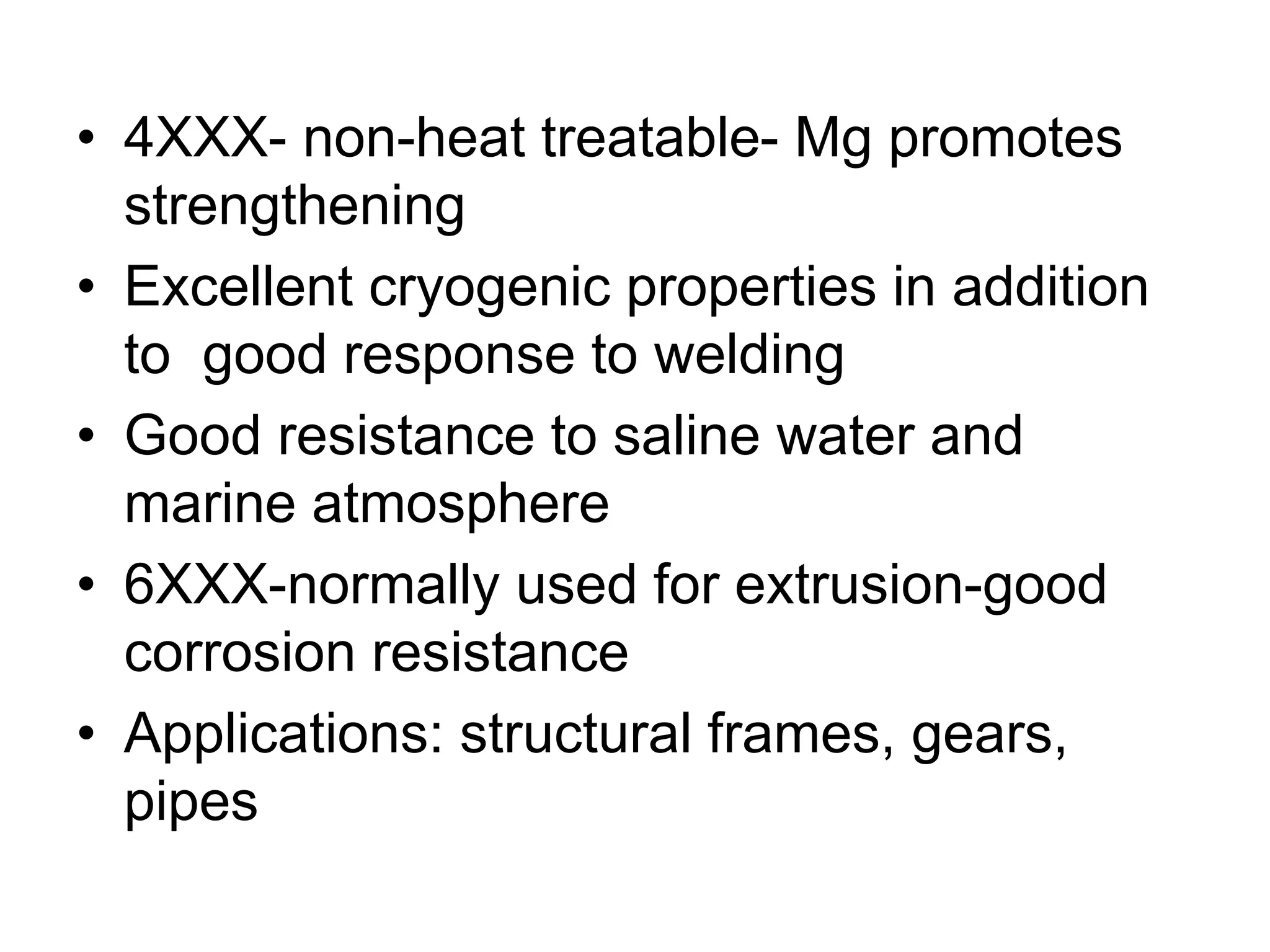

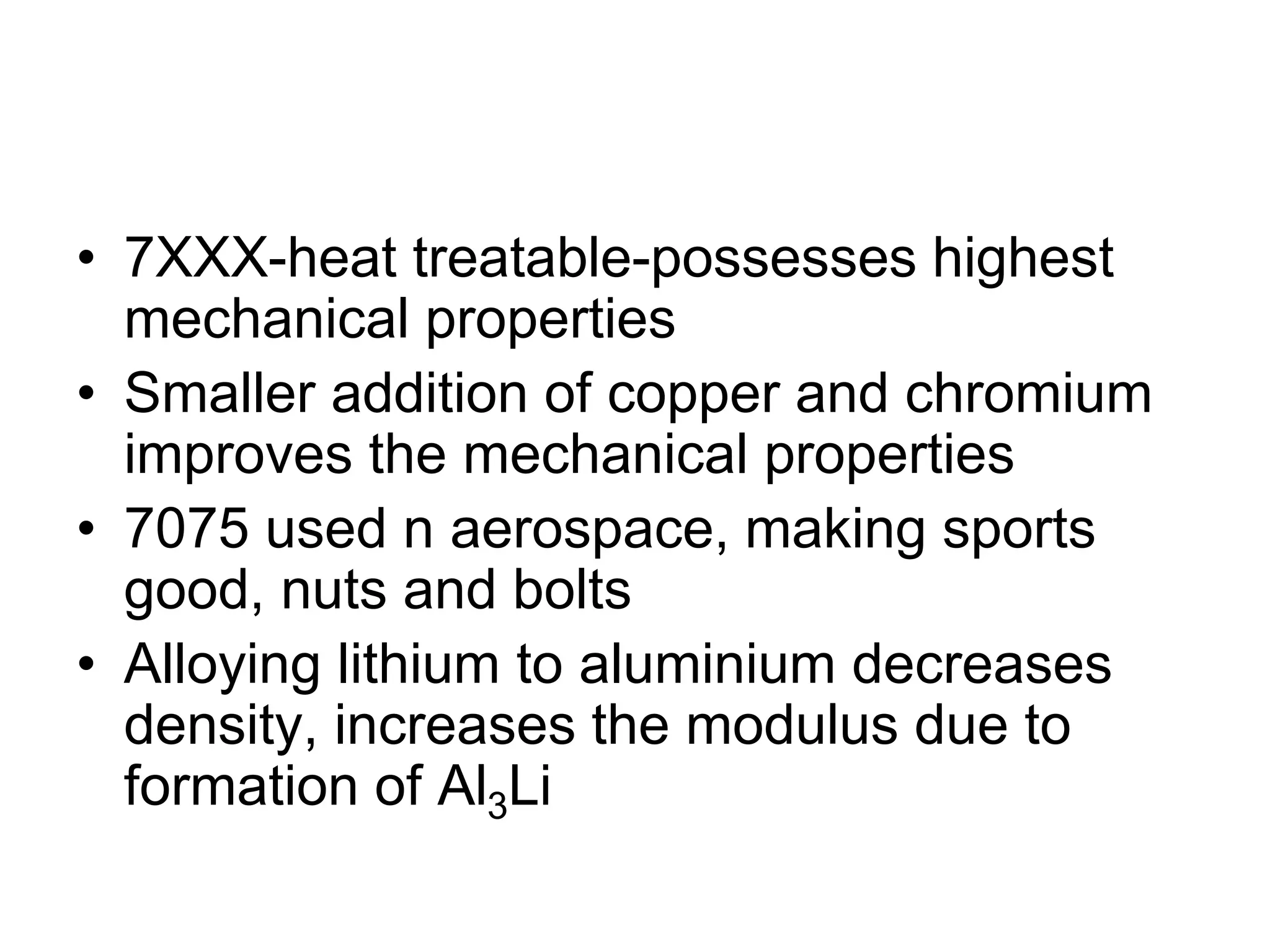

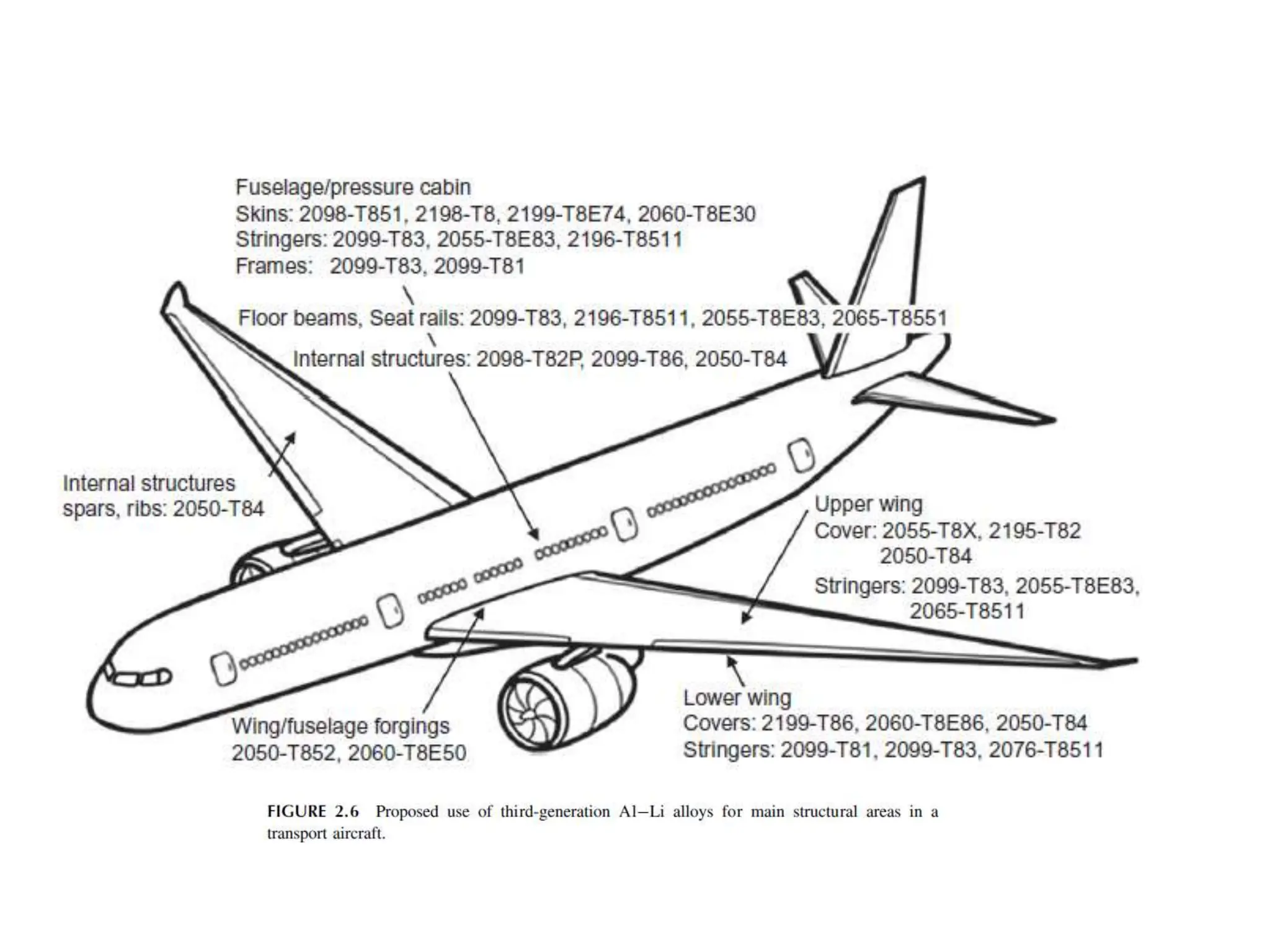

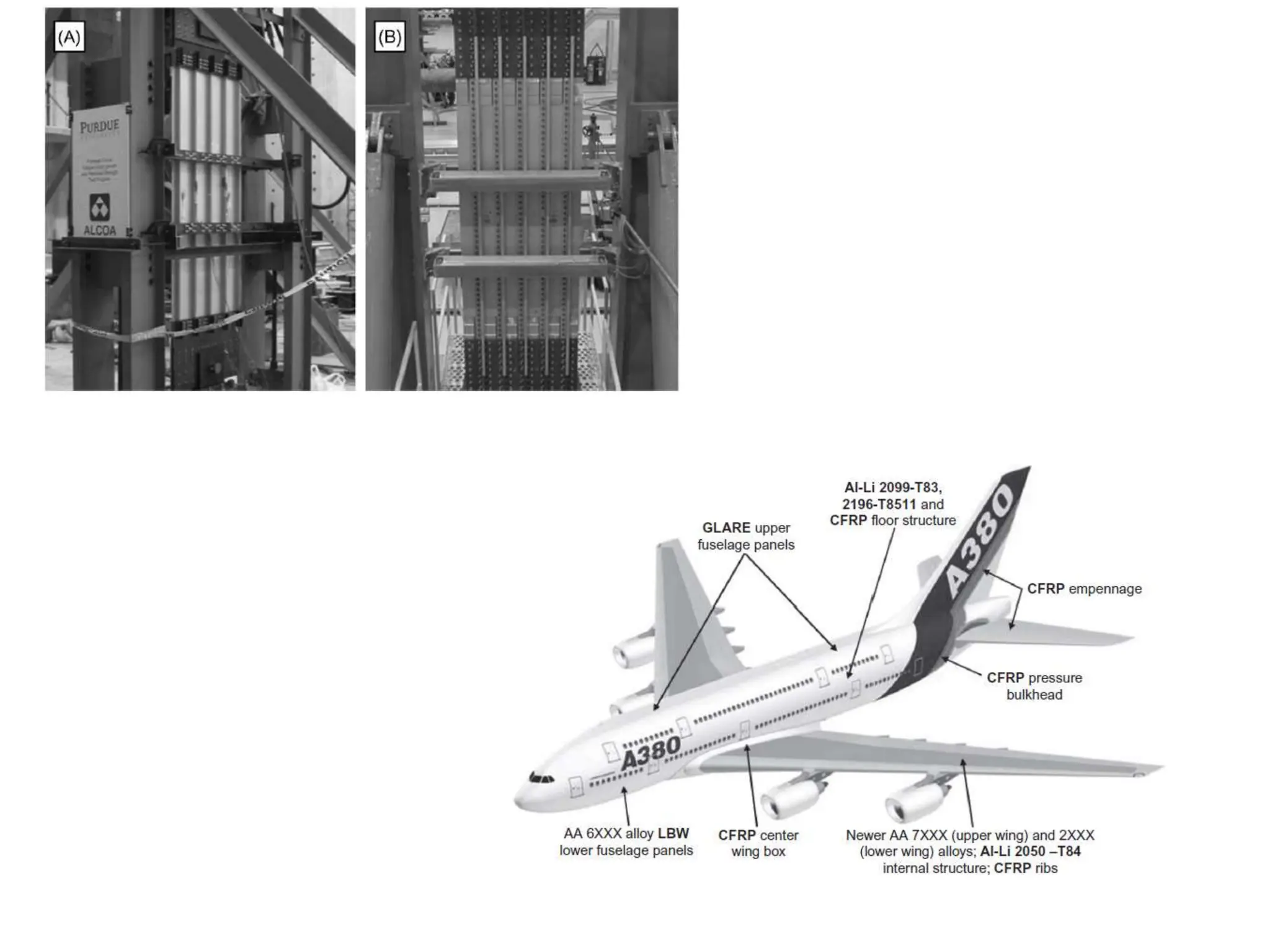

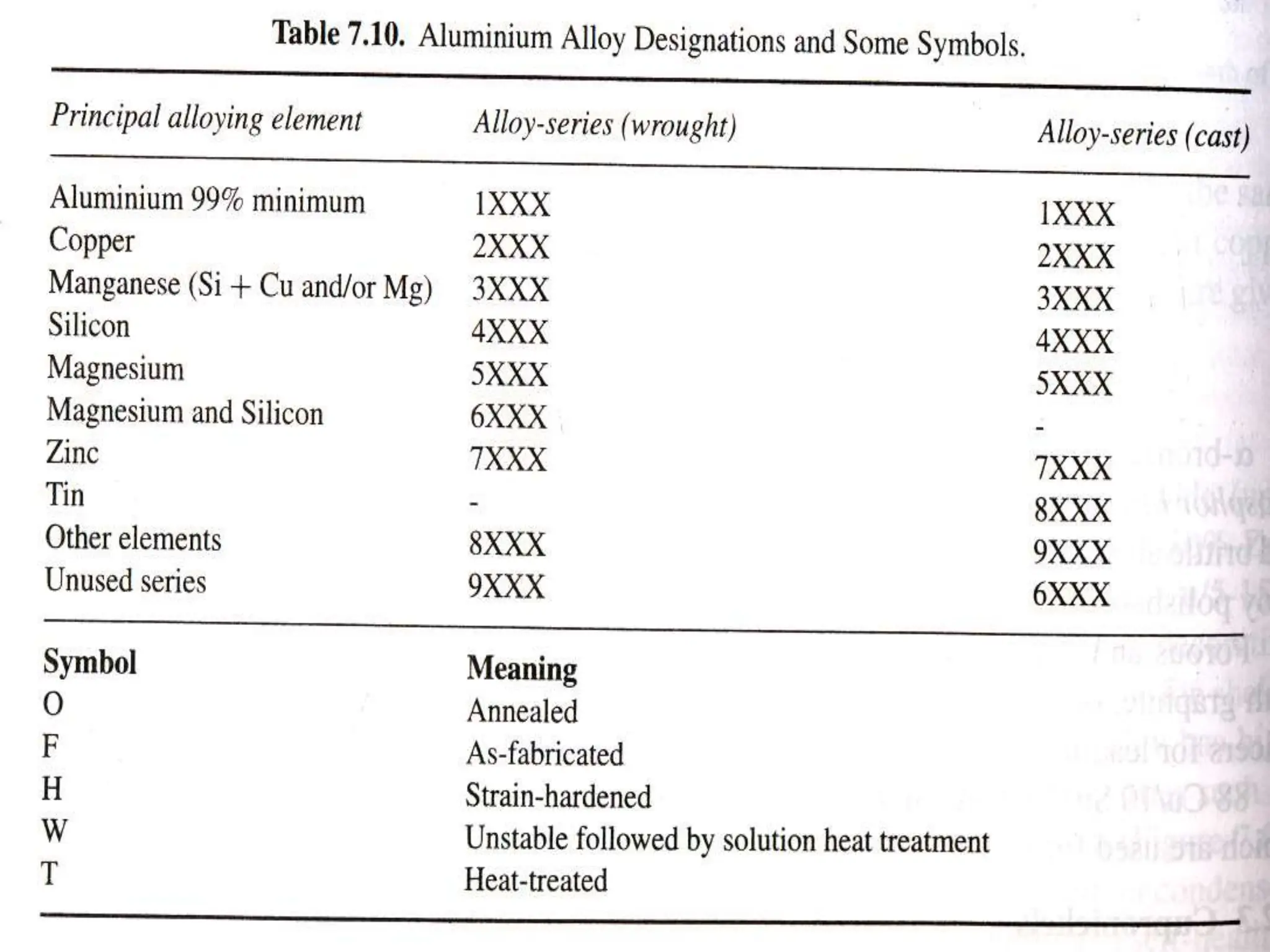

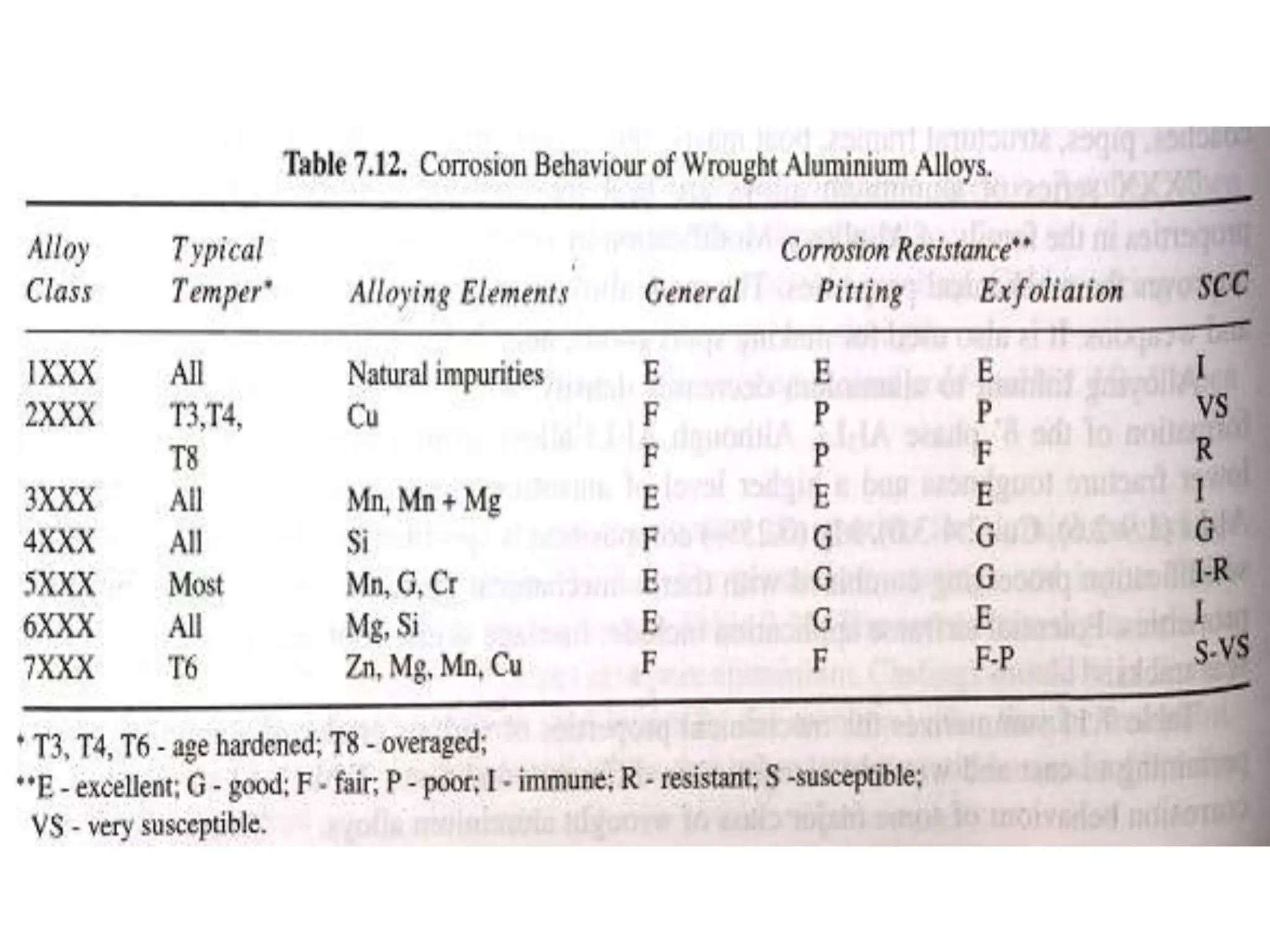

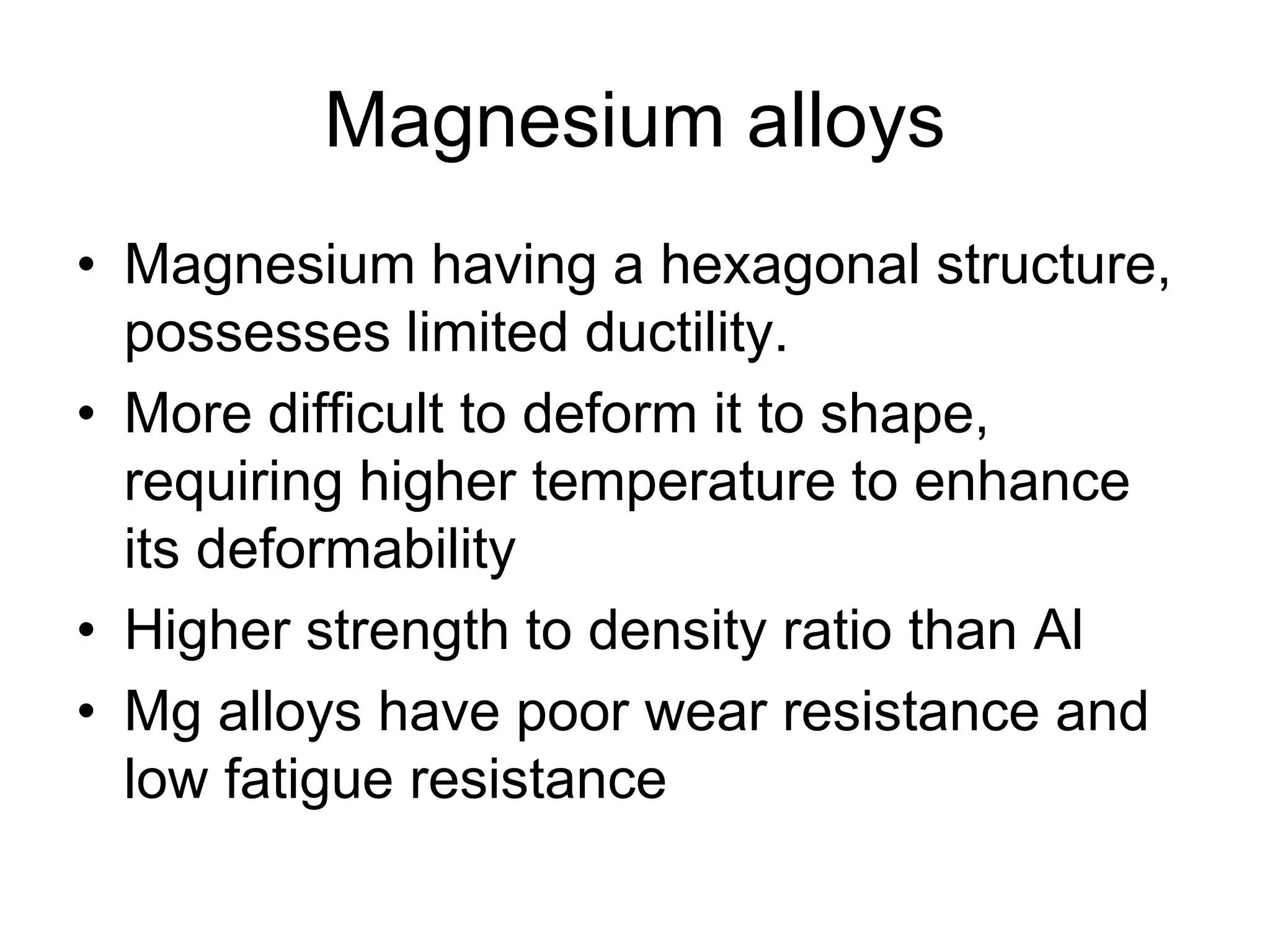

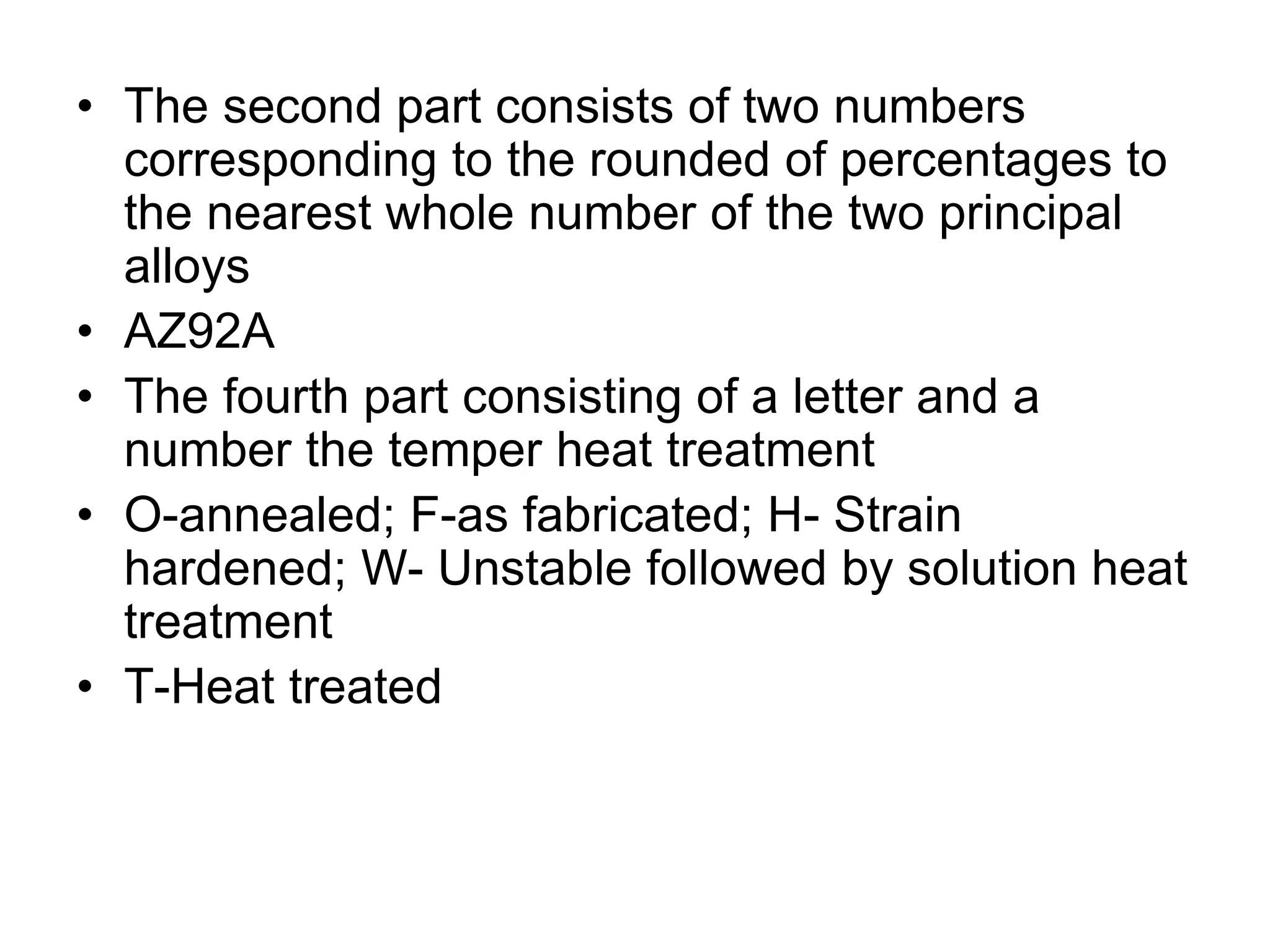

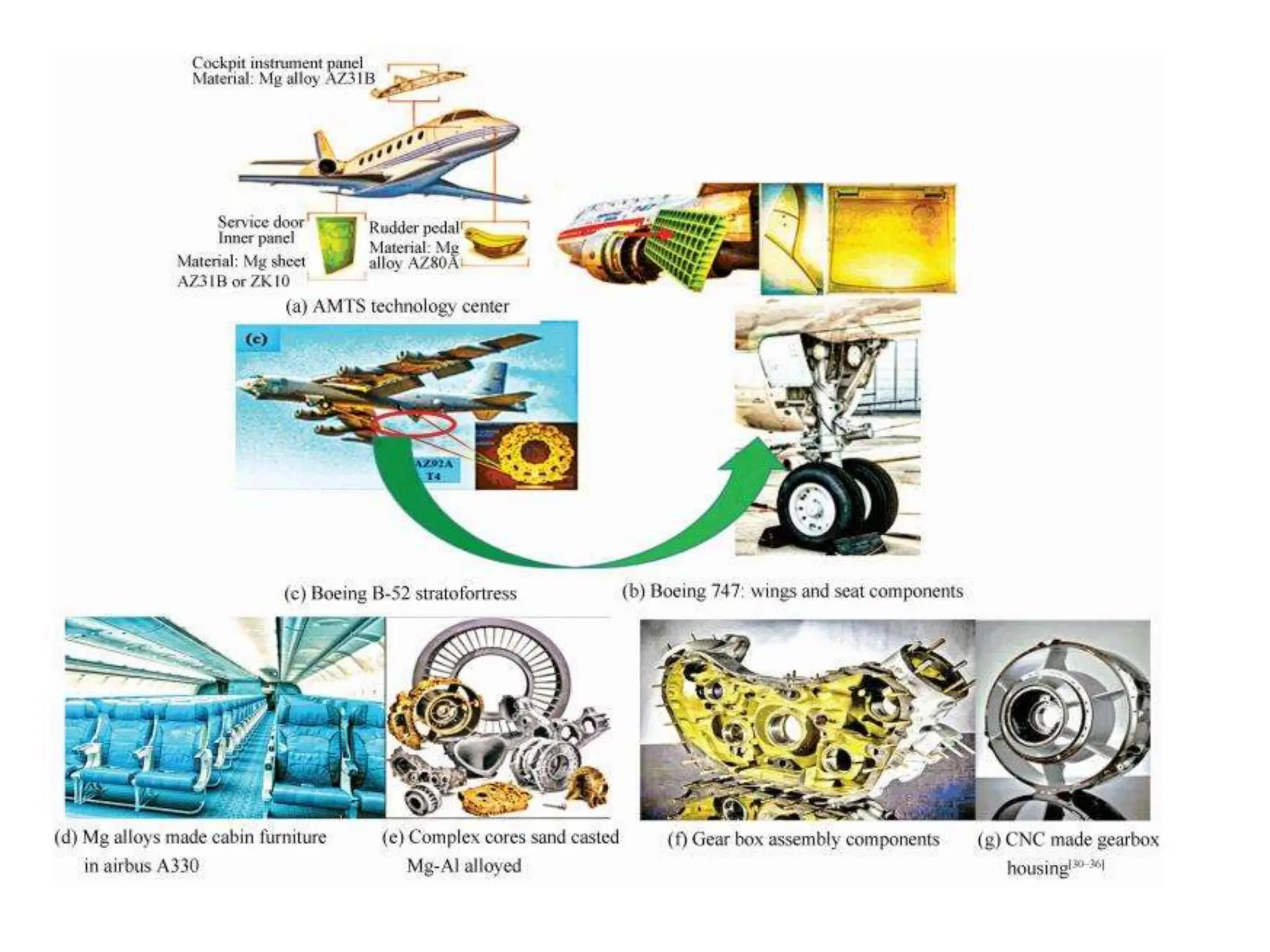

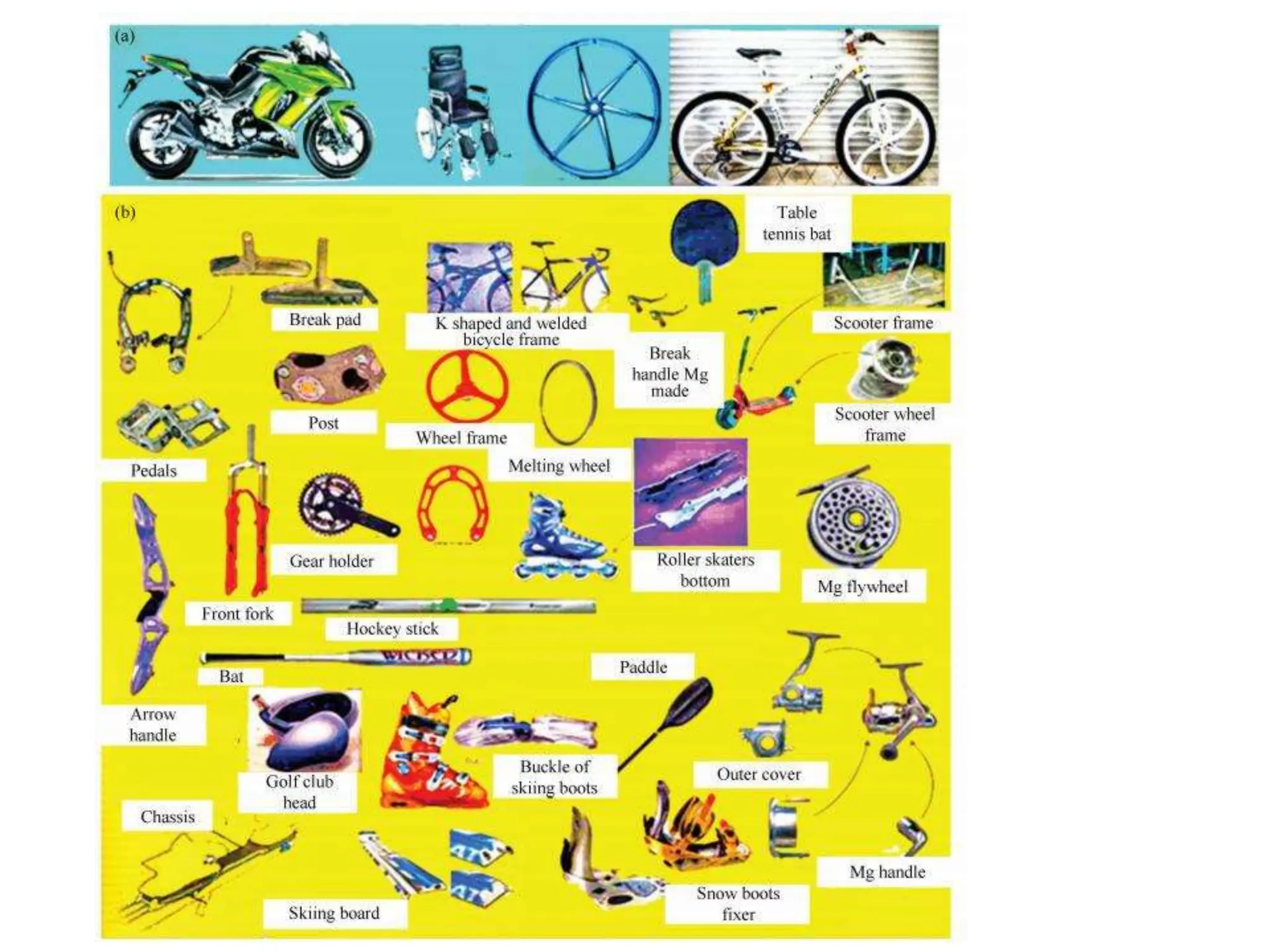

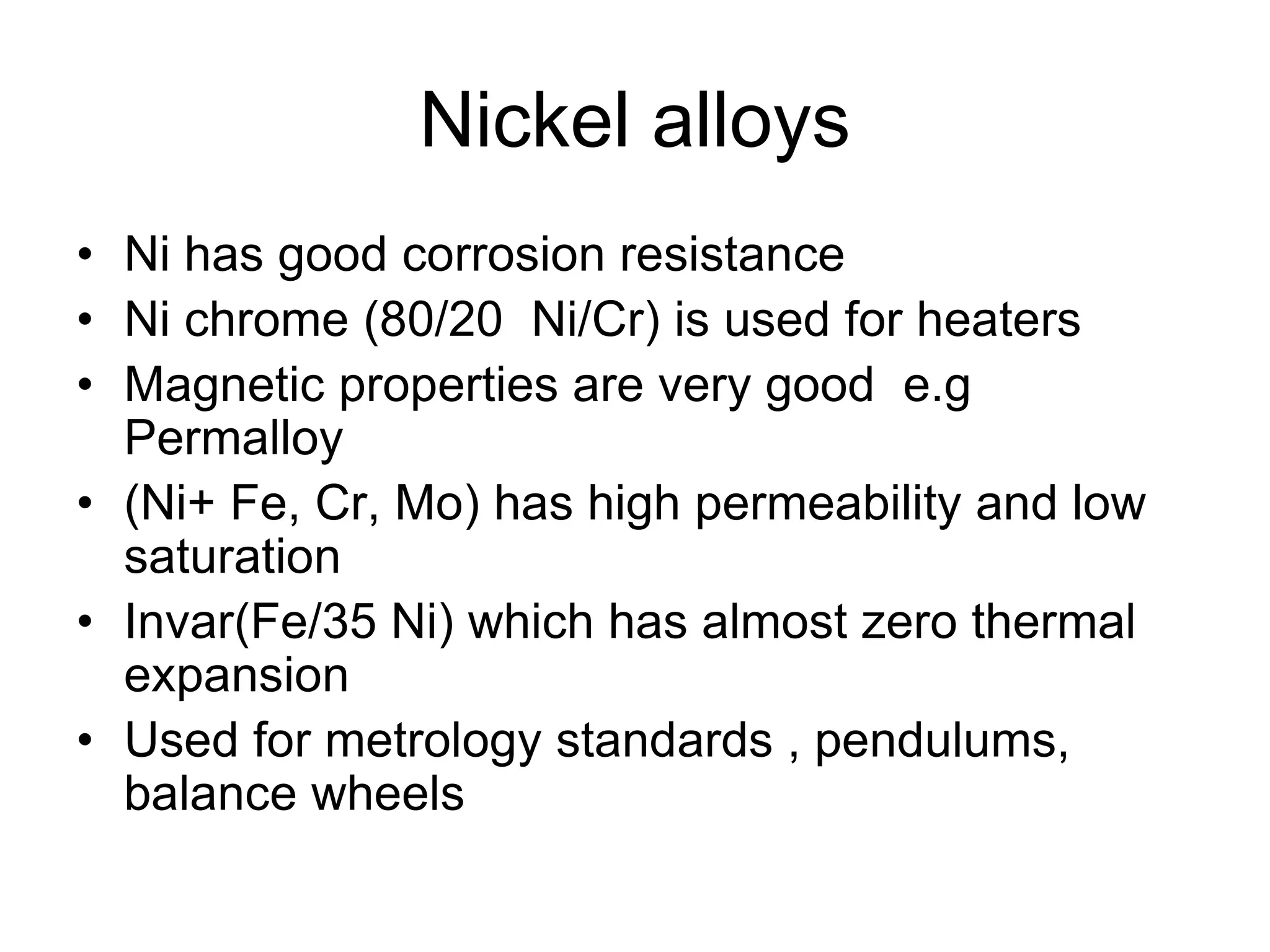

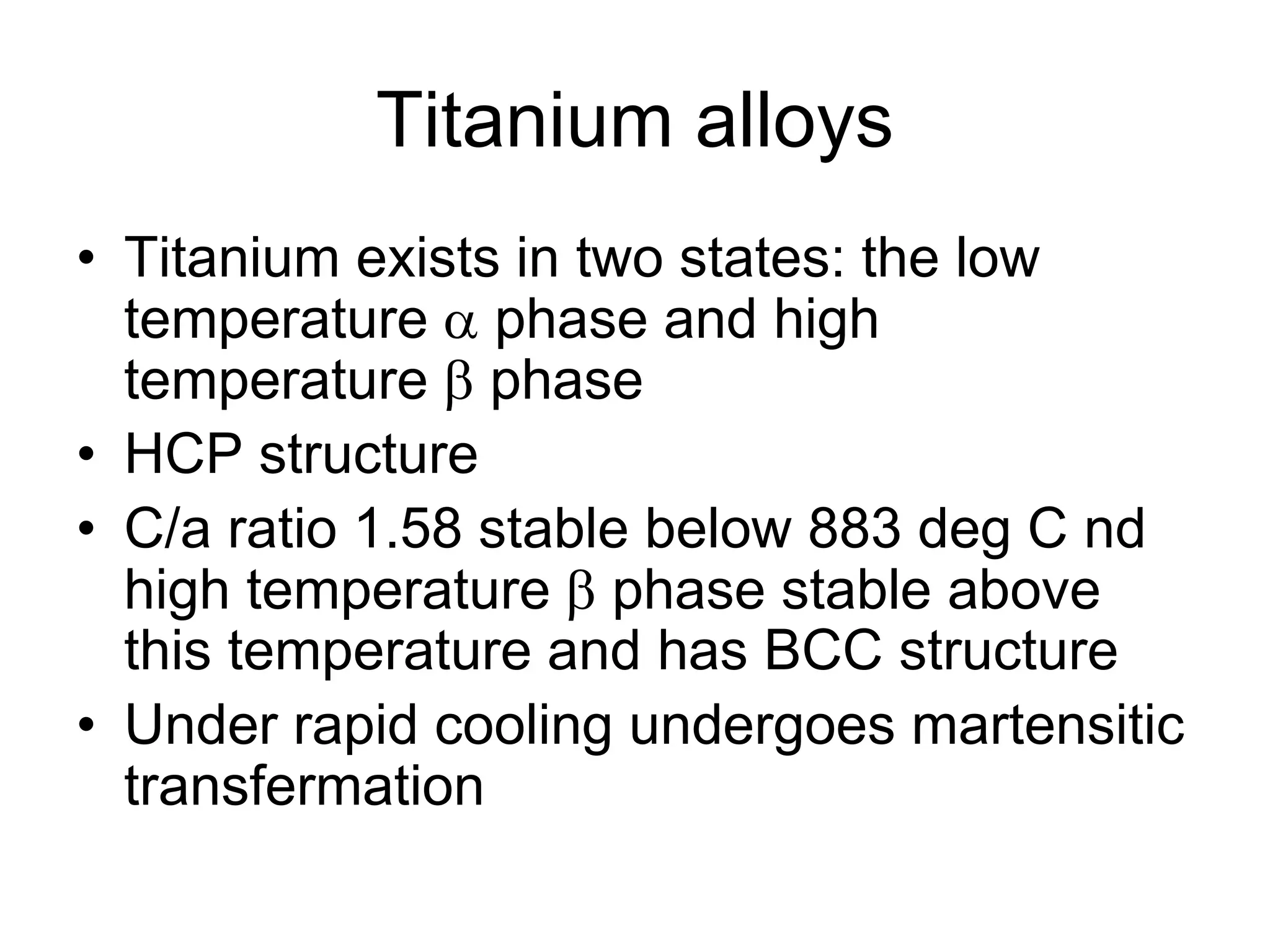

