1. The document describes the operations and processes at Medco Singa CPP, an LNG processing facility in South Sumatra. It separates and purifies natural gas from four wells.

2. The CPP consists of several gas processing units including separation, acid gas removal, and dehydration systems. It also has supporting utilities like thermal fluid and water treatment systems.

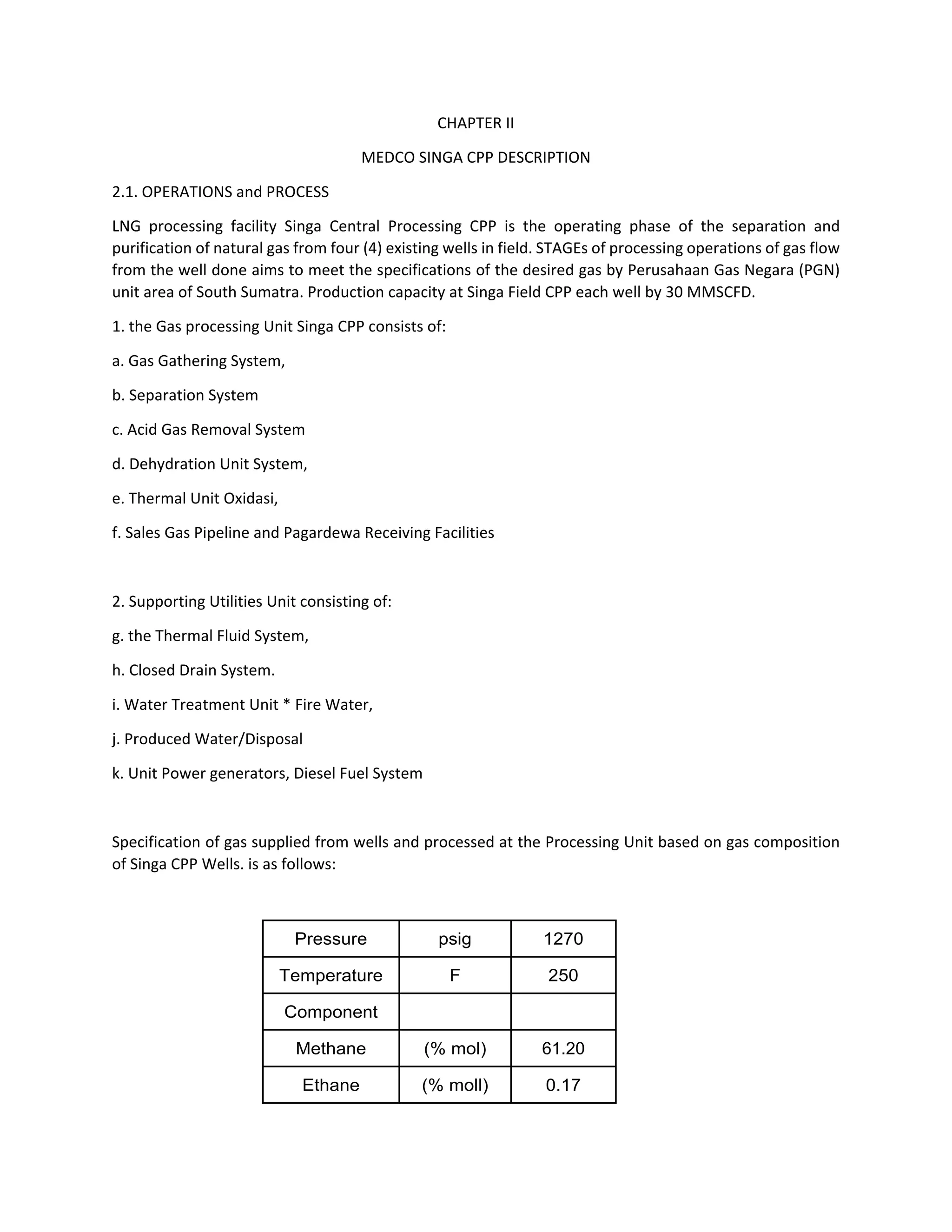

3. The raw gas from the wells is processed to meet specifications for delivery to PGN, including reducing CO2 levels from 38% to 4% and H2S from 0.03% to 4 ppm. This is achieved through amine absorption and membrane units in the acid gas removal section.