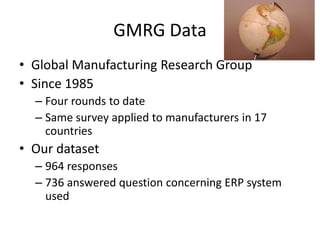

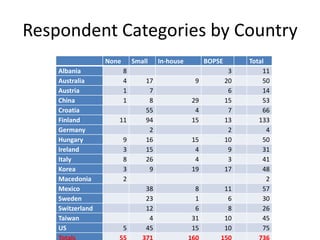

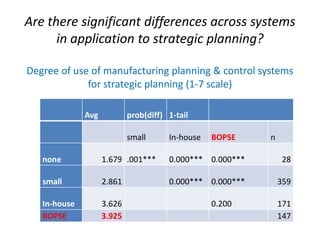

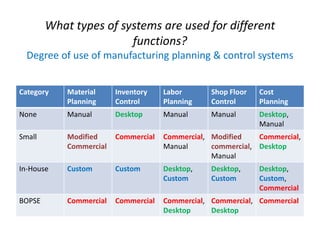

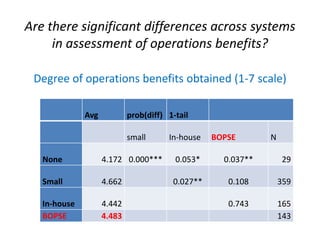

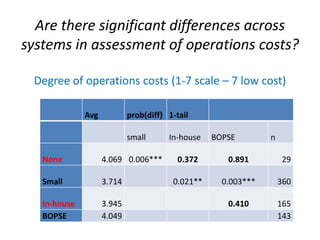

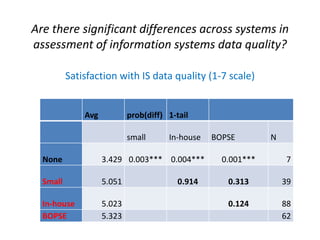

The document discusses the evolution and application of manufacturing planning systems (MPS) from the 1960s to the 1990s, highlighting the differences in strategic planning effectiveness among various system types. It presents data from a global survey involving 964 manufacturers, revealing that vendor systems generally offer better performance benefits and data quality compared to in-house systems, although both have their roles. The conclusions emphasize the varying functionalities of MPS and the distinct advantages of major vendor systems, especially in strategic planning contexts.