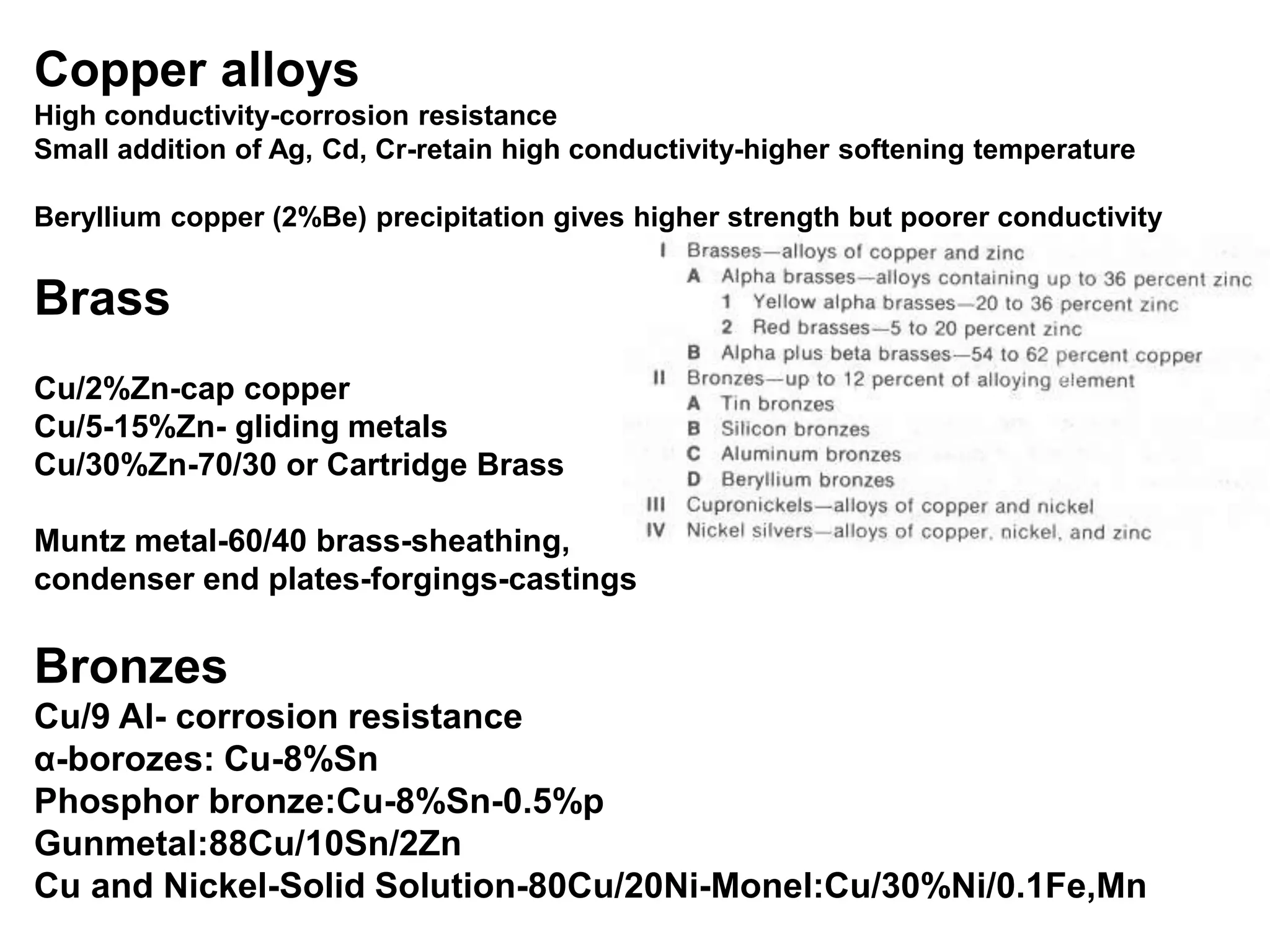

This document discusses various metal alloys, including their compositions, properties, designations, and applications. It covers aluminium alloys, magnesium alloys, nickel alloys, titanium alloys, and copper alloys. Key points include the lightweight and corrosion resistant properties of aluminium alloys, magnesium alloys having higher strength to density than aluminium but poorer ductility, nickel alloys being used in gas turbine blades due to high strength and corrosion resistance at high temperatures, and copper alloys having high conductivity.

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-38-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-39-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-40-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-41-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-42-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-43-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-44-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-45-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-46-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-47-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-48-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-49-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-50-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-51-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-52-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-53-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-54-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-55-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-56-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-57-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-58-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-59-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-60-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-61-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-62-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-63-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-64-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-65-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-66-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-67-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-68-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-69-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-70-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-71-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-72-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-73-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-74-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-75-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-76-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-77-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-78-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-79-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-80-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-81-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-82-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-83-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-84-2048.jpg)

![non_ferrous_alloys[10].ppt](https://image.slidesharecdn.com/nonferrousalloys1-231219170543-d4873726/75/non_ferrous_alloys-10-ppt-85-2048.jpg)