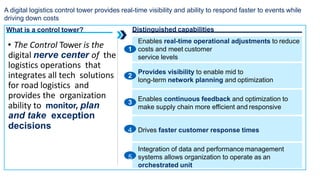

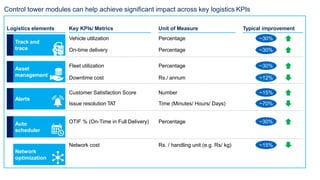

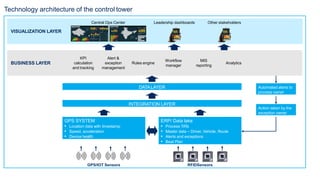

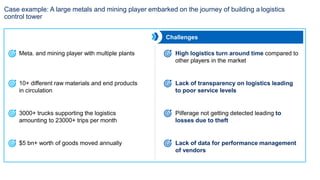

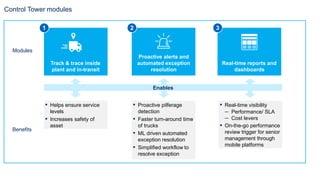

This document discusses the benefits of implementing a logistics control tower. It begins by outlining common issues that plague logistics in India, such as poor transit times and lack of visibility. These issues significantly impact organizations through increased costs and reduced service levels. The document then introduces the concept of a digital logistics control tower, which provides real-time visibility and control to help reduce costs and improve response times. It describes the key modules of a control tower and how they can be implemented over different time horizons. Case studies demonstrate how control towers have helped companies achieve improvements in metrics like vehicle utilization and on-time delivery. The last sections discuss the technology architecture and debunk common myths about control towers.