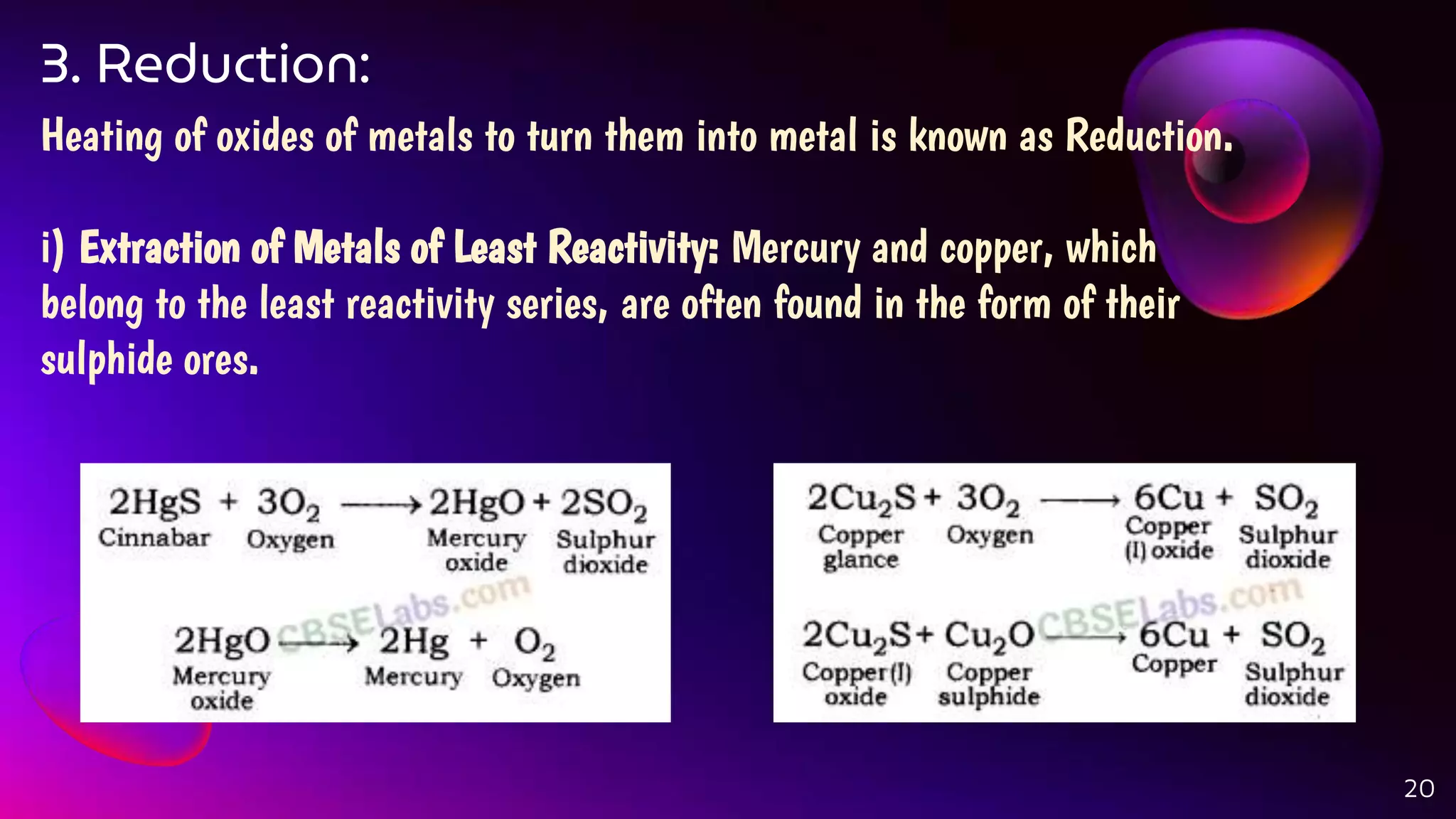

The document provides an overview of the properties and reactions of metals and non-metals, detailing their physical and chemical characteristics, reactions with oxygen, water, acids, and each other. It also covers the extraction of metals from ores, including methods like roasting, calcination, reduction, and refining. Additionally, it discusses corrosion, particularly rusting, and prevention methods, as well as the composition of various alloys.

![2005

Alloy: The homogeneous mixture of two or more

metals, or a metal and a non-metal is called Alloy.

2008 2010

Ferrous

alloys:

Manganese steel (Fe =

86% ; Mn = 13% ; C = 1%)

Non-

ferrous

alloys:

Brass (Cu = 80% ; Zn =

20%), Bronze (Cu = 90% ;

Sn = 10%)

Amalgams:

Sodium amalgams

[Na(Hg)] and Zinc

amalgams [Zn(Hg)]

27](https://image.slidesharecdn.com/metalsandnon-metals-chem1-230827065539-a7ec2ce9/75/Metals-and-Non-metals-Chem-pptx-27-2048.jpg)