Flexeon reverse osmosis systems are engineered for commercial and light industrial applications, offering capacities from 500 to 40,000 gallons per day and designed for municipal and well water. The systems come pre-assembled, fully tested, and ready for immediate use, highlighting their reliability and cost-effectiveness. Numerous options and upgrades are available, including various membrane types, configurations, and added features such as permeate pumps and ultraviolet light for enhanced water purification.

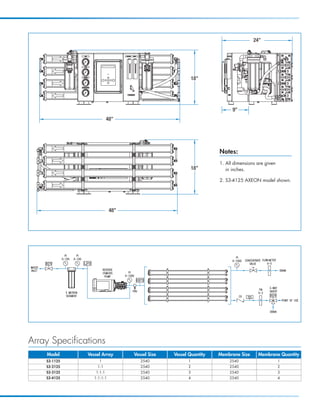

![Notes:

1. All dimensions are given in inches

and [centimeters].

2. R1-6140 AXEON model shown.

1.75”

61”

3”

25”

26” 33” 25”

CONCENTRATE RECYCLE VALVE

FM

0-100 PI x2 FLOW METER 0-300 PI CONCENTRATE

SOV LPS CONCENTRATE RECYCLE VALVE FM

HF4 MEMBRANES

WATER INLET

0-300 PI FLOW METER

CONCENTRATE DRAIN

20” FILTER

HOUSING REVERSE OSMOSIS

PUMP TDS

5 MICRON CV FM

POINT

SEDIMENT OF USE

FLOW METER

PERMEATE

Array Specifications

Model Vessel Array Vessel Size Vessel Quantity Membrane Size Membrane Quantity

R1-1140 1 4040 1 4040 1

R1-2140 1:1 4040 2 4040 2

R1-3140 1:1:1 4040 3 4040 3

R1-4140 1:1:1:1 4040 4 4040 4

R1-5140 1:1:1:1:1 4040 5 4040 5

R1-6140 1:1:1:1:1:1 4040 6 4040 6](https://image.slidesharecdn.com/membranesystems-121023050532-phpapp02/85/Membrane-systems-41-320.jpg)

![64”

100” 31”

26”

Notes:

1. All dimensions are given in inches and

[centimeters].

47”

2. Model M1-12240 AXEON model shown.

96”

FM

FEED 0-100 REVERSE OSMOSIS CONCENTRATE RECYCLE

VALVE PI PUMP FLOW METER

WATER INLET

HF4 MEMBRANES 0-300

0-100 PI

PI LPS 0-300 PI FM

FLOW METER

CONCENTRATE

5 MICRON DRAIN

BAG FILTER

TDS

CV FM

FLOW METER POINT

PERMEATE OF USE

Array Specifications

Model Vessel Array Vessel Size Vessel Quantity Membrane Size Membrane Quantity

M1-4240 1:1:1:1 4080 4 4040 8

M1-6240 2:2:1:1 4080 6 4040 12

M1-8240 3:3:2 4080 8 4040 16

M1-10240 3:3:2:2 4080 10 4040 20

M1-12240 3:3:2:2:2 4080 12 4040 24](https://image.slidesharecdn.com/membranesystems-121023050532-phpapp02/85/Membrane-systems-45-320.jpg)

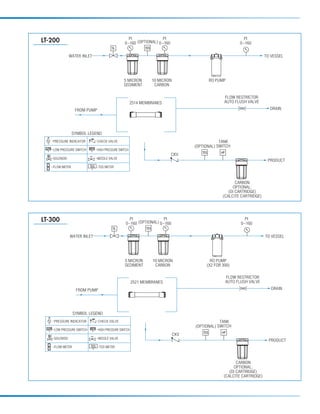

![AXEON_MKTF–109_R2_PB_Page 3 3/5/12 4:33 P

Notes:

1. All dimensions are given in inches and

[centimeters].

2. R2-6140 AXEON model shown.

1.75”

61” 3”

25”

26” 37” 25”

0-100 PI x2 0-600 PI CONCENTRATE

SOV LPS TDS VALVE FM

FILMTEC LCLE MEMBRANES

WATER INLET

0-600 PI FLOW METER

HPS

CONCENTRATE

20” FILTER DRAIN

HOUSING

REVERSE OSMOSIS

PUMP CV TDS

5 MICRON CV FM

POINT

SEDIMENT OF USE

FLOW METER

PERMEATE

Array Specifications

Model Vessel Array Vessel Size Vessel Quantity Membrane Size Membrane Quantity

R2-1140 1 4040 1 4040 1

R2-2140 1:1 4040 2 4040 2

R2-3140 1:1:1 4040 3 4040 3

R2-4140 1:1:1:1 4040 4 4040 4

R2-5140 1:1:1:1:1 4040 5 4040 5

R2-6140 1:1:1:1:1:1 4040 6 4040 6](https://image.slidesharecdn.com/membranesystems-121023050532-phpapp02/85/Membrane-systems-49-320.jpg)

![AXEON_MKTF–116_M2_PB_Page 3 3/16/12 2:17 PM

64”

100” 31”

26” Notes:

1. All dimensions are given in inches and

[centimeters].

47”

2. Model M2-12240 AXEON model shown.

96”

FEED 0-100 REVERSE OSMOSIS

VALVE PI PUMP

WATER INLET

FILMTEC® LCLE MEMBRANES 0-600

0-100 0-600 PI

PI LPS HPS PI FM

CONCENTRATE

FLOW METER

5 MICRON DRAIN

BAG FILTER

TDS

CV FM

PERMEATE POINT

FLOW METER OF USE

Array Specifications

Model Vessel Array Vessel Size Vessel Quantity Membrane Size Membrane Quantity

M2-4240 2:2 4080 4 4040 8

M2-6240 2:2:2 4080 6 4040 12

M2-8240 3:3:2 4080 8 4040 16

M2-10240 3:3:2:2 4080 10 4040 20

M2-12240 3:3:2:2:2 4080 12 4040 24](https://image.slidesharecdn.com/membranesystems-121023050532-phpapp02/85/Membrane-systems-53-320.jpg)