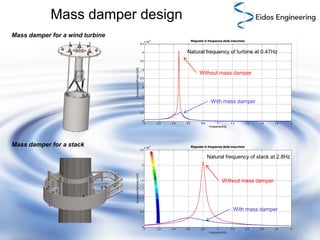

Eidos Engineering develops mass dampers, which are vibration absorbers that significantly reduce vibrations in various structures and machines, thereby enhancing global damping. These devices can be customized for a wide range of applications, including tool machines, bridges, and wind turbines, with advantages such as up to 70% vibration reduction and increased structural security. The document also highlights the mass dampers' effectiveness through frequency response graphs and dynamic analysis during seismic events.

![Mass damper development

A mass damper is a vibration absorber able to attenuate significantly the

vibrations of a structure or a machine.

In the graph we report the frequency response of a machine with and

without mass damper. The application of a mass damper gives an

important increment of the global damping.

Mass damper action

0.9

without mass damper

with mass damper

0.8

Displacement [mm]

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0

300

600

900

1200

1500

Rotor speed [rpm]

Frequency response measured on a vibrating machine

1800](https://image.slidesharecdn.com/massdampervibrationabsorber-140208040955-phpapp02/85/Mass-damper-vibration-absorber-2-320.jpg)

![Mass damper for structures

Displacement [m]

without tuned mass damper

Time [s]

Dynamic analysis of a three

stories structure.

The

graphs

show

the

displacements

of

the

structure under the 1976

Friuli earthquake without the

application of a mass damper

and with a mass damper

placed at top.

Displacement [m]

with tuned mass damper

Time [s]

Friuli 1976 – Buja seismic station

Displacement of the structure at top](https://image.slidesharecdn.com/massdampervibrationabsorber-140208040955-phpapp02/85/Mass-damper-vibration-absorber-7-320.jpg)