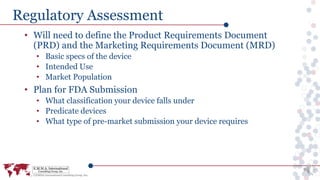

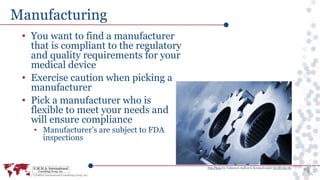

This document provides an overview of a webinar discussing efficient medical device product development processes that align quality, regulatory, and business needs. It emphasizes the importance of defining product requirements, understanding regulatory submissions, and selecting compliant manufacturers. Additionally, it covers post-commercialization considerations and how experts can assist in navigating the complexities of medical device development.

![Product Requirements:

• Will define device’s

intended use, features,

and functionality

• Requirements should be

specific and measurable

• Will tie into design

controls and User Needs

traceability[1]

Regulatory Assessment: Developing Requirements

This Photo by Unknown Author is licensed under CC BY-SA-NC](https://image.slidesharecdn.com/productdevelopmentwebinarv2-200411194600/85/Medical-Device-Product-Development-8-320.jpg)

![Regulatory Assessment: Planning for FDA Submission

• Determine what premarket

submission type, if any, is required

for your device

• 510(k) (Premarket Notification)

• PMA (Premarket Approval)

• De Novo Classification Request

• Determine what requirements your

device will have to comply with[2]

• Design Controls

• Clinical Testing

This Photo by Unknown Author is licensed under CC BY-SA-NC](https://image.slidesharecdn.com/productdevelopmentwebinarv2-200411194600/85/Medical-Device-Product-Development-10-320.jpg)

![Manufacturing:Various Requirements

• There are several different types

of assembly and environments

your device may require

• ISO 14644-1 Cleanrooms and

associated controlled

environments[3]

• Overmolding for medical devices

• Medical device assembly

precision

• A robust QMS will need to be

built for device manufacturing](https://image.slidesharecdn.com/productdevelopmentwebinarv2-200411194600/85/Medical-Device-Product-Development-12-320.jpg)

![Regulatory Submission: Acceptance Review

• “Is the Submission with the

appropriate Center?”

• “Submission contains a Table of

Contents”

• “Each Section is Labeled”

• File type is also important (PDF vs.

Word)

• Each file must follow a specific

naming convention

• 180 day deadline for re-

submission[4]

This Photo by Unknown Author is licensed under CC BY-SA](https://image.slidesharecdn.com/productdevelopmentwebinarv2-200411194600/85/Medical-Device-Product-Development-15-320.jpg)

![Commercialization

• MDSAP: Australia, Brazil, Canada,

Japan, U.S.

• Harmonized to 13485: 2016[5]

• More robust than 21 CFR 820

• More ties to ISO 14971 (Risk

Management)[6]](https://image.slidesharecdn.com/productdevelopmentwebinarv2-200411194600/85/Medical-Device-Product-Development-17-320.jpg)

![[7]](https://image.slidesharecdn.com/productdevelopmentwebinarv2-200411194600/85/Medical-Device-Product-Development-18-320.jpg)