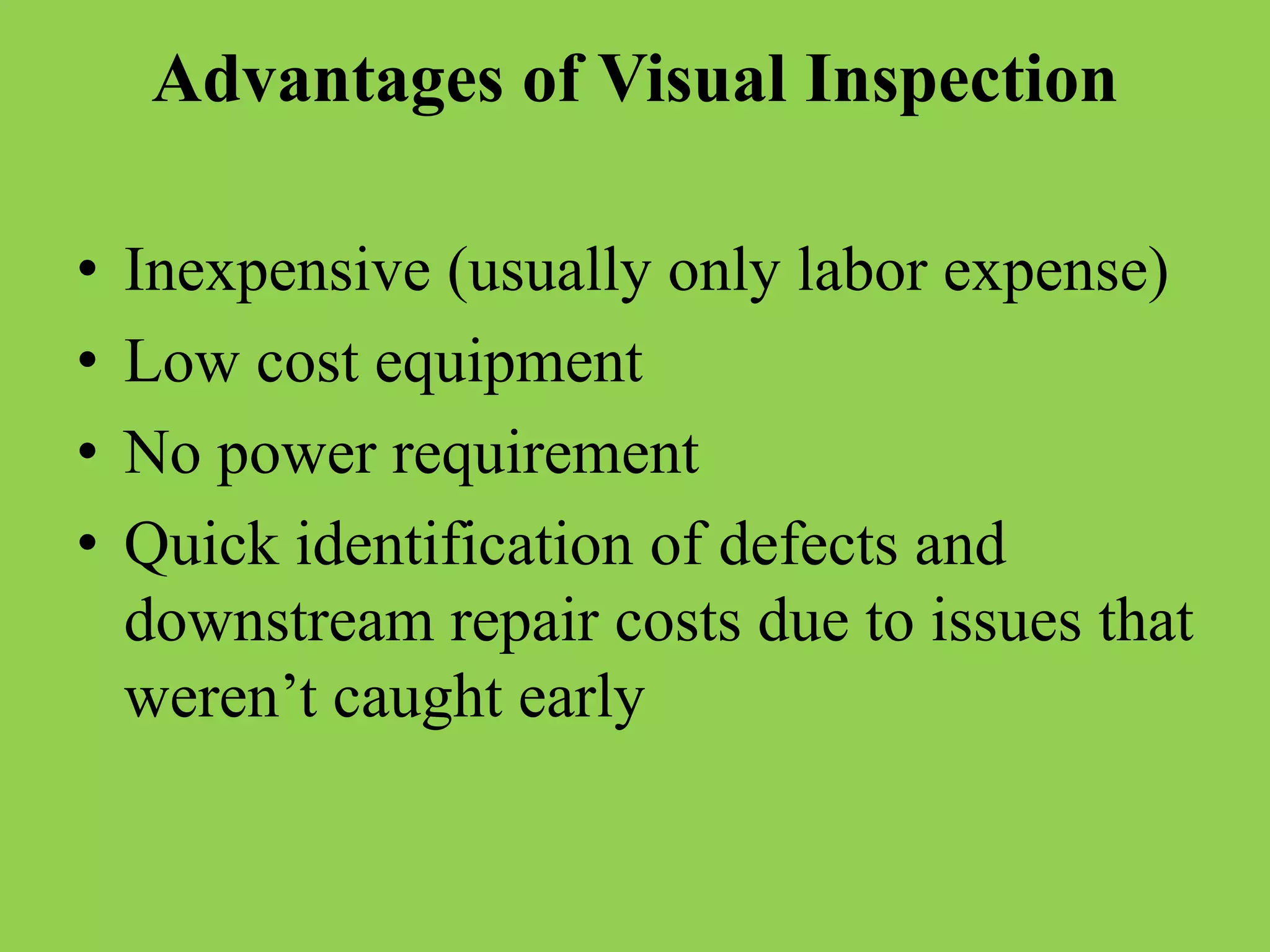

Visual inspection (NDT) is an economical non-destructive testing method that involves visual examination of weld joints to check integrity and soundness. It requires a well-trained inspector to check for code compliance, workmanship, and documentation at various stages including before, during, and after welding. Visual inspection can identify surface defects but has limitations as it cannot detect internal flaws and requires inspector skill and documentation.