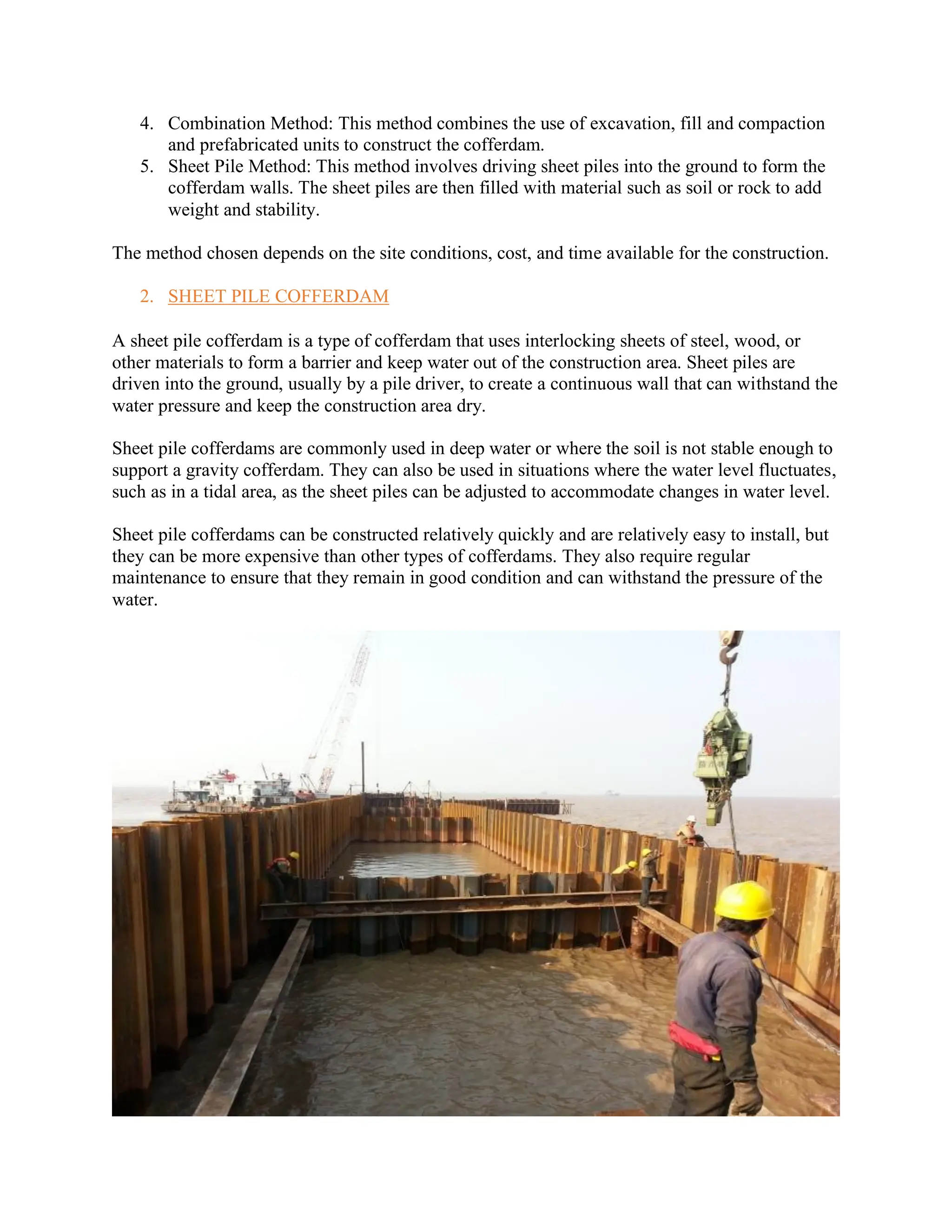

Caissons are watertight chambers used in construction and diving. In construction, they create a dry work environment under water or mud for bridges, dams, and other structures. There are three main types of caissons - open, pneumatic, and box - each used in different construction applications. Pneumatic caissons are most common, using compressed air to create a dry interior. Defects like sinking can occur if not properly constructed. Cofferdams are temporary structures that divert water flow to create a dry work area. Common types are gravity, sheet pile, and arch cofferdams, built using different materials and methods depending on site conditions. Dredging removes sediment to deepen waterways