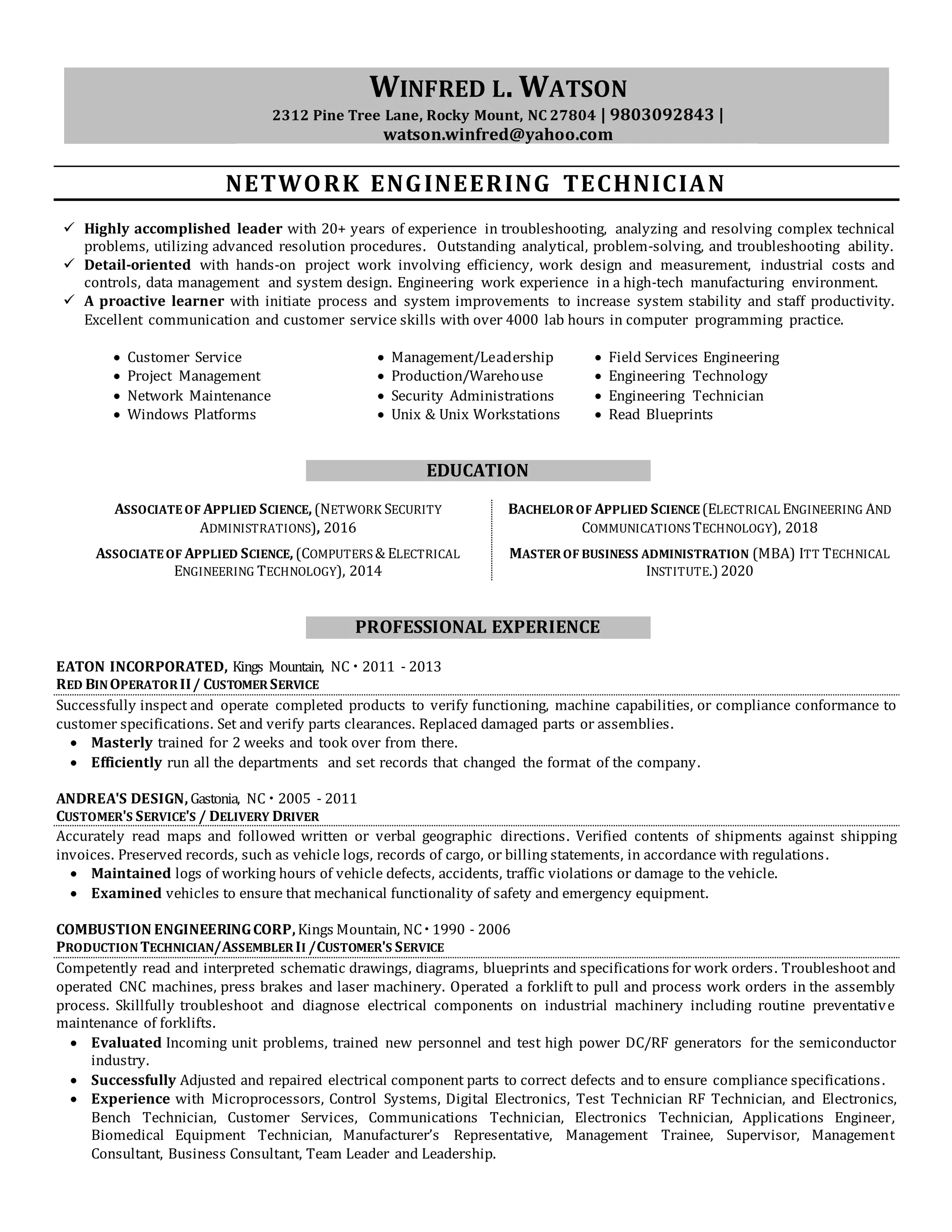

Winfred L. Watson has over 20 years of experience in network engineering and troubleshooting technical problems. He is detail-oriented and has worked in engineering roles in manufacturing environments. Watson is a proactive learner who seeks to improve systems and increase productivity. He has an Associate's degree in Network Security Administration and Computers & Electrical Engineering, a Bachelor's degree in Electrical Engineering and Communications Technology, and a Master's in Business Administration.