This document provides a 3-sentence summary of the Wire V9 tutorial:

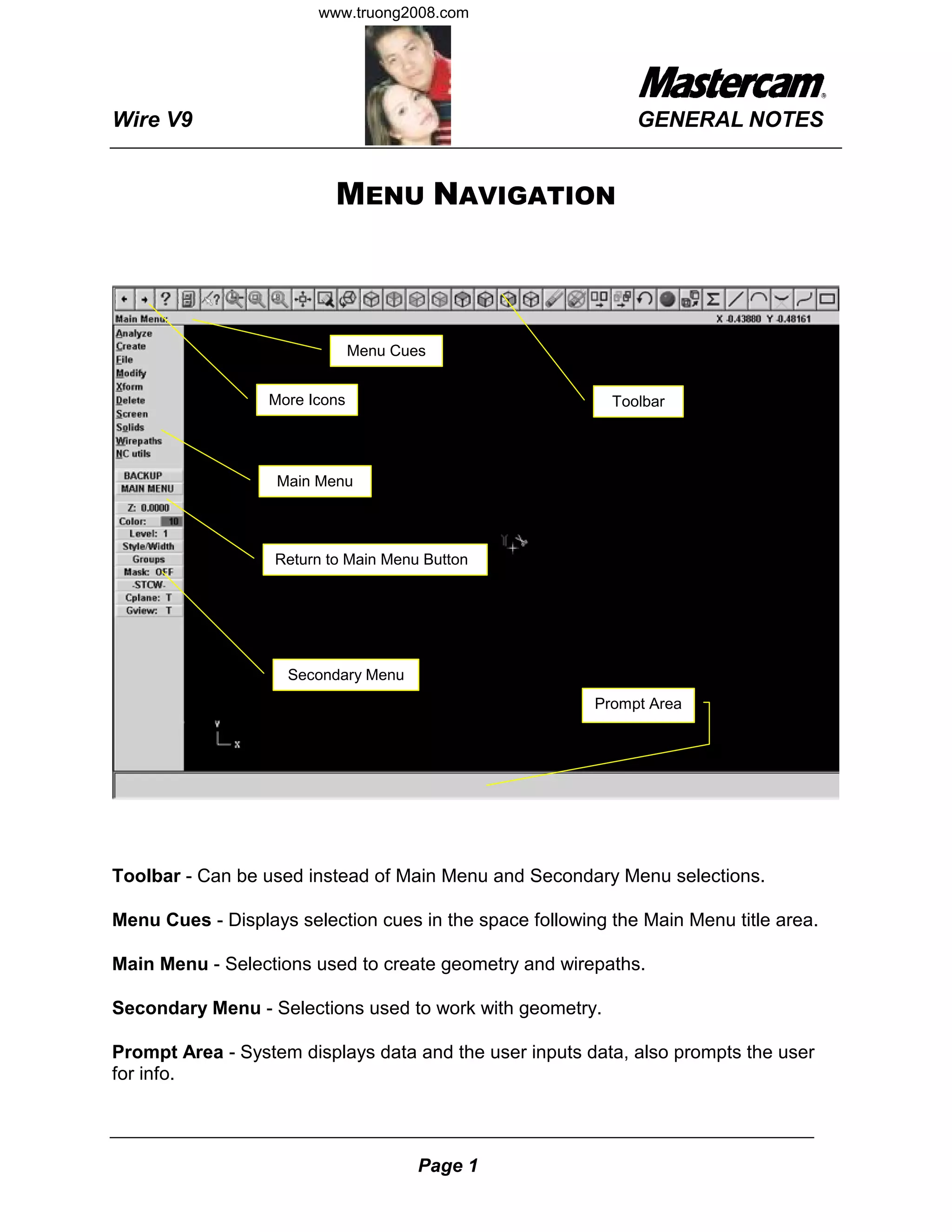

The tutorial covers the main menu, secondary menu, and other interface elements of Wire V9 such as toolbars, menus, and prompt areas for inputting data. It also describes functions for creating and modifying geometry, transforming objects, and programming wirepaths. Default key bindings are listed to navigate the interface and access common commands.

