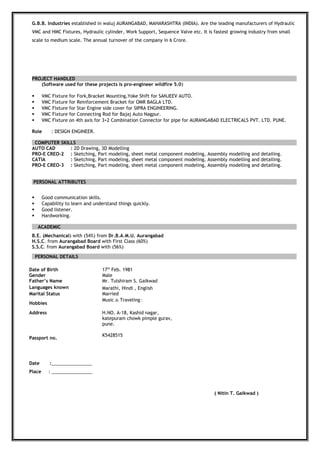

Nitin Gaikwad is a design engineer with over 5 years of experience in modeling, assembly design, detailing, and fixture design using Pro-E, Creo, Catia, and UGNX. He currently works at Onward Technologies as a design engineer, where he has designed various fixtures for automotive clients like John Deere, General Motors, and Honda. Previously, he worked at G.B.B. Industries designing VMC and HMC fixtures using Pro-E. He aims to utilize his skills in modeling, assembly design, and understanding of manufacturing processes to benefit an organization.