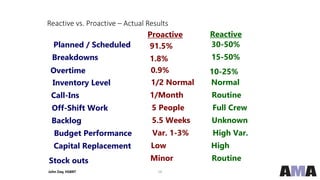

This document provides an overview of maintenance planning and scheduling. It discusses the importance of planning to increase productivity and proactive maintenance. The key principles of planning include having dedicated planners, focusing on future work, maintaining equipment files, leveraging experience to develop plans, recognizing trade skills, and measuring performance. Effective scheduling follows principles like developing weekly work schedules based on priorities and plans, and daily scheduling to match tasks to skills. The overall goal is to increase efficiency and effectiveness through organized, planned work.