![Wire V9 GENERAL NOTES

ASSIGNING BUTTONS AND KEYS

This Mastercam feature lets you assign a function or C-Hook or macro to a function key

(F1 through F10) or an Alt key (excluding system keys such as Alt+F4) or a button in

Mastercam's Toolbar. You can assign a maximum of 50 keys and a maximum of 99

buttons.

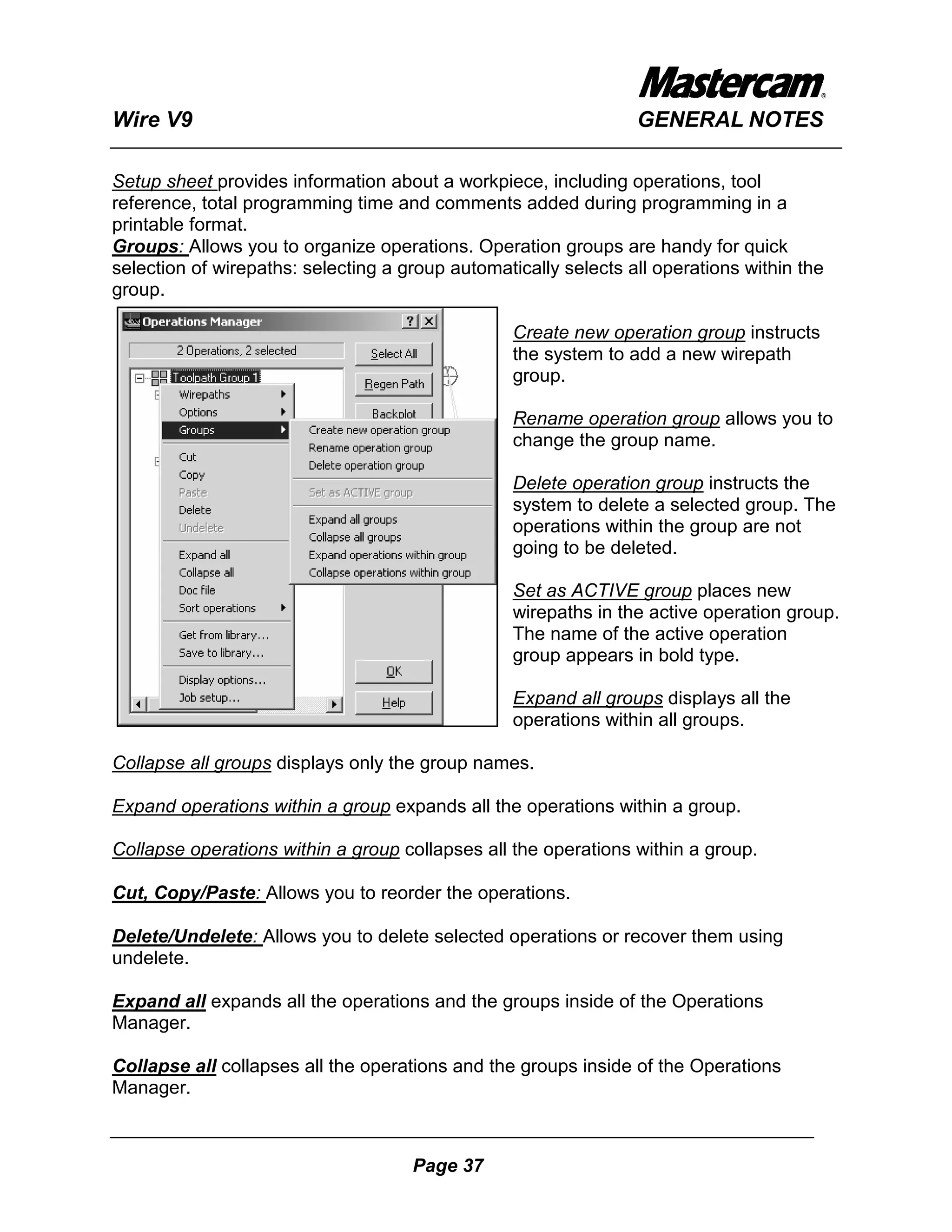

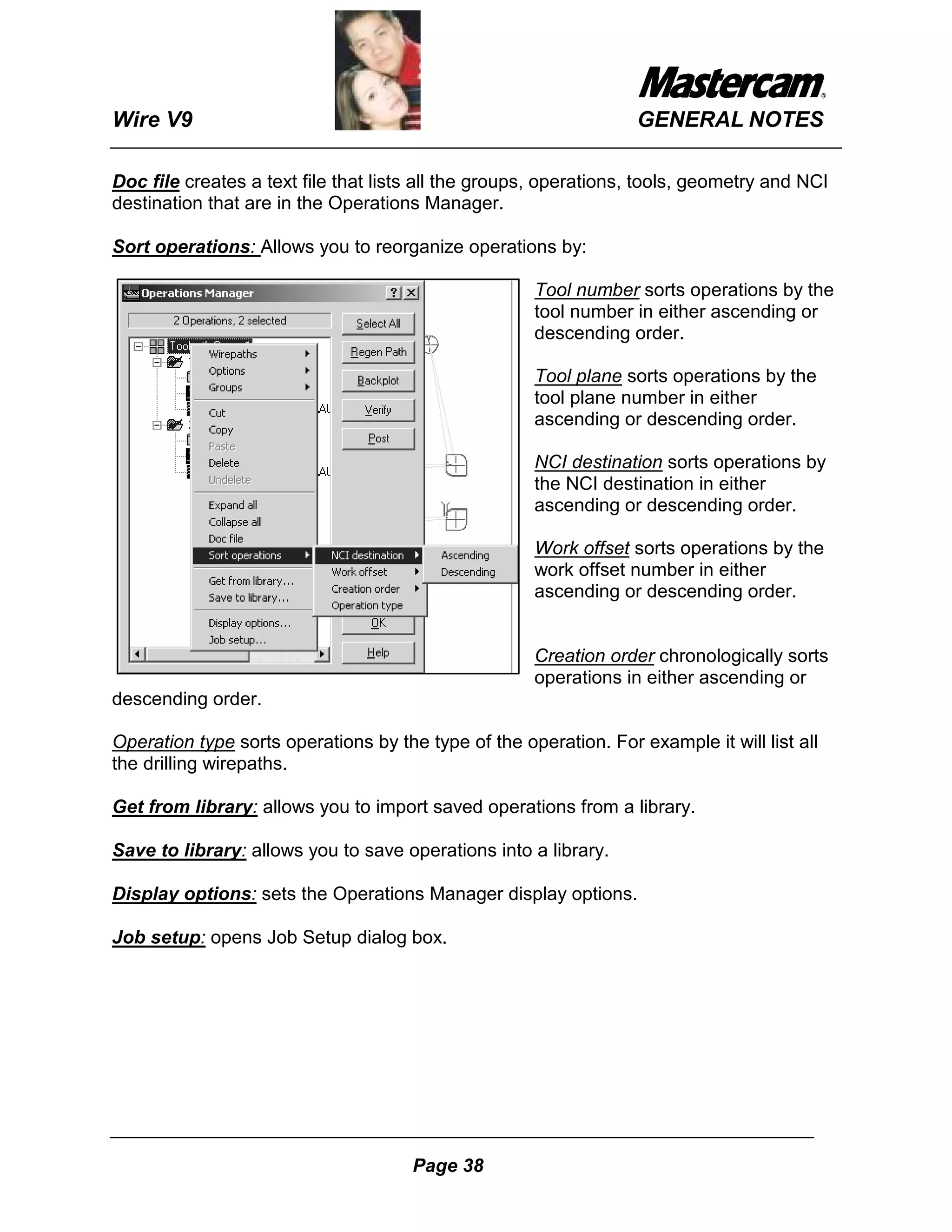

Select the following menu picks:

MAIN MENU

Screen

Configure

Toolbar/ Keys

Funcs/ C-Hooks/ Macros [default]

This allows the user to check all assignments, or filter out the desired

commands. ( Functions, c-hooks, macros, keys, buttons, keys/ buttons).

All [default]

This function allows the user to further filter using the following variables:

Unassigned, assigned, all.

Find Key

This function allows the user to press a button or key, and the function assigned

to it will be filtered out.

Current Assignment

Add This allows the user to add an assignment.

Edit This allows a user to edit an existing assignment.

Remove This allows the user to remove an assignment.

Page 10](https://image.slidesharecdn.com/master-cam-9-090805004820-phpapp01/75/Master-Cam-9-11-2048.jpg)