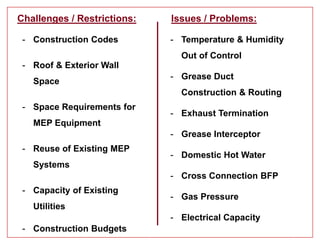

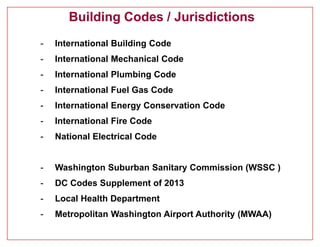

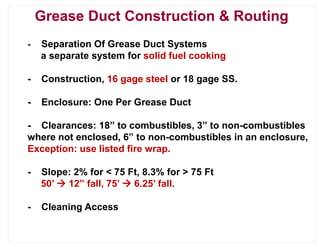

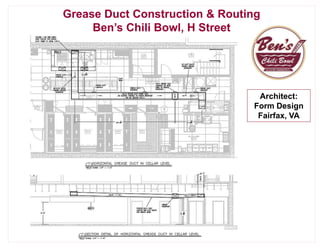

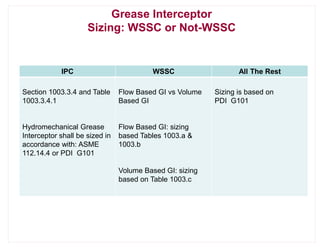

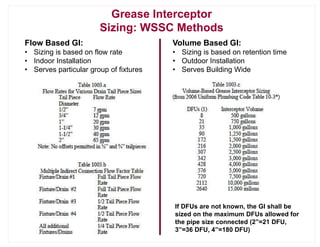

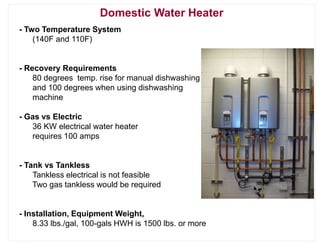

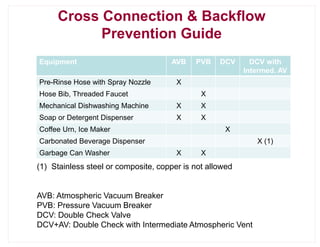

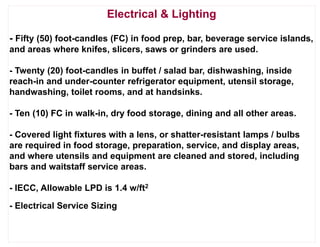

This document summarizes key mechanical, electrical, and plumbing (MEP) considerations and challenges for restaurant design. It outlines issues related to construction codes and space restrictions, then provides guidance on ensuring proper temperature and humidity control, designing fresh air systems, routing grease ducts correctly, sizing grease interceptors, installing domestic hot water heaters, preventing cross connections, and meeting electrical and lighting requirements. Case studies of specific restaurant projects are presented to illustrate best practices.