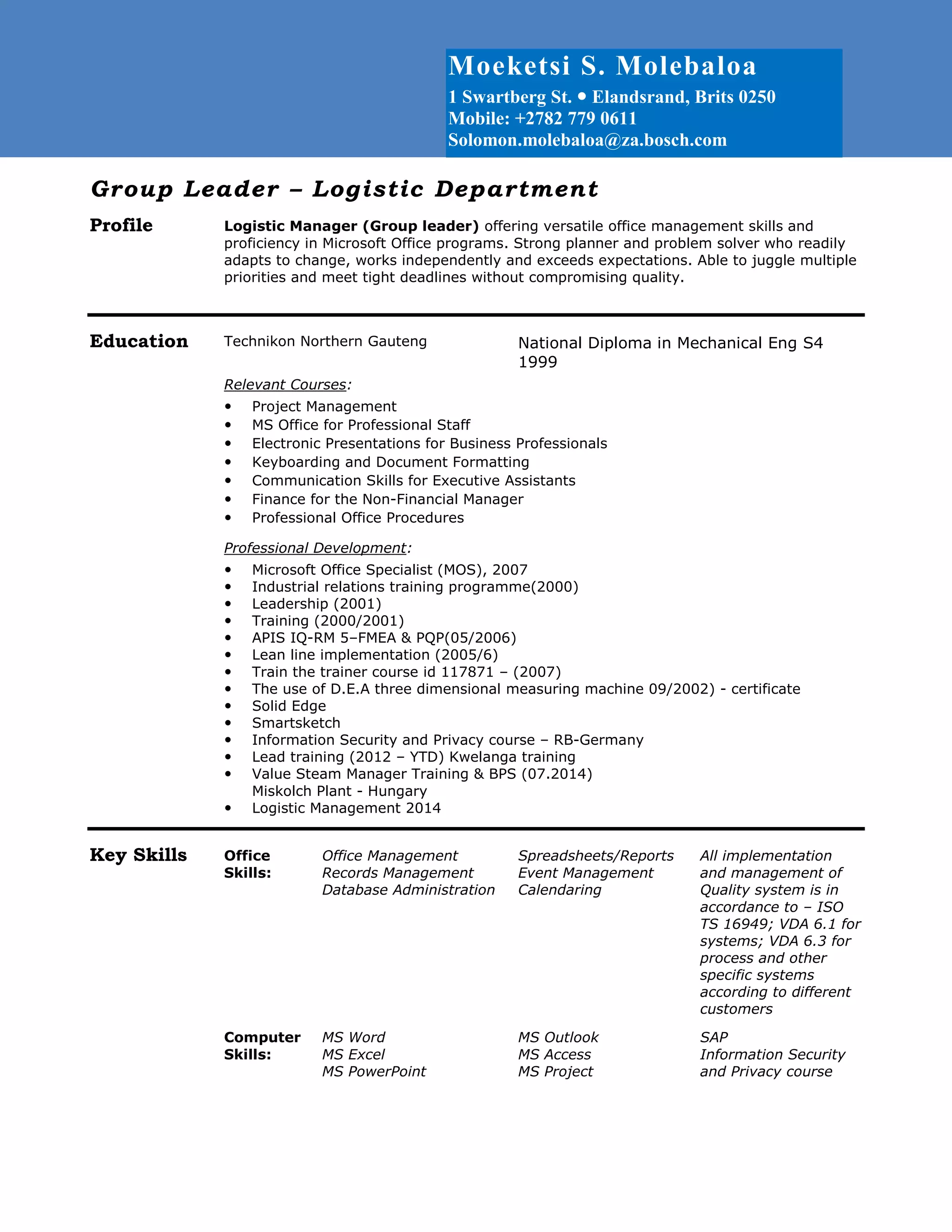

This document summarizes the qualifications and experience of a logistic manager group leader. The candidate has over 15 years of experience managing logistics, quality, and production departments at Robert Bosch SA. He holds a National Diploma in Mechanical Engineering and has extensive training in areas such as leadership, project management, quality systems, and Microsoft Office programs. Currently he is managing the logistic department warehouse and value stream at Robert Bosch SA.