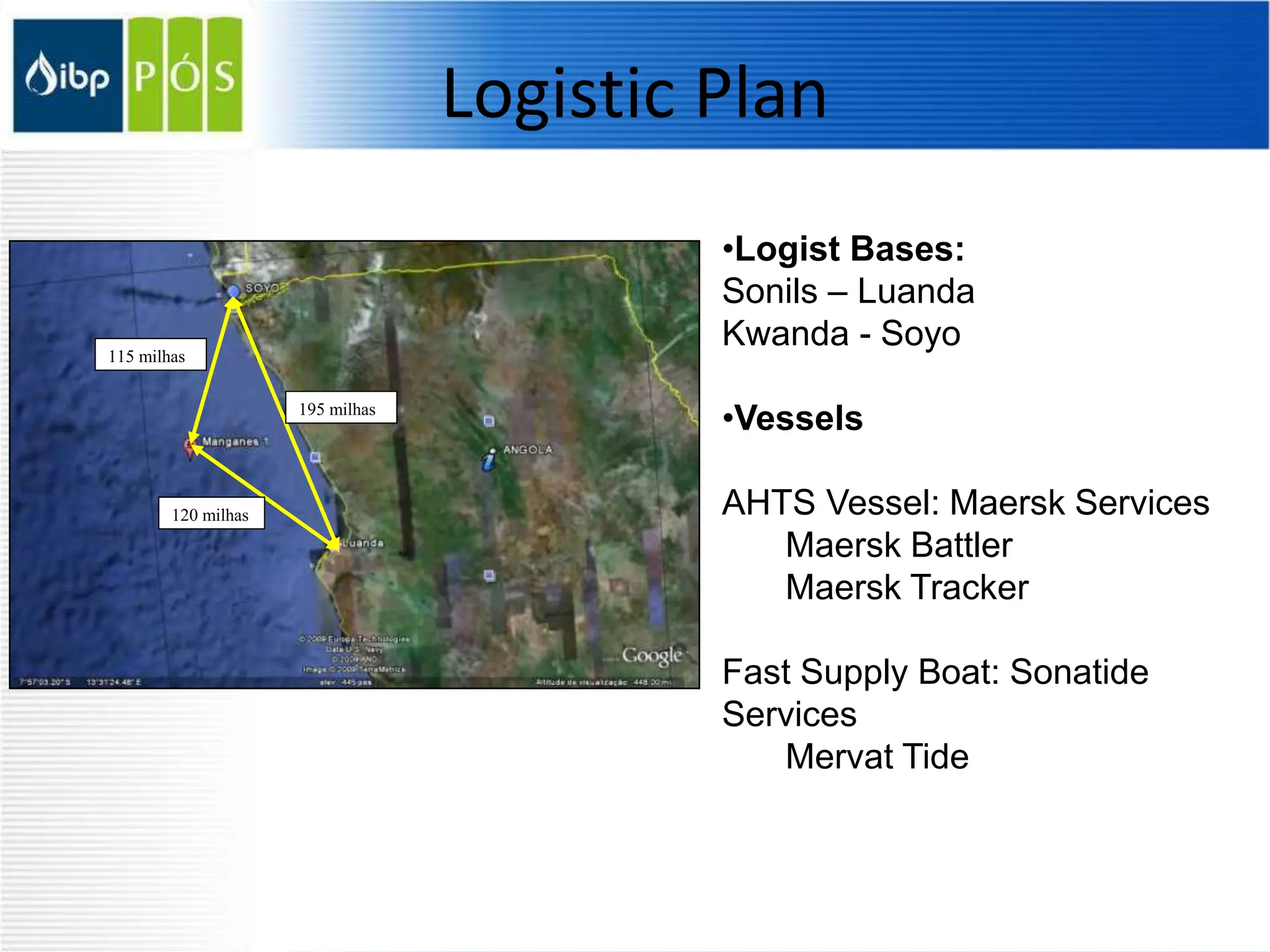

The document outlines the logistic procedures for the Block 99 drilling campaign, detailing transportation logistics for personnel and materials in offshore operations. It specifies vessel and airport information, personnel transport guidelines, and material transportation requirements. Additionally, it includes contact details for the drilling superintendent and logistics operations personnel.