The document discusses the lost foam casting process which involves:

1) Expandable polystyrene beads being heated and fused to create a mold,

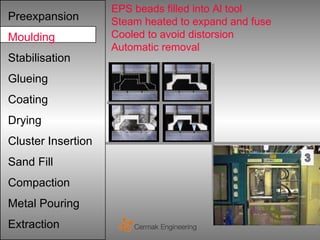

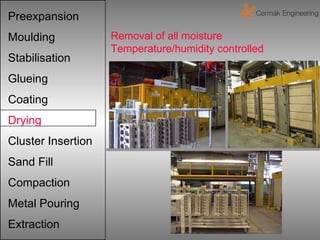

2) The mold is then cooled to prevent distortion before stabilizing and coating treatments,

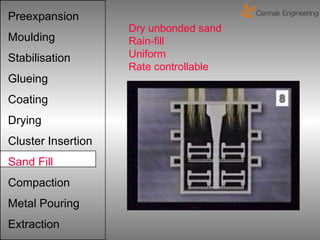

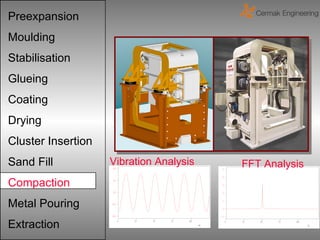

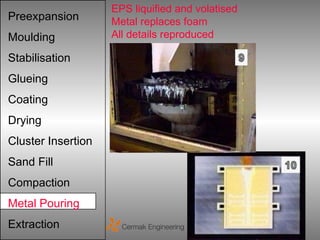

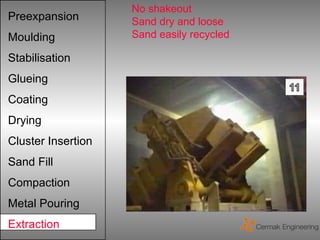

3) Sand is then packed around the mold and compacted before metal is poured, replacing the polystyrene which liquifies and volatizes, accurately reproducing all details.