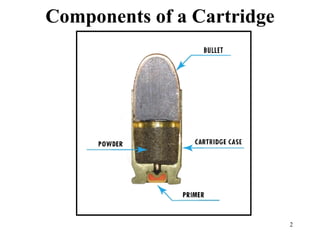

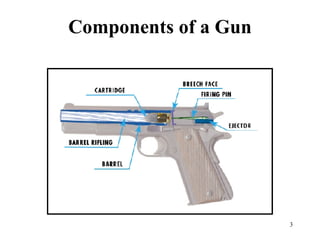

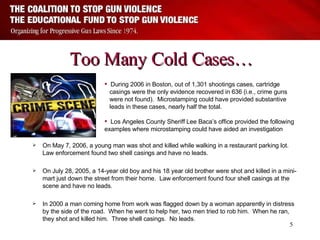

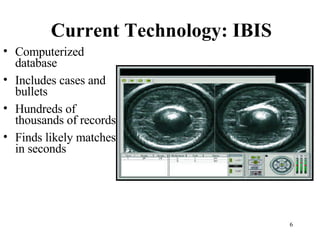

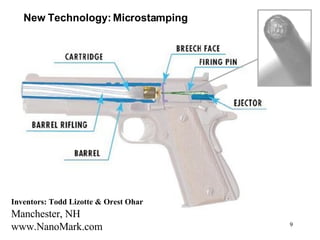

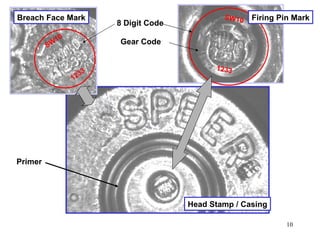

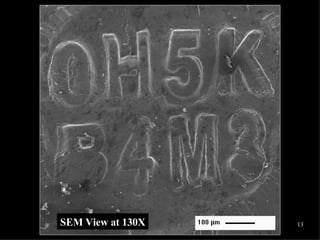

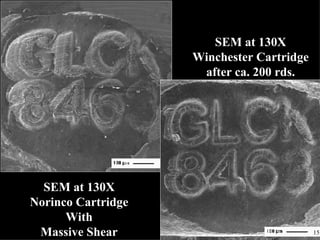

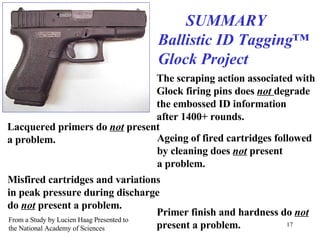

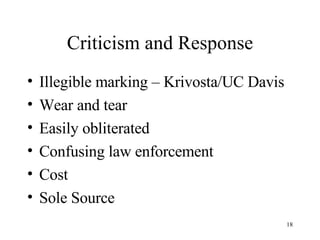

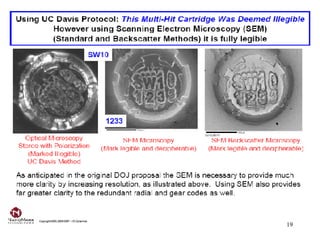

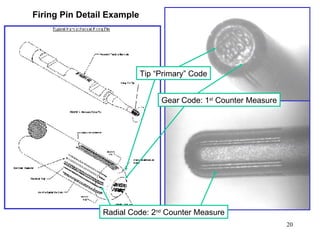

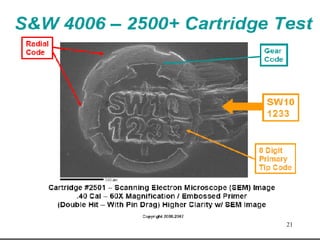

This document discusses microstamping technology that could help solve gun crimes. Microstamping inserts unique codes in the firing pin and breech face of a gun that are transferred to cartridge casings when the gun is fired. Recovered casings from crime scenes could then provide investigative leads without needing to search databases. The technology has been tested and shown to withstand thousands of rounds without degrading the stamped codes. While some criticisms have been raised, studies found the technology could help solve nearly half of Boston's 2006 shooting cases that currently have no leads.

![Cracking the Case: Microstamping Joshua Horwitz Educational Fund to Stop Gun Violence [email_address]](https://image.slidesharecdn.com/microstamping-1195503586314194-4/85/Microstamping-1-320.jpg)