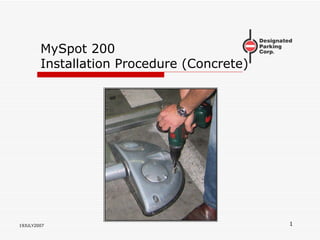

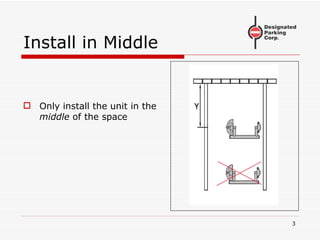

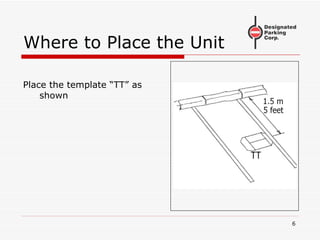

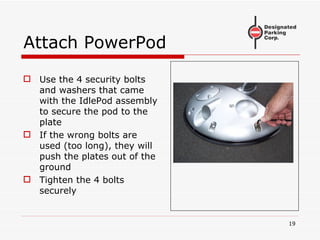

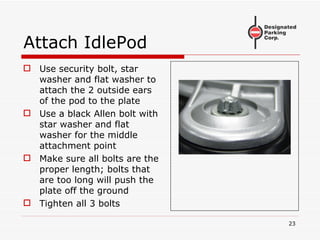

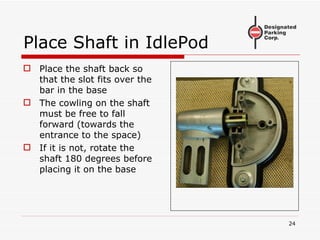

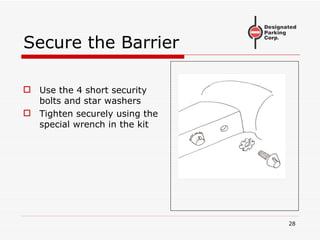

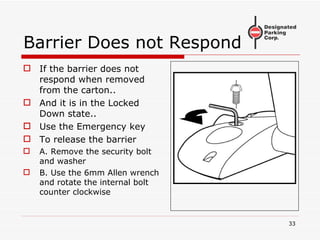

The document provides step-by-step installation instructions for a MySpot 200 parking barrier system on a concrete surface. It details locating and preparing the installation site, unpacking and identifying parts, drilling anchor holes, inserting anchors, aligning and securing mounting plates, attaching the barrier and pod units, testing functionality with remote controls, and troubleshooting tips.