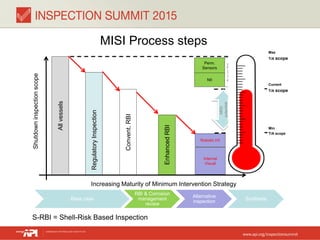

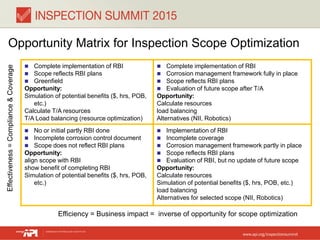

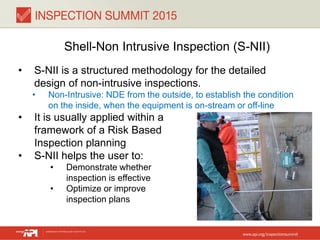

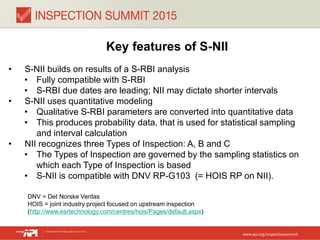

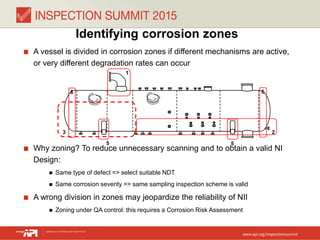

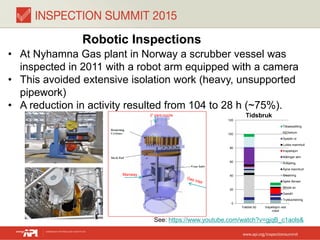

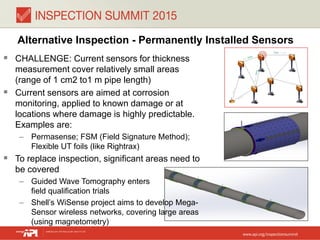

The document discusses Shell's minimum intervention strategy for inspections (MISI) which aims to optimize the impact of inspections on operational availability and costs. It does this by assessing alternative inspection approaches like robot-deployed inspections of vessels and tanks, non-intrusive inspections, permanently installed sensors, and enhanced risk-based inspections to eliminate corrosion threats and optimize corrosion control. The document outlines Shell's non-intrusive inspection methodology and discusses challenges of inspecting large areas and obstacles, as well as developments in robotic inspections and permanently installed sensors that can replace traditional inspections.